Welded Metal Bellows Seal for Low Temperature John Crane Type 680

This specialized mechanical seal addresses the challenges of low-temperature operations and diverse industrial media. It provides optimal performance in:

• Chemical processing systems

• Oil and gas equipment

• Refinery operations

• High-viscosity pumping applications across multiple sectors

Product Overview

Its fully metallic bellows construction eliminates failures associated with dynamic elastomers, providing superior corrosion resistance and positive drive transmission. Advanced engineering distributes operational stress, extending service life under cyclic flexing conditions.

The self-cleaning design removes particles that clog spring-based seals, eliminating the need for auxiliary flushing. This configuration maintains consistent face loading while compensating for shaft misalignment, thermal movement, and wear, ensuring stable operation in demanding environments.

Equivalent Model

*Our GW 687 seal delivers precise dimensional and performance compatibility with John Crane Type 680, produced through ISO9001-certified manufacturing protocols to ensure matching operational characteristics with improved economic efficiency.

Material and Operating Range

Materials:

• Rotary Ring: Carbon, Silicon Carbide, Tungsten Carbide

• Stationary Ring: 99% Ceramic, Silicon Carbide, Tungsten Carbide

• Bellow: AM350 (Corrosion resistance comparable to Alloy-20)

• O-Ring: VITON, EPDM, or Encapsulated Ring

• Spring & Metal Parts: SUS304, SUS316

* Custom material selections and engineering modifications are available to address unique operational needs. Consult our technical department for personalized solutions.

Operating Range:

• Temperature: -75 ℃~200℃

• Pressure: ≤2.5 MPa

• Rotational Speed: ≤25 m/s

Compatible Media:

• Petroleum and natural gas products

• Water and wastewater streams

• Chemical and corrosive liquids

• Sewage and process water

• Pulp and paper processing fluids

• Utility industry process media

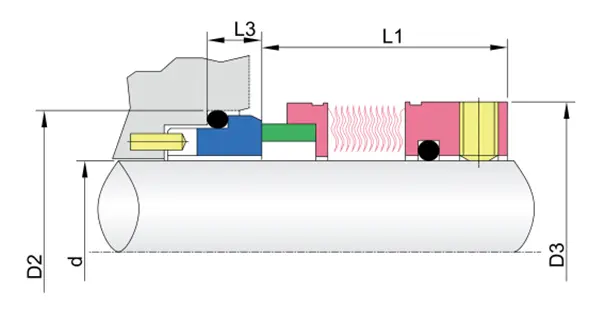

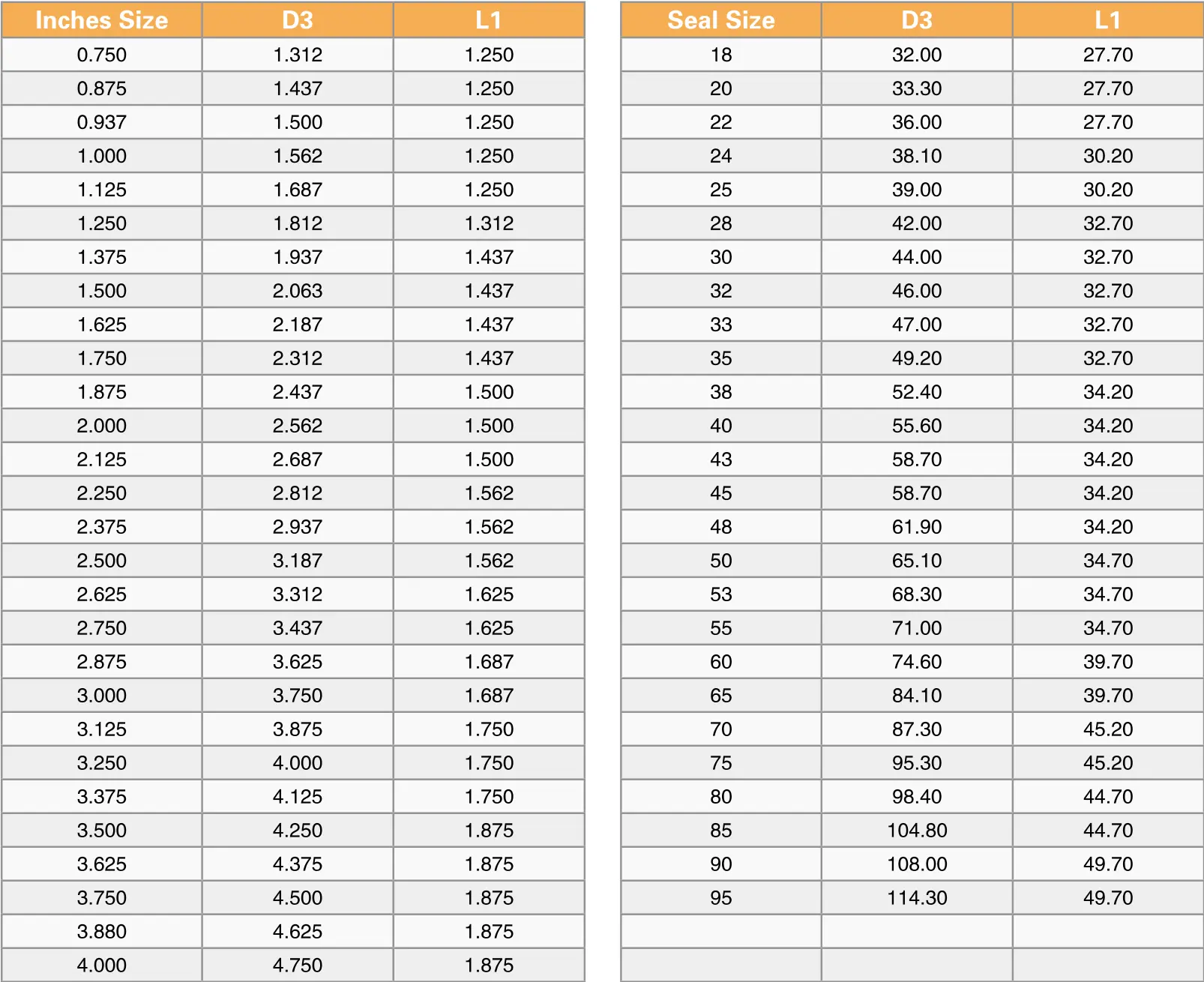

Installation Dimensions

description2