Welded Metal Bellow Mechanical Seals MFLWT80

This advanced metal bellows seal is engineered for severe service applications involving extreme thermal cycling and highly viscous media. It provides reliable performance in:

• Chemical processing industry applications

• Oil and gas processing equipment

• Refining technology operations

• High-temperature pump sealing applications

• Aggressive chemical and hydrocarbon services

Product Detail

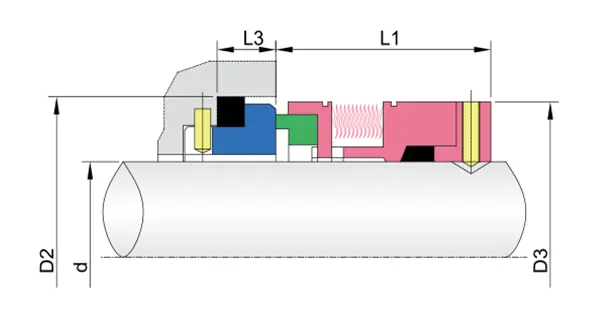

This balanced seal design features a compact configuration that reduces overall length while providing enhanced performance in high-temperature applications. The innovative bellows construction protects shaft and sleeve components from wear and scoring, with optimized notch geometry that eliminates stress concentration in the bellows plates. The stationary seal face complies with EN12756 (DIN 24960) dimensional standards for direct interchangeability.

Equivalent Products

We also provide related products including complete seal support systems. Contact our technical team for application engineering support.

*Our ISO9001-certified manufacturing ensures identical dimensional specifications and performance characteristics to the referenced OEM products, providing a reliable alternative with verified compatibility.

Material and Operating Range

Construction Materials:

• Rotary Ring: Carbon / Silicon Carbide (SiC) / Tungsten Carbide (TC)

• Stationary Ring: 99% Ceramic / SiC / TC

• Metal Bellows: AM350 stainless steel

• Secondary Sealing: Encapsulated Rings / Expanded Graphite

• Metallic Components: SUS304 / SUS316

*Custom material configurations and special designs are available for unique application requirements. Contact our engineering department for technical consultation.

Operating Parameters:

• Temperature Range: -40°C to 400°C

• Pressure Limit: ≤ 2.1 MPa

• Maximum Surface Speed: ≤ 20 m/s

Compatible Media:

• Crude oil and refined petroleum productsm

• Process water and wastewater streams

• Chemical solutions and corrosive fluids

• Pulp and paper processing media

• High-temperature thermal fluids

Installation Dimensions

description2