Unbalanced Sinusoidal Wave Seal for Johnson Top Lobe Rotary Pump

Hygienic Sealing Solutions:

This wave spring mechanical seal is highly compatible with the Johnson TopLobe (TL) 1, Johnson TopLobe (TL) 2 and Johnson TopLobe (TL) 3 pumps in demanding industries:

• Food processing lobe pumps (sauces, dressings)

• Dairy transfer seals (milk, yogurt)

• Pharmaceutical lobe rotor seals

• Viscous fluid handling systems

Product Description

• O-ring mounted sealing system with sinusoidal wave spring

• Bi-elastomeric stationary components

• Monolithic 316L steel head

Design Functionality:

• Shaft drive mechanism: Hex-key tightened set screws secure shaft connection

• Radial profile: Narrow cross-section

• Face loading: Wave spring delivers even circumferential pressure (±5% variance)

• Thermal compensation: Bi-elastomeric design accommodates ±1.5mm axial movement

Performance Benefits:

• Enhanced pV capability: 15-20% improvement over standard springs (per FSA test 2107)

• Abrasion resistance: Validated for 30μm particles in viscous media (ASTM G65 protocol)

• Installation efficiency: 25% shorter length vs. conventional lobe pump seals

Validated Applications:

• Rotary lobe pumps (≤18m/s shaft speed)

• Hygienic processing equipment

• Viscous fluid transfer systems

Equivalent Products

• Vulcan®: Type 1688Z

• EagleBurgmann®: Type M7KS60

*ISO9001-certified alternatives with 40% cost efficiency!

Material and Operating Range

Construction Materials:

• Rotary ring: SUS304/SUS316/SiC/TC

• Stationary ring: Carbon/SiC/TC

• O-ring: VITON/NBR/EPDM

• Wave spring and metal parts: SUS304/SUS316

* Customization for this part is supported, please contact us for changing parameters and materials.

Operating Envelope:

• Temperature: -40 ℃~200℃

• Pressure: ≤0.8MPa

• Speed: ≤18m/s (low-speed optimized)

• Performance: Wear

Media Compatibility:

• Edible oils & fats

• Dairy products & emulsions

• Food-grade viscous fluids

• Pharmaceutical suspensions

• Sanitary process water

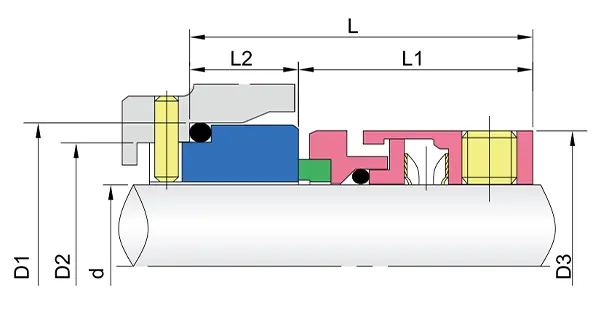

Installation Dimensions

| PUMP ref: | Size | D1 | D3 | L1 | L2 |

| 10 | 30 | 48.0 | 41.0 | 19.1 | 10.3 |

| 20 | 35 | 55.0 | 45.5 | 19.1 | 12.0 |

| 30 | 50 | 72.0 | 61.9 | 21.1 | 12.0 |

description2