Standard Dimensions and Compliance

Global standardization ensures component interoperability and reliability. Key standards include:

● DIN 24960 / EN 12756: These define precise dimensions, tolerances, and identification codes, including options for short axial dimensions, anti-rotation pin, and seat blocked ring

● European/American Standard Housing Dimensions: Designs often align with common EU/U.S. industry housing specifications, including anti-rotation slot ensuring broad compatibility with pumps and rotary equipment.

Material Selection and Performance Characteristics

For detailed material parameters please refer to

Materials and Features

.

Material choice must account for chemical compatibility, thermal stability, abrasion resistance, and mechanical strength. Common materials include:

Inquiry Now

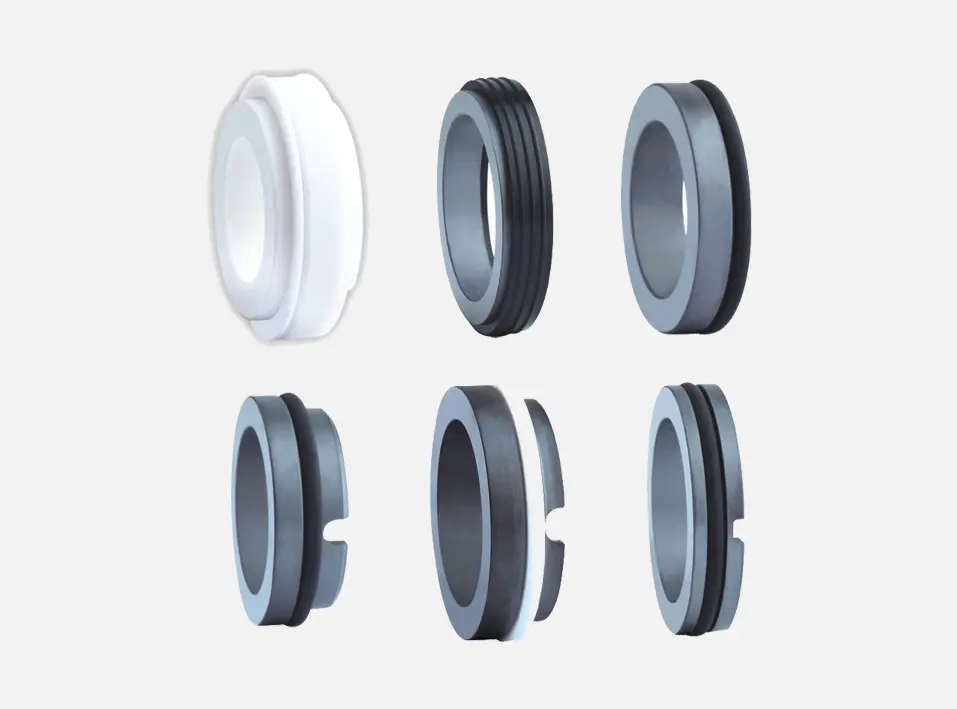

Secondary Sealing Options

An effective seal between the stationary seat and gland is critical. Beyond standard elastomer O-rings (e.g., NBR, EPDM, FKM/Viton), we have option of L-Shape Seals, PTFE Gaskets

-

OEM Equivalent Quality

We provide high-quality alternatives compatible with major brands including: Vulcan/ AESSEAL/ Burgmann/ John Crane/ Flowserve etc. -

Embroidery Customizationn

Material selection guidance based on your specific applicationCross-referencing services for OEM parts replacementCustom engineering solutions for unique requirementsTechnical consultation for optimal seal performance -

Fabric Selection and Technology

ISO 9001 certified manufacturing processesRigorous quality control at every production stageComprehensive testing and performance validationTraceability and documentation for all materials

-

Detailed material properties and performance data

-

Standard and custom dimension specifications

-

Cross-reference guides for major OEM parts

-

Application recommendations and selection guidelines

-

Technical drawings and installation instructions

-

Download Now to access comprehensive engineering data for your sealing solutions.

Need Immediate Support or Customized Solutions?

Our engineering team is ready to assist with application-specific challenges, material recommendations, and custom-designed stationary components. Contact our technical experts for personalized support and quotation requests.