Stainless Steel Head Single Spring Seal Replacement Vulcan 8

Industrial Performance:

Engineered for industrial centrifugal pump seals in chemical and oil refinery applications, this corrosion-resistant stainless-steel mechanical seal delivers:

• Reliable acid/alkali transfer sealing for chemical processes

• Robust boiler feed water pump sealing under harsh operation conditions

• Durable abrasive slurry pump mechanical sealing

• Leak-proof hot oil pump operation in refinery services

Product Description

• Vibration Damping: VITON®/EPDM Chemical-resistant elastomers absorb axial movement in mixer shaft sealing

• Precision Contact: Conical spring mechanism consistently maintains rotary seal face pressure

• Cartridge Installation: Quick in-pump seal replacement without dismantling

This medium to heavy-duty single spring seal is ideal for centrifugal pump seal replacement in demanding applications: refinery process pumps, chemical processing systems, and abrasive slurry transfer equipment.

Equivalent Products

• Roten®: L4B

• Vulcan®: Type 8

• EagleBurgmann®: M32/M377

• Sterling®: SM32

• Flowserve®: Type 38

• Lidering®: 109/LS19/PFL4

• U.S. Seal®: VGME-2/VGM-G4

We provide mechanical seal solutions with identical dimensions, ISO9001 quality, and 30% cost savings.

Material and Operating Range

Material:

• Rotary ring: Carbon/SiC/TC

• Stationary ring: 99%Ceramic/SiC/TC

• Elastomer elements (O-ring): VITON/NBR/EPDM

• Spring and Metal Parts: SUS304/SUS316

* Customization for this part is available, please consult our engineering team for changing parameters and materials.

Operating Range:

• Temperature: -30 ℃~200℃

• Pressure: ≤1.2MPa (Medium pressure)

• Speed: ≤20m/s (General Speed)

• Performance: Moderately corrosive

Compatible Mediums:

• Crude and refined oils

• Boiler feed water

• Acids/alkalis

• Alkali

• Salt brines and crystallizing fluids

• Organic solvent mixtures

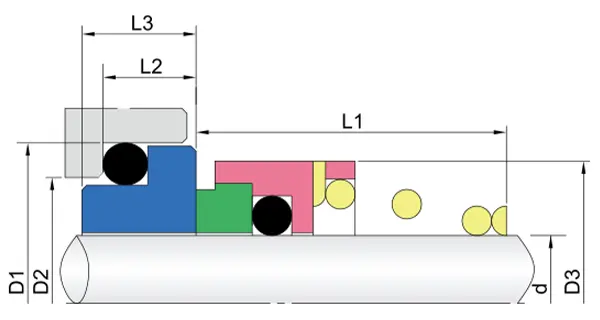

Installation Dimensions

| Seal Size d | D1 | D2 | D3 | L1 | L2 | L3 |

| 10 | 21.0 | 17.0 | 19.0 | 15.5 | 6.6 | 7.5 |

| 12 | 23.0 | 19.0 | 21.0 | 15.5 | 5.6 | 7.5 |

| 14 | 25.0 | 21.0 | 23.0 | 15.5 | 5.6 | 7.5 |

| 16 | 27.0 | 23.0 | 26.0 | 17.5 | 6.6 | 7.5 |

| 18 | 33.0 | 27.0 | 29.0 | 18.5 | 7.5 | 8.5 |

| 20 | 35.0 | 29.0 | 31.0 | 20.0 | 7.5 | 8.5 |

| 22 | 37.0 | 31.0 | 33.0 | 21.5 | 7.5 | 8.5 |

| 25 | 40.0 | 34.0 | 36.0 | 24.5 | 7.5 | 8.5 |

| 28 | 43.0 | 37.0 | 40.0 | 24.5 | 7.5 | 8.5 |

| 30 | 45.0 | 39.0 | 43.0 | 24.5 | 7.5 | 8.5 |

| 32 | 48.0 | 42.0 | 46.0 | 28.0 | 7.5 | 8.5 |

| 35 | 50.0 | 44.0 | 49.0 | 28.0 | 7.5 | 8.5 |

| 38 | 56.0 | 49.0 | 53.0 | 31.0 | 9.0 | 10.0 |

| 40 | 58.0 | 51.0 | 56.0 | 34.0 | 9.0 | 10.0 |

| 43 | 61.0 | 54.0 | 59.0 | 35.0 | 9.0 | 10.0 |

| 45 | 63.0 | 56.0 | 61.0 | 36.5 | 9.0 | 10.0 |

| 48 | 66.0 | 59.0 | 64.0 | 42.0 | 9.0 | 10.0 |

| 50 | 70.0 | 62.0 | 66.0 | 43.0 | 9.5 | 10.5 |

| 55 | 75.0 | 67.0 | 71.0 | 47.0 | 11.0 | 12.0 |

| 58 | 78.0 | 70.0 | 76.0 | 50.0 | 11.0 | 12.0 |

| 60 | 80.0 | 72.0 | 78.0 | 51.0 | 11.0 | 12.0 |

| 65 | 85.0 | 77.0 | 84.0 | 52.0 | 11.0 | 12.0 |

| 68 | 90.0 | 81.0 | 88.0 | 53.0 | 11.3 | 12.5 |

| 70 | 92.0 | 83.0 | 90.0 | 54.0 | 11.3 | 12.5 |

| 75 | 97.0 | 88.0 | 98.0 | 55.0 | 11.3 | 13.0 |

| 80 | 105.0 | 95.0 | 100.0 | 58.0 | 12.0 | 15.0 |

description2