Single Spring Elastomer Bellow shaft seal Replace Vulcan 10

This versatile elastomer bellow mechanical seal is engineered for a broad spectrum of service conditions, from water and steam to various chemicals and corrosive media. Ideal for mechanical seal replacement in light to medium duty rotating equipment, specifically designed for:

• Water pump mechanical seals in wastewater systems• Pump shaft seals and centrifugal pump mechanical seals in industrial applications

• Pump mechanical seals for pulp & paper industry

• Chemical process pump seals

Product Detail:

Validated Equipment Compatibility:

• Allweiler SNH 120

• Crane 2C GBC, Crane 5B GBR

• Flowserve 2 1/2 LR-10, Flowserve 2 1/2 LR-13

• Others rotating equipment

*Its stationary suits common metric and imperial UK and European extended length seal chambers.

Equivalent Products

• Vulcan®: Type 10

• JohnCrane®: Type 521

• EagleBurgmann®: Type MG910

• Flowserve Pac Seal®: Type 240

• Sterling®: Type 522

• Roten®: Type 52

*Cost-effective mechanical seal alternative offering OEM mechanical seal quality with ISO9001 certification.

Material and Operating Range

Material:

• Rotary ring: Carbon/ Silicon carbide (SiC) / Tungsten Carbide (TC)

• Stationary ring: 99% Ceramic /SiC/TC

• O-ring: VITON/NBR/EPDM

• Spring and Metal Parts: SUS304/SUS316

* Base plate can be removed if required

* Custom configurations available for special requirements.

Operating Range:

• Temperature: -40 ℃~180℃

• Pressure: ≤1.0 MPa

• Speed: ≤15 m/s

• Performance: Less wear

Mediums:

• Oils and lubricants

• Water and steam

• Sewage and wastewater

• Pulp and paper slurries

• Food

• Various chemical solutions

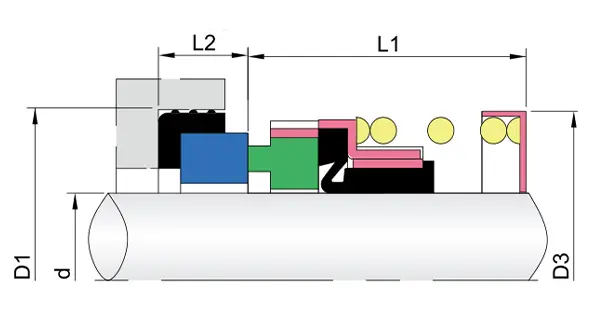

Installation Dimensions

| Seal Size d | D1 | D3 | L1 | L2 |

| 12 | 27.79 | 23.50 | 43.66 | 8.74 |

| 13 | 27.79 | 23.50 | 43.66 | 8.74 |

| 14 | 30.95 | 27.00 | 43.66 | 10.32 |

| 15 | 30.95 | 27.00 | 43.66 | 10.32 |

| 16 | 30.95 | 27.00 | 43.66 | 10.32 |

| 18 | 34.15 | 30.70 | 43.66 | 10.32 |

| 19 | 34.15 | 30.70 | 43.66 | 10.32 |

| 20 | 35.70 | 33.40 | 43.66 | 10.32 |

| 22 | 37.30 | 33.40 | 43.66 | 10.32 |

| 24 | 40.50 | 39.20 | 43.66 | 10.32 |

| 25 | 40.50 | 39.20 | 43.66 | 10.32 |

| 28 | 47.63 | 45.60 | 60.33 | 11.99 |

| 30 | 50.80 | 47.40 | 60.33 | 11.99 |

| 32 | 50.80 | 47.40 | 60.33 | 11.99 |

| 33 | 53.98 | 52.00 | 60.33 | 11.99 |

| 34 | 53.98 | 52.00 | 60.33 | 11.99 |

| 35 | 53.98 | 52.00 | 60.33 | 11.99 |

| 38 | 57.15 | 55.60 | 60.33 | 11.99 |

| 40 | 60.33 | 59.20 | 60.33 | 11.99 |

| 41 | 60.35 | 59.20 | 60.33 | 11.99 |

| 42 | 63.50 | 65.10 | 70.64 | 11.99 |

| 43 | 63.50 | 65.10 | 70.64 | 11.99 |

| 44 | 63.50 | 65.10 | 70.64 | 11.99 |

| 45 | 63.50 | 65.10 | 70.64 | 11.99 |

| 48 | 66.68 | 66.70 | 70.64 | 11.99 |

| 50 | 69.85 | 71.00 | 70.64 | 13.50 |

| 53 | 76.20 | 73.30 | 70.64 | 13.50 |

| 55 | 79.38 | 78.60 | 70.64 | 13.50 |

| 58 | 79.38 | 82.10 | 70.64 | 13.50 |

| 60 | 79.38 | 82.10 | 70.64 | 13.50 |

| 63 | 82.55 | 84.60 | 70.64 | 13.50 |

| 65 | 92.08 | 88.60 | 69.85 | 15.90 |

| 70 | 95.25 | 90.00 | 69.85 | 15.90 |

| 75 | 101.60 | 102.70 | 73.03 | 15.90 |

| 80 | 114.30 | 104.00 | 79.39 | 19.90 |

| 85 | 117.48 | 108.00 | 79.38 | 19.90 |

| 90 | 123.83 | 112.00 | 79.38 | 19.90 |

| 95 | 127.00 | 119.00 | 82.55 | 19.90 |

| 100 | 133.35 | 124.00 | 85.73 | 19.90 |

description2