PTFE Bellows Seal for Corrosive Applications Replace John Crane WB2

This externally mounted PTFE bellows seal is specifically engineered for handling extremely corrosive media in demanding industrial environments, which provides reliable containment in chemical processing, pharmaceutical manufacturing, pulp and paper production, and wastewater treatment applications, ensuring extended service life in corrosive environments where conventional seals typically fail.

Product Detail

This seal utilizes a full PTFE bellows assembly that provides exceptional resistance to high concentrations of acids, salts, strong oxidizing and reducing agents, and chemically active organic compounds. The design eliminates metal components from direct media contact in critical areas, preventing corrosion failures common in standard metallic seals. The compact, unbalanced configuration ensures reliable performance in chemical process pumps, agitators, and mixers handling the most challenging corrosive media.

Equivalent Products

Our GW WB2 seal offers direct interchangeability with John Crane Type WB2, providing identical dimensional specifications and performance characteristics. Manufactured under ISO9001-certified quality systems, it delivers equivalent sealing performance with enhanced cost efficiency.

Material and Operating Range

Materials:

• Rotary ring: Filled PTFE, Silicon Carbide

• Stationary ring: 99% Ceramic, Silicon Carbide

• Secondary ring: PTFE

• Spring and Metal Parts: SUS304, SUS316

* Custom material configurations and design modifications are available to meet specific application requirements. Contact our engineering team for tailored solutions.

Operating Range:

• Temperature: -20 ℃~120℃

• Pressure: ≤0.5 MPa

• Speed: ≤10m/s

Mediums:

• Chemical processing fluids

• Concentrated acids and alkalis

• Salt solutions and brines

• Oxidizing and reducing agents

• Pulp and paper stocks

• Water and wastewater streams

• Active organic compounds

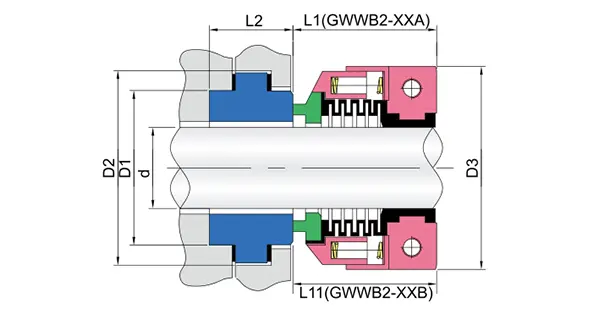

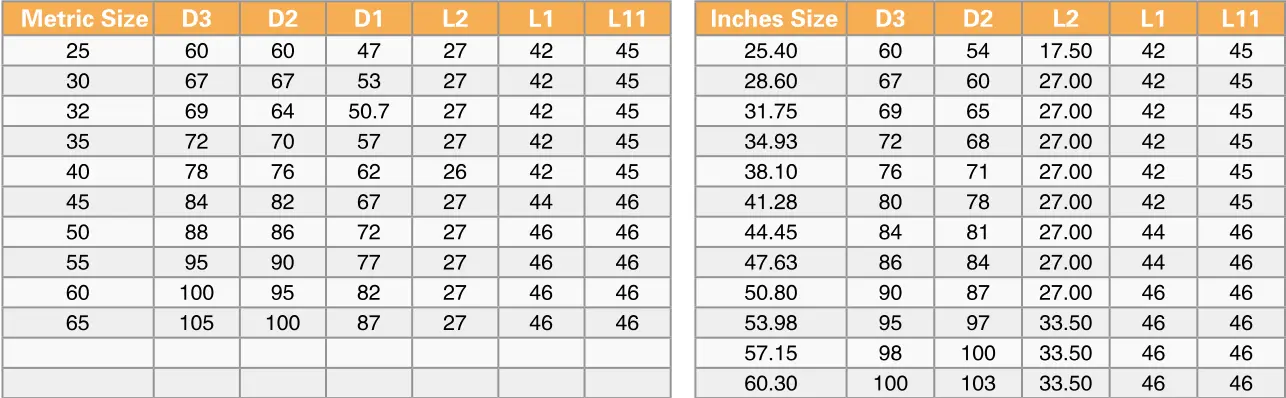

Installation Dimensions

description2