PTFE Bellow Mechanical Seals for Extreme Chemical Service 10T

This advanced mechanical seal solution is specifically engineered to withstand the most challenging chemical environments across multiple industrial sectors:

• Chemical processing industries (handling concentrated acids, aggressive solvents, and strong oxidizers)

• Pulp and paper manufacturing facilities

• Water and wastewater treatment plants

• Pharmaceutical and food processing operations

Product Detail

Validated Equipment Compatibility:

• Chemical process pumps

• Acid transfer and dosing systems

• Corrosive fluid handling equipment

• Agitators and mixers in chemical reactors

Equivalent Products

• AESseal®: Type B08

• Vulcan®: Type 10R

*Cost-effective alternative manufactured under ISO9001 quality standards, offering identical dimensional specifications and equivalent performance characteristics while providing significant savings.

Material and Operating Range

Material Construction:

• Rotary ring: Filled PTFE/ Silicon Carbide (SiC)

• Stationary ring: 99% Ceramic /SiC

• Secondary ring: PTFE

• Metallic components: SUS304/SUS316

*Customization services offered for special material requirements and non-standard dimensional specifications to meet specific application needs.

Operating Envelope:

• Temperature Range: -20 ℃~120℃

• Pressure Limit: ≤1 MPa

• Maximum Surface Speed: 15 m/s (3000 fpm)

• Chemical Resistance: Excellent against most aggressive media

Compatible Media:

• Concentrated acids and alkalis

• Strong oxidizing/reducing agents

• Chemical solvents and reactive organic compounds

• Process water and sewage slurries abrasive content

• Pharmaceutical intermediates

*For specific application requirements or unusual operating conditions, our technical team provides comprehensive support for material selection and seal configuration optimization.

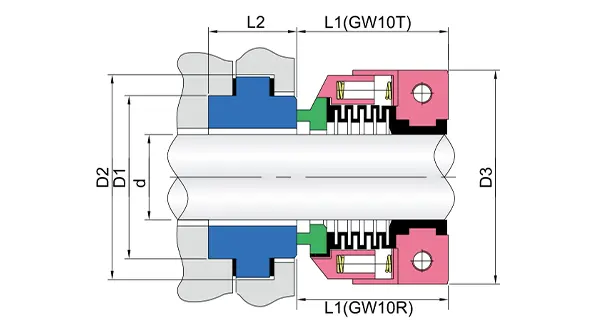

Installation Dimensions

| Size | D3 | D2 | D1 | L2 | L1 |

| 25.40 | 60 | 54 | 42.86 | 17.6 | 33.2 |

| 28.60 | 67 | 65 | 50.80 | 27.0 | 33.2 |

| 31.75 | 69 | 68 | 53.98 | 27.0 | 37.2 |

| 34.93 | 72 | 71 | 57.15 | 27.0 | 38.2 |

| 38.10 | 76 | 78 | 63.50 | 27.0 | 38.2 |

| 41.28 | 80 | 81 | 66.68 | 27.0 | 40.2 |

| 44.45 | 84 | 84 | 69.85 | 27.0 | 40.2 |

| 47.63 | 86 | 87 | 73.03 | 27.0 | 43.2 |

| 50.80 | 90 | 97 | 79.38 | 33.3 | 43.2 |

description2