01

OEM Mechanical Seal GW 160B for APV® W+ Series Pumps

Overview

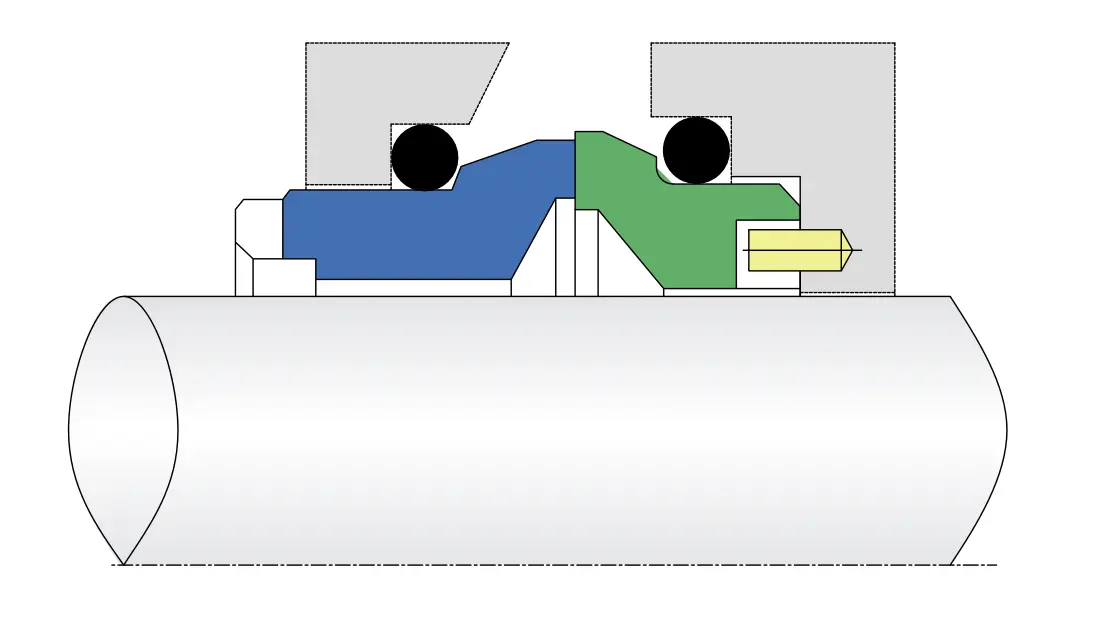

The GW 160B is a specialized OEM mechanical seal engineered as a precise replacement for the original equipment in APV® W+ series pumps. It is designed to meet the exacting standards of sanitary processing, providing a reliable and cost-effective sealing solution for critical fluid transfer operations across multiple industries, especially suitable for food, dairy, and beverage process fluid transfer duties.

Product Detail

+

Specifically configured for hygienic service, the GW 160B delivering stable and leak-free performance in the demanding environment of APV® W+ series pumps. Its optimized face load design ensures minimal wear and extended service life, even under conditions of frequent thermal cycling and pressure fluctuations common in sanitary processing.

Typical Applications

This seal is an ideal direct replacement for APV® W+ series pumps used in:

• Sanitary processing of food, dairy (milk, cream, whey), and beverages (juices, soft drinks).

• Transfer of viscous products, sauces, and ingredients in hygienic manufacturing lines.

• Applications subject to frequent high-temperature Clean-in-Place (CIP) and Steam-in-Place (SIP) sterilization cycles.

Typical Applications

This seal is an ideal direct replacement for APV® W+ series pumps used in:

• Sanitary processing of food, dairy (milk, cream, whey), and beverages (juices, soft drinks).

• Transfer of viscous products, sauces, and ingredients in hygienic manufacturing lines.

• Applications subject to frequent high-temperature Clean-in-Place (CIP) and Steam-in-Place (SIP) sterilization cycles.

Cross-Reference & Compatibility

+

• Compatible Pumps: APV® W+ series sanitary centrifugal pumps.

• Equivalent Models:

o AESseal®: T0WPU

o Sterling®: SWP

o Flowserve (Pac-Seal)®: AWP

• Equivalent Models:

o AESseal®: T0WPU

o Sterling®: SWP

o Flowserve (Pac-Seal)®: AWP

Material and Operating Range

+

Materials & Specifications:

• Rotary Ring: Carbon / Silicon Carbide (SiC)

• Stationary Ring: SIC

• Secondary Seal:VITON /EPDM

• Metallic Components: SUS304 or SUS316 stainless steel

*Note: Consult our technical team for alternative material combinations to suit specific media or extreme operating conditions.

Operating Ranges:

• Temperature: -20°C to +150°C (-4°F to 302°F); temporary peaks possible with selected elastomers

• Pressure: Up to 10 bar (145 psi)

• Speed: Suitable for operation up to 3000 RPM

• Applicable Media: Designed for water, steam, food products, dairy, most beverages, mild cleaning solutions, and similar sanitary process fluids.

• Rotary Ring: Carbon / Silicon Carbide (SiC)

• Stationary Ring: SIC

• Secondary Seal:VITON /EPDM

• Metallic Components: SUS304 or SUS316 stainless steel

*Note: Consult our technical team for alternative material combinations to suit specific media or extreme operating conditions.

Operating Ranges:

• Temperature: -20°C to +150°C (-4°F to 302°F); temporary peaks possible with selected elastomers

• Pressure: Up to 10 bar (145 psi)

• Speed: Suitable for operation up to 3000 RPM

• Applicable Media: Designed for water, steam, food products, dairy, most beverages, mild cleaning solutions, and similar sanitary process fluids.

Installation Dimensions

+

• Standard Seal Sizes: 25 mm, 35 mm, and 55 mm.

• Standard Seal Sizes: 25 mm, 35 mm, and 55 mm.• Detailed installation drawings and instructions are supplied with each unit.

• For requirements involving non-standard dimensions or special configurations, customized solutions are available upon request and quotation.

description2