Your Guide to Troubleshooting Hot Mechanical Seals in Centrifugal Pumps

Hot mechanical seals present a critical challenge for industrial pumps. Their overheating significantly impacts operational reliability. Recognizing the symptoms of these hot mechanical seals quickly prevents costly equipment failure. This guide offers practical, step-by-step solutions for resolution.

Key Takeaways

- Hot mechanical seals cause pump problems. They happen from bad design, wrong setup, or poor care. This makes seals fail fast.

- Look for signs of hot seals. These include cracks on the seal, leaks, or strange noises. You can also check the seal's temperature.

- Fix hot seals by checking pump conditions and the seal's cooling system. Make sure the pump is straight. Pick the right seal and put it in correctly to stop future problems.

Why Your Mechanical Seals Are Overheating

Common Causes of Excessive Heat Generation in Seals

Heat effects are a primary cause of failure in mechanical face seals. Improper design, installation, or maintenance of seals can lead to overheating. This overheating can cause catastrophic failure. Several factors contribute to excessive heat generation. Dry running is a common culprit. It occurs when the seal faces lack proper lubrication. Operating conditions where the seal chamber's pressure exceeds the seal's design parameters also cause overheating. If the process fluid cannot properly lubricate the seal faces, it contributes to heat generation. This lack of lubrication increases friction and heat.

Impact of Overheating on Seal Performance

Overheating significantly reduces the lifespan and effectiveness of mechanical seals. High temperatures cause materials to expand. This expansion affects critical components if it exceeds design tolerances. Seal faces can fracture from sudden cooling of a heated part, known as thermal shock. Cracking due to different thermal expansion rates in materials like tungsten carbide is called heat checking. Elevated temperatures also damage O-rings. They can cause components to loosen or lose their press fit. An enlarged dynamic O-ring can prevent movement, leading to seal face hang-up. Very high temperatures can also cause face warping.

High temperatures increase the chemical reactivity of process media with metal parts, elastomers, and seal faces. Reactivity can double for every 10°C increase. Elastomers lose elasticity and fail to return to their original shape after compression. This leads to leakage. This permanent deformation is called compression set. Thermal aging causes chemical changes, resulting in hardening, cracking, or embrittlement. For seal face materials, inadequate cooling concentrates heat at the faces. This causes thermal stress or lubrication film failure. Excessive heat can evaporate or degrade the lubricating film. This leads to dry contact and increased wear. Temperature fluctuations cause dimensional changes. Rapid temperature changes can induce thermal shock, causing cracking in brittle materials. Understanding these limits helps prevent hot mechanical seals.

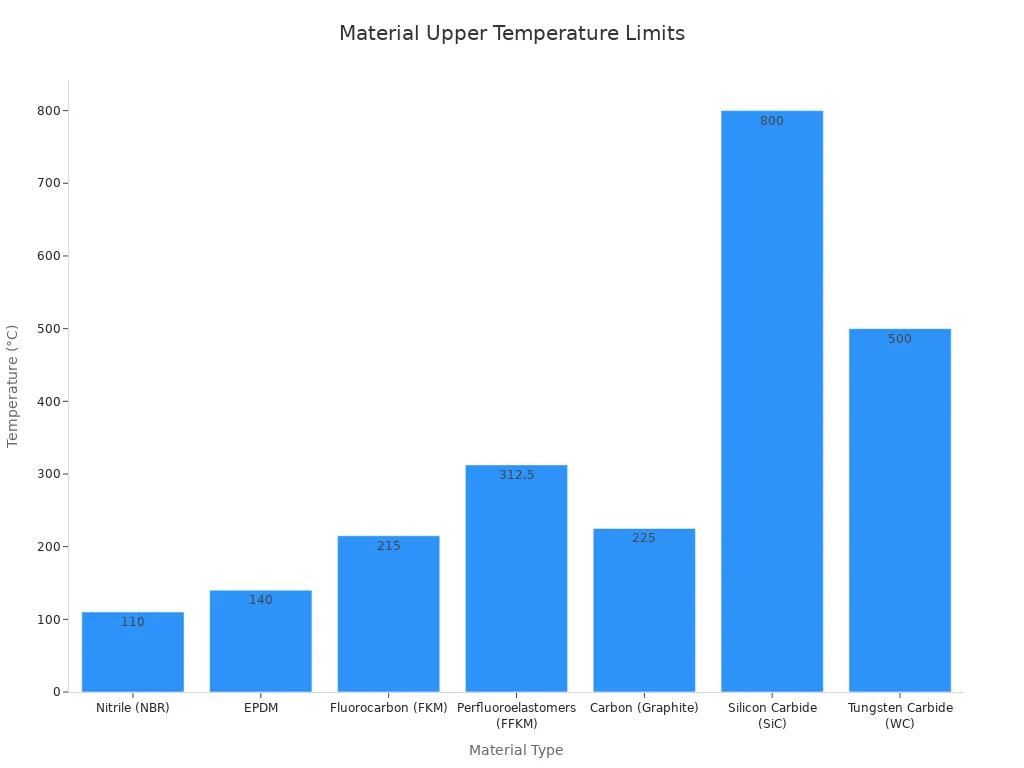

Different materials have specific upper-temperature limits. Exceeding these limits severely compromises seal integrity.

This chart illustrates the maximum operating temperatures for common seal materials.

Identifying Symptoms of Hot Mechanical Seals

Visual Cues of Overheating Seals

Overheating seals often present clear visual indicators. Operators observe fine radial cracks on the seal face, known as heat checking. Friction or temperatures beyond safe operating conditions cause this, leading to excessive stress from mechanical load and thermal expansion. An external visual indication of leakage or vapor may also be present. For hot water pumps, increased steam on the vents can indicate an innermost seal starting to leak. Water or steam coming from the drain also signals an innermost seal leak.

Auditory Indicators of Seal Problems

Auditory cues often signal mechanical seal problems. A sound arising from flashing or face popping indicates an issue. A squealing sound suggests insufficient lubrication for the seal faces. This can result from inadequate liquid or an improperly sized flush line or orifice. A popping sound points to the seal splitting and spluttering, indicating an insufficient liquid environment for the product.

Using Temperature Measurement for Hot Seals

Monitoring seal temperature provides crucial diagnostic information. Different materials and seal types have specific temperature limits. Exceeding these limits compromises seal integrity.

| Material | Temperature Range |

|---|---|

| Carbon Graphite | -200°C to 450°C |

| Silicon Carbide | Up to 1000°C |

| Tungsten Carbide | Up to 600°C |

| Ceramic | Up to 1200°C |

| Seal Type | Temperature Range |

|---|---|

| Single Mechanical Seals | -20°C to 200°C |

| Double Mechanical Seals | -20°C to 300°C |

| Cartridge Mechanical Seals | -20°C to 250°C |

| Seal Type | Temperature Range |

|---|---|

| Metal Bellows Seals | Up to 425°C (797°F) |

| Graphite Seals | Above 600°C (1112°F) |

| Silicon Carbide Seals | Up to 400°C (752°F) |

| Elastomeric Seals | Up to -40°C (-40°F) |

| PTFE Seals (Teflon Seals) | As low as -200°C (-328°F) |

| Metal Bellows Cryogenic Seals | Low temperatures (cryogenic) |

| These tables illustrate the maximum operating temperatures for common seal materials and types. Understanding these ranges helps identify when hot mechanical seals operate outside their safe parameters. |

Step-by-Step Troubleshooting for Hot Mechanical Seals

Troubleshooting hot mechanical seals requires a systematic approach. Each step helps pinpoint the root cause of overheating. Following these steps ensures a thorough investigation and effective resolution.

Step 1: Verify Process Conditions for Your Pump

Begin troubleshooting by examining the pump's operating environment. Process conditions directly influence seal performance.

"The first question I always ask...is: Have there been changes in process conditions that could impact the reliability of the mechanical seal and seal support system?"

This expert advice highlights the importance of initial checks. Look for any recent alterations in the system. Specific process parameters to check for changes include:

- Higher temperature process fluids

- Increased upstream pressure

- Decreased upstream pressure

- Increased particulates in the process fluid

- Transitioning from sweet crude to a sour crude with higher H2S concentrations

These changes can significantly affect the seal's thermal load and lubrication.

Step 2: Inspect the Seal Flush and Quench System

The seal flush and quench system plays a vital role in cooling and lubricating mechanical seals. A malfunctioning system often leads to overheating.

| Symptom | Possible Causes (leading to overheating) |

|---|---|

| Increased upstream fluid temperature | Failure or malfunction of another system component; obstructions in cooling lines |

| Scratches or scoring on the seal faces | Abrasive fluid; inadequate lubrication; incorrect operation of the flush system; low flush flow rate |

| Heat damage to pump components | Inadequate lubrication; incorrect operation of the flush system; low flush flow rate |

| Sputtering or popping | Fluid evaporating at the seal interface; incorrect operation of the flush system; low flush flow rate |

| Squealing | Inadequate lubrication; incorrect operation of the flush system; low flush flow rate |

| Carbon dust accumulation | Inadequate lubrication; fluid evaporating at the seal interface; incorrect operation of the flush system; low flush flow rate |

| Short seal life | Abrasive fluid; seal running hot; obstructions in cooling lines; incorrect operation of the flush system; low flush flow rate |

Inadequate lubrication through the seal fluid or flush system can lead to dry running and overheating of seal faces. Dry running, caused by insufficient liquid in the seal chamber, results in overheating and wear. High temperature issues are often linked to dry running and insufficient lubrication. This highlights the need for adequate liquid in the seal chamber and proper flush system operation. Proper flush plans, such as API piping plans, are essential for ensuring cooling and lubrication. This prevents overheating.

To properly inspect the flush system, consider these best practices:

- Implement proper API piping plans (e.g., Plan 11, Plan 52) for cooling, lubrication, and contamination control.

- Maintain buffer and barrier fluids by checking monthly for changes in color, viscosity, and the presence of solids.

- Change barrier and buffer fluids regularly. Frequency depends on temperature; fluids at higher temperatures need more frequent changes.

- Consider API 682 guidelines for allowable temperature rise in buffer/barrier fluid systems.

- Ensure appropriate piping with short runs, minimal bends, and fittings.

- Use pipe or tubing no smaller than half an inch in diameter; three-quarters of an inch is preferable.

- Select reservoirs considering volume, gas entrainment, and cooling.

- Implement alarm systems for low and high levels, pressures, and temperatures.

- Ensure proper venting to prevent issues and allow fluid circulation by the pumping ring.

- Verify flush flow: Ensure adequate flush for lubrication and cooling of seal faces. Restricted or absent flush flow is a common cause of premature seal failure.

- Maintain clean and functional flush systems to ensure adequate lubrication.

When evacuating a tank, consider using a flush seal system to reduce dry run time and maintain seal lubrication. Ensure cooling systems function optimally to prevent overheating if your seal requires them.

Step 3: Examine the Seal Chamber Environment

The seal chamber's pressure and temperature directly impact seal performance and longevity. These two factors are closely linked and influence each other. Early vaporization can occur when seal chamber pressure is lower than designed. The ability to achieve optimal fluid vaporization between seal faces depends on the pressure of the seal fluid in the seal chamber and the temperature of the seal fluid entering the seal chamber.

API 682 guidelines suggest achieving a sufficient vapor pressure margin by either increasing the seal chamber pressure or decreasing the seal chamber fluid temperature. If the temperature exceeds 140°F (60°C), an internal circulating device and an API Plan 23 closed-loop cooling system are recommended. Malfunctions in the flush system can cause variations in seal chamber pressures and temperatures. Changes in pump flow due to process variations can lead to hydraulic disturbances. These disturbances alter the pumped fluid's pressure and/or temperature. Most mechanical seal applications use the pumped fluid in the seal chamber. Therefore, these changes directly impact the seal chamber pressure and/or temperature. This consequently affects mechanical seal life and reliability. Seal chamber pressure is a crucial parameter to monitor. Its changes can directly influence the seal's operating temperature and overall performance.

Step 4: Evaluate Pump Alignment and Vibration

Poor pump alignment and excessive vibration generate significant heat. Misalignment creates uneven loads on the seal faces. This leads to localized hot spots and accelerated wear. Vibration can cause the seal faces to separate and re-contact rapidly. This action generates friction and heat. Check the pump-motor alignment using precision tools. Monitor vibration levels with appropriate sensors. Correcting alignment issues and reducing vibration can significantly lower seal operating temperatures.

Step 5: Inspect the Mechanical Seal Itself

After checking external factors, inspect the mechanical seal for signs of damage. Visual cues often indicate overheating. An uneven wear pattern on the seal face can be a visual sign of damage caused by elevated temperatures. Chipping on the inside and/or outside edges of the seal faces can result from fluid vaporization across the faces due to high temperatures. This causes repeated hard contacts. Look for:

- Visible cracking or chips on the seal face due to heat shock of ceramic.

- Hardened, brittle, or discolored O-rings, along with compression set, indicating heat damage to elastomers.

- A blue or gold tint color on the seal face, which is a direct indicator of overheating.

These signs confirm that the seal has experienced excessive temperatures. This inspection helps confirm the diagnosis and guides replacement decisions.

Preventing Future Hot Mechanical Seals

Regular Monitoring and Maintenance Schedules

Regular monitoring and maintenance schedules prevent future seal failures. Regularly inspecting mechanical seals and monitoring failure factors extends their lifespan. This ensures operational efficiency and safety. Scheduled inspections lead to prolonged seal life, improved performance, enhanced safety, and reduced pump maintenance costs. Experienced and trained professionals perform proper inspections. They identify potential issues before escalation.

Proper Seal Selection for Your Application

Selecting the correct mechanical seal for an application is paramount. Consider several key factors, especially in high-temperature environments. Operating temperature is critical; the seal must withstand the required heat range. Material compatibility ensures resistance to thermal expansion and chemical corrosion. Seal design, such as metal bellows, cartridge, or dry gas seals, depends on the specific application. Some seals require external cooling or lubrication for effective operation. Industry standards compliance, like API 682, ISO, or DIN, is essential.

| Factor | Metal-to-Metal Seals | Elastomeric Seals |

|---|---|---|

| Temperature Range | Preferred for sustained high temperatures beyond elastomeric limits | Suitable for lower temperatures |

| Pressure | Offers strength and durability for high-pressure applications | Suitable for lower-pressure environments |

| Chemical Compatibility | Necessary for aggressive chemicals | Can be used with less aggressive media and for food-grade compliance |

| Flexibility & Resilience | Less flexible | Chosen for applications requiring flexibility and recovery, such as dynamic systems with movement or temperature cycling |

This table highlights material choices. Metal-to-metal seals suit high temperatures and pressures. Elastomeric seals offer flexibility for lower temperature applications.

Importance of Correct Installation Procedures

Correct installation procedures directly impact a mechanical seal's longevity and performance. Even the best-selected seal fails prematurely if installed incorrectly. Technicians follow manufacturer guidelines precisely. Proper alignment, correct torque settings, and careful handling prevent damage during installation. An improperly installed seal experiences immediate stress. This leads to friction and heat generation. This often results in premature failure, including the development of hot mechanical seals. Investing time in thorough training for installation personnel pays dividends. It extends seal life and reduces downtime.

Systematic troubleshooting effectively prevents pump failure. It identifies root causes quickly. Implementing robust preventive measures ensures reliable pump operation. This proactive maintenance approach significantly extends the lifespan of centrifugal pumps. It also mitigates issues like hot mechanical seals.

FAQ

What causes mechanical seals to overheat?

Dry running, improper lubrication, and operating conditions exceeding design parameters cause overheating. These factors increase friction and heat generation.

How can one identify an overheating mechanical seal?

Visual cues include heat checking and leakage. Auditory signs include squealing or popping. Temperature measurement also confirms overheating.

What is the first step in troubleshooting a hot mechanical seal?

First, verify process conditions for the pump. Check for changes in fluid temperature, pressure, or particulate content.