Unlock Longer Mechanical Seal Life 7 Strategies for Less Downtime and Cost

Unexpected operational interruptions and high maintenance costs often result from premature mechanical seal failures. Discover seven practical strategies to significantly extend the lifespan of your Mechanical Seal. These methods lead to less downtime and substantial cost savings for your operations. Partnering with a reliable mechanical seal supplier is crucial for long-term success.

Key Takeaways

- Mechanical seal failures cause big problems. They stop machines and cost a lot of money.

- You can make mechanical seals last longer. Use seven simple steps to do this.

- Longer seal life means less machine downtime. It also saves your business money.

The Critical Role of Mechanical Seal Reliability

Understanding Mechanical Seal Failure Impact

Mechanical seal failures significantly disrupt industrial operations. When a seal fails, it often leads to immediate equipment shutdown, halting production. For example, a North Sea rig experienced a $2 million loss in 2023 due to a seal-related shutdown. Another team faced a $500,000 financial impact from a single mechanical seal incident. A rig supervisor also incurred $200,000 monthly in downtime costs because of leaking pumps. These incidents highlight the severe financial consequences that stem directly from seal malfunctions.

Unveiling Hidden Costs of Downtime

The costs associated with mechanical seal failures extend far beyond immediate repair expenses. Unscheduled downtime brings operations to a halt, leading to lost production time and idle labor. This also causes customer dissatisfaction. A single hour of downtime in manufacturing can cost thousands of dollars. Furthermore, waiting for a component to fail often results in more expensive repairs or full replacements. Minor issues, if not addressed early, can escalate into significant damage requiring complete overhauls. Poorly maintained equipment also consumes more energy, increasing utility bills. Equipment failures, especially with hazardous materials, endanger workers and the environment, leading to injuries, lawsuits, and regulatory fines. A single equipment failure can also cause delays, spoilage, and contractual penalties throughout the supply chain. Low-quality seals deteriorate faster, leading to lost revenue and increased emergency maintenance. This also causes product contamination, potentially ruining entire batches. In regulated industries, seal failures can lead to serious compliance issues, including product recalls and substantial regulatory fines.

Strategy 1: Precision Mechanical Seal Installation

Precision in mechanical seal installation directly influences its operational lifespan. Proper installation minimizes wear and prevents premature failure, ensuring optimal performance.

Mastering Proper Alignment Procedures

Achieving precision assembly and running conditions is paramount. Mechanical seal faces require high-precision manufacturing and environments. For optimal running, motor and pump centerline alignment must be perfect, within 0.050 mm (0.002”) at operating temperature for 4-pole motor speeds. Eliminating vibration caused by poor balance or installation is crucial. Operators must ensure seal faces remain square to the shaft. Shaft deflection at the seal face should not exceed 0.025-mm (0.001”).

Before installation, inspect equipment for damage. Ensure the sealing area is clean. Install the cartridge seal according to manufacturer specifications, ensuring proper alignment. Deviations from recommended dimensions lead to misalignment. For example, seal face parallelism typically requires a maximum deviation of 0.002" - 0.005". Poor tolerance control can cause actual assembly deviations of 0.010" - 0.025". This results in one-sided face contact and rapid wear. Precision alignment techniques, using tools like dial indicators or laser alignment, are essential during assembly.

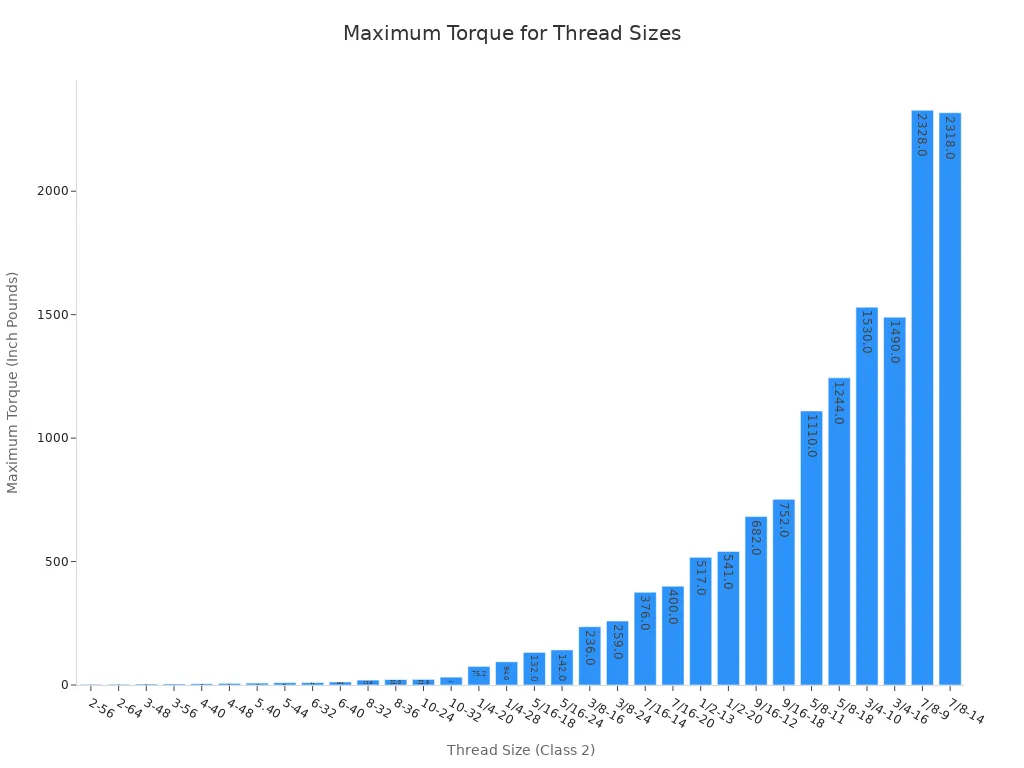

Adhering to Correct Torque Specifications

Correct torque application is vital for proper sealing and component integrity. Fasteners should be tightened to the torque specifications provided by the equipment manufacturer. A torque wrench is necessary to ensure correct tightening of all bolts and fasteners. Over-tightening deforms components. Under-tightening leads to leaks. The following table provides maximum torque specifications for various thread sizes in inch-pounds for 18-8 Stainless Steel fasteners with dry, non-lubricated threads.

| Thread Size (Class 2) | Maximum Torque (Inch Pounds) |

|---|---|

| 2-56 | 2.5 |

| 2-64 | 3.0 |

| 3-48 | 3.9 |

| 3-56 | 4.4 |

| 4-40 | 5.2 |

| 4-48 | 6.6 |

| 5.40 | 7.7 |

| 5-44 | 9.4 |

| 6-32 | 9.6 |

| 6-40 | 12.1 |

| 8-32 | 19.8 |

| 8-36 | 22.0 |

| 10-24 | 22.8 |

| 10-32 | 31.7 |

| 1/4-20 | 75.2 |

| 1/4-28 | 94.0 |

| 5/16-18 | 132.0 |

| 5/16-24 | 142.0 |

| 3/8-16 | 236.0 |

| 3/8-24 | 259.0 |

| 7/16-14 | 376.0 |

| 7/16-20 | 400.0 |

| 1/2-13 | 517.0 |

| 1/2-20 | 541.0 |

| 9/16-12 | 682.0 |

| 9/16-18 | 752.0 |

| 5/8-11 | 1110.0 |

| 5/8-18 | 1244.0 |

| 3/4-10 | 1530.0 |

| 3/4-16 | 1490.0 |

| 7/8-9 | 2328.0 |

| 7/8-14 | 2318.0 |

Strategy 2: Optimal Mechanical Seal Material Selection

Selecting the correct materials for a Mechanical Seal is crucial for its longevity and performance. The right material choice prevents premature failure and ensures operational reliability.

Matching Materials to Fluid Properties

The fluid's properties directly determine the required seal material characteristics. Incompatible materials lead to rapid wear or failure. Seal materials must withstand the fluid being processed and be chemically compatible to prevent seal failure. Abrasive liquids cause excessive wear, shortening seal life. Therefore, materials should possess good wear resistance. Materials must also resist corrosion, especially when dealing with aggressive fluids. For corrosive chemical environments, material compatibility, temperature resistance, and long-term durability are critical. Abrasive wear is a significant challenge, particularly when fluids contain suspended solids. Harder materials like tungsten carbide and silicon carbide offer superior wear resistance. However, their brittle nature requires careful consideration of abrasive particle size to prevent chipping.

For aggressive chemical applications, specific material combinations prove effective. FFKM (Perfluoroelastomer) offers near-universal chemical resistance to strong acids, bases, and solvents. PTFE (Polytetrafluoroethylene) is chemically inert to almost all chemicals, making it highly resilient. EPDM (Ethylene Propylene Diene Monomer) provides excellent resistance to water, steam, and many acids. For seal faces, nickel-bound tungsten carbide grades are recommended. Elastomers like FFKM, FKM, PTFE, and EPDM are highlighted for their chemical resistance. Metal components often use 316 Stainless Steel for aggressive chemicals, with Hastelloy® or Monel® available for more demanding needs.

Considering Temperature and Pressure Extremes

Extreme operating temperatures and pressures significantly influence material degradation rates. Temperature fluctuations cause seal materials to expand and contract. Expansion leads to excessive wear, while contraction creates gaps and leaks. Repeated thermal cycling stresses materials, potentially causing cracks or deformation. High temperatures accelerate the chemical and physical breakdown of seal materials. For elastomers, elevated temperatures break down molecular bonds, leading to hardening or cracking. Compression set, a material's inability to return to its original shape after prolonged compression, is also a concern, especially under high temperatures. Once a seal takes a compression set, it loses proper contact, resulting in leaks.

Strategy 3: Effective System Design for Mechanical Seals

An effective system design directly impacts the longevity and performance of a Mechanical Seal. Proper design prevents common failure modes and ensures stable operation.

Ensuring Adequate Flushing and Cooling

Proper flushing and cooling are essential for maintaining seal integrity. Flushing removes heat and abrasive particles from the seal faces. For external flush systems, a flushing liquid pressure of about 10-15 psi above the pump seal chamber pressure is usually enough. Typical flow rates for external flush are around 0.25-0.50 gpm. For API Plan 32 seal isolation, increasing the flush until the seal chamber pressure rises by at least 10 psi is recommended. Increases up to 25 psi above the seal chamber pressure are common. Another method for API Plan 32 suggests a flush flow rate of 1 gpm for each inch of seal diameter for pumps running at 3600 rpm. High-speed seals with textured side-walls benefit from a flush flow of approximately 15 L/min for effective cooling. Considering both heat dissipation and transfer, a flush flow of 15–20 L/min is ideal for these seals.

Implementing Vibration Reduction Measures

Vibration is a major cause of premature seal failure. System design must include measures to minimize it. Ensure proper alignment of rotating equipment. This reduces stress on the seal components. Balancing rotating parts also prevents excessive vibration. The system should incorporate stable mounting for all components. This includes the primary sealing elements, secondary sealing elements, and adaptive hardware like end plates. These components must be securely fixed to prevent movement that could induce vibration. A well-designed system minimizes shaft deflection and ensures smooth operation, extending seal life.

Strategy 4: Proactive Mechanical Seal Maintenance Practices

Proactive maintenance significantly extends the operational life of a Mechanical Seal. It prevents unexpected failures and reduces overall costs.

Establishing Regular Inspection Schedules

Regular inspections are crucial for early detection of potential issues. Conduct visual checks for any signs of wear, leaks, or damage. Examine the seal face condition for scoring or pitting. These routine checks help identify problems before they escalate. Operators must prevent seals from running dry. Dry running causes heat buildup and can lead to catastrophic failure. Consider installing a dry-run monitor for critical applications. Also, avoid excessive vibration in pump systems. Operate pumps within their Best Efficiency Point (BEP). This prevents recirculation and cavitation, which cause damaging vibration. Address any system degradation or imbalance promptly.

Timely Component Replacement Protocols

Timely replacement of components based on inspection findings or predetermined schedules is essential. Always ensure correct lubrication. A proper cooling fluid film between seal faces minimizes wear and friction. Incorrect lubricants can increase temperatures and cause damage. Adhere to proper installation guidelines even during maintenance. Misaligned or geometrically imperfect installations lead to seal failure. Choose seals specifically designed for operating conditions. Ensure material compatibility with fluids and environments. Track performance indicators like leakage rates and temperature. Adjust operating parameters to prevent excessive wear. Implement contamination control strategies. Maintain a clean environment and use filtration systems to remove particulates from the fluid. For applications with fluids like dextrose or sucrose, a flush seal may be necessary. This rinses the seal with water, preventing sugar buildup that can cause leaks.

Strategy 5: Advanced Mechanical Seal Monitoring Solutions

Advanced monitoring solutions significantly enhance the reliability and lifespan of a Mechanical Seal. These technologies provide crucial insights into operational health, preventing unexpected failures.

Leveraging Real-time Performance Tracking

Real-time performance tracking offers continuous oversight of seal conditions. Sensor-enabled seals provide immediate data, which is vital for preventing unexpected failures and supporting predictive maintenance strategies. A comprehensive preventive monitoring system continuously tracks the condition of mechanical seals. This system identifies thresholds for undesirable pressure changes. It then operationalizes these findings into a live monitor. A real-time dashboard alerts teams to anomalies like unexpected pressure changes. This enables timely interventions and proactive maintenance scheduling. Such monitoring allows for regular inspection and monitoring to detect early signs of wear, preventing unexpected failures. It also provides valuable insights into seal health through routine inspection for leaks, changes in vibration, or excessive heat buildup.

Utilizing Predictive Analytics for Wear Detection

Predictive analytics moves beyond simple condition monitoring by forecasting future failures. Predictive Maintenance (PdM) predicts the probability and timeframe of a catastrophic failure. It combines data such as rising vibration, temperature, and power efficiency drops. Smart mechanical seals with integrated IoT sensors monitor real-time performance data like pressure, temperature, and leakage. Sophisticated algorithms analyze these data patterns. They identify potential issues before they escalate into costly failures. Machine learning algorithms process vast amounts of sensor data. They identify subtle patterns indicative of impending seal degradation or failure. Predictive analytics capabilities forecast maintenance requirements weeks or months in advance. They analyze historical performance data, environmental conditions, and operational parameters. This approach helps detect seal degradation before it leads to significant issues. It uses advanced technologies like vibration analysis, thermal imaging, or smart sensors. This maintains continuous and reliable operation, minimizing system breakdowns caused by overheating or dry-running.

Strategy 6: Operator Training and Mechanical Seal Awareness

Effective operator training significantly enhances the lifespan of a Mechanical Seal. Well-informed operators can prevent failures and optimize system performance.

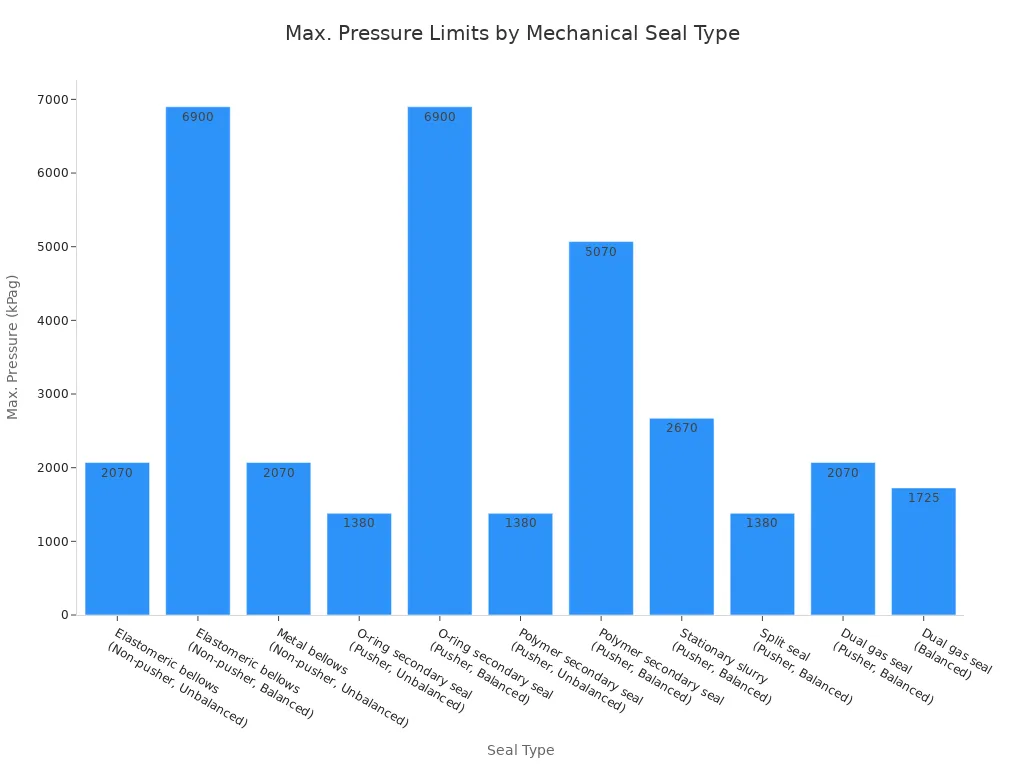

Understanding Seal Operation Limits

Operators must understand the specific operational limits for various seal types. These limits define safe operating conditions. Published mechanical seal application limits typically involve pressure, speed, and temperature. Operators should know these limits for steady-state operation. However, transient conditions like pressure spikes or vibration often require expert advice. Applications become more challenging with larger shaft diameters, faster speeds, higher temperatures, increased pressure, or greater solids content.

| Seal Type | Max. Pressure (kPag/psig) | Temperature Range (ºC / ºF) |

|---|---|---|

| Elastomeric bellows (Non-pusher, Unbalanced) | 2070 / 300 | -40 to 205 / -40 to 400 |

| Elastomeric bellows (Non-pusher, Balanced) | 6900 / 1000 | -40 to 205 / -40 to 400 |

| Metal bellows (Non-pusher, Unbalanced) | 2070 / 300 | -75 to 425 / -100 to 800 |

| O-ring secondary seal (Pusher, Unbalanced) | 1380 / 200 | -40 to 260 / -40 to 500 |

| O-ring secondary seal (Pusher, Balanced) | 6900 / 1000 | -40 to 260 / -40 to 500 |

| Polymer secondary seal (Pusher, Unbalanced) | 1380 / 200 | -75 to 260 / -100 to 500 |

| Polymer secondary seal (Pusher, Balanced) | 5070 / 500 | -75 to 260 / -100 to 500 |

| Stationary slurry (Pusher, Balanced) | 2670 / 400 | -40 to 205 / -40 to 400 |

| Split seal (Pusher, Balanced) | 1380 / 200 | -40 to 205 / -40 to 400 |

| Dual gas seal (Pusher, Balanced) | 2070 / 300 | -40 to 260 / -40 to 500 |

| Dual gas seal (Balanced) | 1725 / 250 | -40 to 260 / -40 to 500 |

Recognizing Early Warning Signs of Failure

Operators need training to identify early warning signs of seal failure. This allows for timely intervention. Educational programs on pumping and seal systems are crucial. These programs cover:

- Proper selection of mechanical seals.

- Correct installation procedures.

- Systematic maintenance practices.

- Prompt diagnostic response to operational changes.

Visual signs of mechanical seal failure include:

- Grooves or notches on the seal face.

- Uneven wear tracks.

- Fractured or cracked seal faces.

- Chipped seal rings.

- Accumulation of carbon dust on the outside of the seal.

Auditory signs of mechanical seal failure include:

- Squealing sounds during operation.

- Popping sounds during operation.

Training resources like web-based tools for failure analysis and pump simulators provide virtual hands-on experience. This helps operators learn safe startup, failure causes, and the effects of operating parameters. Investing in proper training significantly reduces failures and improves reliability.

Strategy 7: Maintaining Fluid Quality for Mechanical Seals

Maintaining optimal fluid quality directly impacts the longevity and efficiency of a Mechanical Seal. Contaminated or improperly lubricated fluids accelerate wear and lead to premature failure.

Implementing Contaminant Control Strategies

Effective contaminant control is crucial for protecting mechanical seals. Mechanical seals prevent external contaminants like oils, sediments, and other adulterants from entering process fluids. This maintains fluid integrity and quality control standards. To achieve this, implement several key strategies. Always start with clean, new oil that meets OEM specifications. This prevents harmful particles from entering the system from the beginning. Regularly monitor oil cleanliness using methods like patch testing to assign an ISO Cleanliness Code. Routinely replace dust caps on lubrication valves and oil filters to reduce contaminants. Use certified oil transfer containers to keep oil clean and dry during transfer. Ensure filtration systems are properly balanced and sized to remove critical clearance-sized particles, ideally with technical expert involvement.

Ensuring Proper Lubrication Management

Proper lubrication management is essential for seal health. Fluid quality parameters directly impact mechanical seal longevity. These include chemical compatibility with seal materials, stability, flow properties at various temperatures, and foaming tendencies. Low gas solubility, good lubricity, and effective heat transfer properties are also important. Consider the maximum operating temperature and allowable temperature rise. Establish a recommended interval between fluid changes based on temperature. Choose the right lubricant, considering viscosity and additives like antioxidants or anti-wear agents. Set up a lubrication schedule following manufacturer instructions, adjusting for high-use or extreme environments. Employ proper lubricant application techniques, avoiding both under-lubrication and over-lubrication. Implement contamination control measures to prevent dirt, water, and metal particles from degrading lubricant quality. Monitor and analyze lubricant conditions through routine oil sampling and thermal imaging. Finally, educate and train maintenance personnel in proper lubrication techniques.

Tangible Benefits of Extended Mechanical Seal Life

Extending the operational life of a Mechanical Seal offers significant advantages. These benefits translate directly into financial gains and improved operational stability for industrial facilities.

Achieving Significant Cost Savings

Longer mechanical seal life directly reduces the Total Cost of Ownership (TCO). This happens by decreasing the need for frequent replacements. Facilities save money on parts, installation labor, and financial losses from operational downtime. Administrative overhead associated with more frequent maintenance schedules also decreases. For example, addressing continuous leakage in condensate recovery pumps can lead to annual fuel savings of $88,000. Total savings can reach $122,000. Eliminating 100 GPM water injection in chemical recovery boiler evaporators can save between $250,000 and $360,000. Energy losses from seal support systems, such as a Plan 32 configuration, can cost $33,293 per year per application.

Extending the Mean Time Between Maintenance (MTBM) from 1.5 years to 5 years significantly reduces inventory needs. Implementing failure prevention and predictive maintenance can cut storeroom inventories by over 50 percent. A facility with 500 pumps can free up $500,000 to $1 million tied up in spare parts. This also reduces annual inventory carrying costs, typically 10 to 25 percent of the total inventory value. Predictive maintenance can lower the average repair cost per pump from $2,500 to $1,500. This leads to substantial annual savings.

| Metric | Original State | Reduced State / Savings |

|---|---|---|

| MTBM (Mean Time Between Maintenance) | 1.5 years | 5 years (significantly reduces inventory) |

| Storeroom Inventory Reduction | N/A | Greater than 50 percent |

| Spare Parts/Pump/Seal Inventory | $500,000 to $1 million (for 500 pumps) | Reduced, freeing up cash |

| Inventory Carrying Costs | 10-25% of total inventory value (annually) | Reduced by lowering inventory |

| Average Maintenance Cost per Pump | $2,500 (catastrophic failures often higher) | Reduced to $1,500 (with predictive maintenance) |

Enhancing Overall Operational Efficiency

Extended mechanical seal life directly improves Overall Equipment Effectiveness (OEE). Industrial facilities using advanced seal technology report substantial improvements in Mean Time Between Failures (MTBF). This directly correlates with lower maintenance costs and enhanced operational efficiency. Seals that maintain consistent performance in demanding conditions lead to fewer production interruptions. This ultimately improves OEE. Reduced seal replacements cut material and labor costs. This reduction in downtime directly increases production capacity. Major refineries report millions of dollars in additional annual revenue due to improved equipment availability. Enhanced reliability, stemming from precision manufacturing and advanced materials, contributes to reduced maintenance costs, lower inventory needs, and improved OEE for refinery operations.

Implement these seven strategies for lasting Mechanical Seal performance. Proper installation, material selection, and fluid quality are critical factors for seal reliability. Regular inspections and condition monitoring are essential reliability best practices. Businesses achieve greater operational reliability and reduce unexpected interruptions. This realizes substantial cost reductions and improves their bottom line.

FAQ

❓ What is the primary benefit of extending mechanical seal life?

Extending mechanical seal life significantly reduces operational downtime and maintenance costs. It also enhances overall equipment efficiency and reliability.

🛠️ How does proper installation impact seal longevity?

Precision installation, including correct alignment and torque, prevents premature wear. It ensures optimal seal performance and extends its operational lifespan.

💧 Why is fluid quality important for mechanical seals?

Maintaining fluid quality prevents contamination and ensures proper lubrication. This protects seal faces from abrasive particles and chemical degradation, extending seal life.