The Cost-Saving Power of Slurry Mechanical Seals in Mining

Mining operations often face significant cash leaks due to equipment failures. The implementation of a slurry mechanical seal, specifically the Flygt Pump Seal, offers a high-speed slurry sealing solution that enhances reliability. This innovation, including alternatives like the AES T05A, has effectively reduced maintenance costs and improved overall operational efficiency.

Core Insights

- Slurry mechanical seals enhance reliability in mining operations, significantly reducing maintenance costs and improving equipment lifespan.

- The robust design of these seals allows for better performance in harsh conditions, leading to lower operating costs and less frequent repairs.

- Comprehensive after-sales support for staff on seal maintenance is crucial for maximizing performance and ensuring efficient operations.

Features of the Slurry Mechanical Seal

Robust and Compact Design

The robust and compact design of the slurry mechanical seal significantly enhances its durability in harsh mining environments. This design effectively manages high solids content and abrasive materials, which are common in mining operations. The GW05A Slurry Cartridge Seal exemplifies this approach. Its non-clog design and advanced pressure plate system prevent operational failures. Additionally, the use of durable materials increases resistance to abrasion and corrosion, ensuring a longer lifespan in aggressive conditions.

Key benefits of the robust design include:

- Built for high-solids and high-pressure conditions

- Enables longer pump run times

- Lowers total operating costs compared to traditional packed glands

- Designed for long-term reliability and reduced lifecycle costs

- Supports water conservation with minimal flush requirements

The compact nature of the slurry mechanical seal facilitates easier integration into existing mining equipment. It reduces installation time and errors, allowing for fitting into various configurations without extensive modifications. This is particularly beneficial in environments with limited space and a need for efficiency.

Metal-to-Metal Sealing Interface

The metal-to-metal sealing interface of slurry mechanical seals offers superior leak prevention compared to traditional sealing technologies. This interface fills misalignments and leak paths through metal flow, ensuring a tight seal even under extreme conditions. In contrast, elastomeric seals may degrade under high pressure and temperature, leading to potential failures.

The effectiveness of the metal-to-metal sealing interface can be summarized in the following table:

| Sealing Method | Advantages | Disadvantages |

|---|---|---|

| Metal-to-metal sealing | - Fills misalignments and leak paths through metal flow | - Limited disassembly and reuse without leaking |

| Elastomeric seals | - Flexible and can accommodate some misalignments | - May degrade under high pressure and temperature |

| Pipe threads | - Simple installation and low cost | - Limited sealing effectiveness under high pressure |

Materials commonly used in the metal-to-metal sealing interface include stainless steel and Inconel. These materials provide excellent corrosion resistance and strength, making them suitable for a wide range of applications. The following table highlights the key properties of these materials:

| Material | Key Properties |

|---|---|

| Stainless Steel | Excellent corrosion resistance and strength, suitable for a wide range of applications |

| Inconel | Superior high-temperature strength and oxidation resistance, ideal for aerospace and chemical processing |

The combination of a robust design and a metal-to-metal sealing interface positions the slurry mechanical seal as a reliable solution for mining operations. It addresses common failure modes of traditional seals, such as wear and unstable process conditions, while improving overall reliability and reducing leakage.

Implementation Process

Installation Steps for Optimal Performance

To ensure optimal performance of the slurry mechanical seal, follow these essential installation steps:

- Install Seal on Shaft: Slide the seal assembly onto the shaft, ensuring correct orientation. Avoid damaging the sealing faces during this process.

- Position Seal: Place the seal within the pump according to the manufacturer's specifications. This often requires setting the seal at a specific depth or alignment relative to the shaft end or casing.

- Reassemble Components: Carefully reassemble other parts of the equipment, such as impellers and bearings. Ensure all components align and seat properly.

- Tighten Fasteners: Secure all bolts and fasteners to the torque specifications provided by the equipment manufacturer.

- Leak Testing: After assembly, perform a leak test according to the manufacturer’s instructions. This may involve running the equipment at a low operational level in a controlled environment.

- Operational Test: Conduct a complete operational test to verify that the seal functions correctly under normal working conditions.

Note: Common challenges during installation include cavitation issues, abrasive wear, and seal leakage. Addressing these challenges proactively can enhance the seal's longevity and performance.

Dedicated Post-Sale Support for Your Operations

To ensure your slurry mechanical seals operate at peak performance long after installation, we provide comprehensive post-sale technical support tailored to the mining industry. Our support services are designed to minimize downtime, extend seal life, and protect your bottom line.

We are here to help with:

- Rapid troubleshooting and remote technical assistance for seal-related issues.

- On-site service support for inspection, maintenance, and failure analysis.

- Seal performance optimization recommendations based on real operating conditions.

- Root cause analysis for unexpected failures, helping prevent future issues.

Your dedicated support options include:

- Direct access to our seal engineering specialists by phone or email.

- Scheduled or emergency on-site assistance.

- Detailed analytical reporting and follow-up to ensure issue resolution.

Through responsive and cost-effective support, we help you maintain operational continuity and maximize the return on your sealing solution investment.

Results Achieved

Improved Reliability and Lower Labor Costs

The introduction of slurry mechanical seals has led to remarkable improvements in equipment reliability. Mining operations that faced challenges with traditional sealing methods have reported significant enhancements. For instance, one mining operation modified standard centrifugal pumps to handle highly abrasive slurry. They utilized wear-resistant materials and adjusted the internal geometry to reduce turbulence. As a result, these modified pumps exhibited a substantial increase in service life and a decrease in maintenance needs. This shift not only improved operational efficiency but also reduced labor costs associated with frequent repairs.

The benefits of improved reliability can be summarized as follows:

- Extended Equipment Lifespan: Enhanced durability leads to longer intervals between replacements.

- Reduced Maintenance Frequency: Operators experience up to four times fewer maintenance interventions compared to traditional packing methods.

- Lower Labor Costs: With fewer repairs needed, labor expenses decrease significantly.

Significant Cost Reductions

Implementing slurry mechanical seals has proven to be a cost-effective solution for mining operations. The transition from traditional sealing methods to mechanical seals has resulted in substantial financial savings. For example, the RAP-SS mix required 19% less asphalt binder than the virgin SS mix, leading to a total cost reduction of 14% compared to conventional methods.

The following table illustrates the various ways slurry mechanical seals contribute to cost reductions:

| Benefit | Description |

|---|---|

| Robust Design | Supports intermittent operations, reducing wear and tear. |

| Longer Pump Run Times | Lower operating costs compared to pumps with packed glands. |

| Engineered for Reliability | Sustainability and reduced cost of ownership. |

| Water Savings | Ability to operate with reduced or no flush, conserving resources. |

By eliminating daily and weekly maintenance schedules on tailing lines, operators can achieve uninterrupted operation for extended periods. This leads to significant maintenance cost savings and reduced equipment downtime.

Increased Production Efficiency

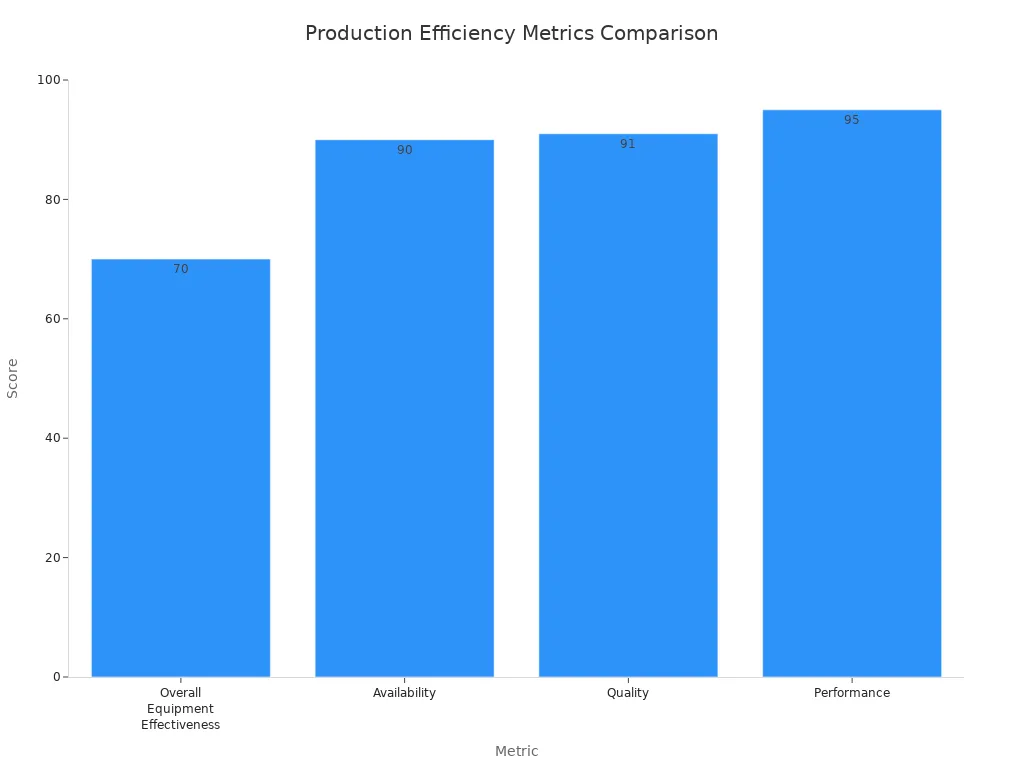

The implementation of slurry mechanical seals has also resulted in increased production efficiency. Metrics such as Overall Equipment Effectiveness (OEE) demonstrate this improvement. After installing slurry mechanical seals, one mining operation reported a 12% increase in OEE, indicating higher productivity and better returns on investment.

The following table highlights key metrics before and after the implementation of slurry mechanical seals:

| Metric | Score | Change | Benefit |

|---|---|---|---|

| Overall Equipment Effectiveness (OEE) | 70 | +12% | Improved OEE leads to higher productivity and better return on investment. |

| Availability | 90 | -2% | Understanding availability helps minimize downtime, ensuring continuous operations. |

| Quality | 91 | -1% | Maintaining high-quality standards reduces waste and enhances overall product quality. |

| Performance | 95 | +3% | Higher performance scores indicate more efficient operations, leading to energy savings. |

Slurry mechanical seals deliver significant advantages for mining operations. They enhance reliability, reduce maintenance costs, and improve production efficiency. By minimizing leaks and downtime, these seals contribute to substantial cost savings. Overall, they play a crucial role in optimizing mining processes and ensuring sustainable operations.

FAQ

What are the main benefits of using slurry mechanical seals in mining?

Slurry mechanical seals improve reliability, reduce maintenance costs, and enhance production efficiency in mining operations.

How do slurry mechanical seals differ from traditional sealing methods?

Slurry mechanical seals utilize a metal-to-metal sealing interface, offering superior leak prevention compared to elastomeric seals.