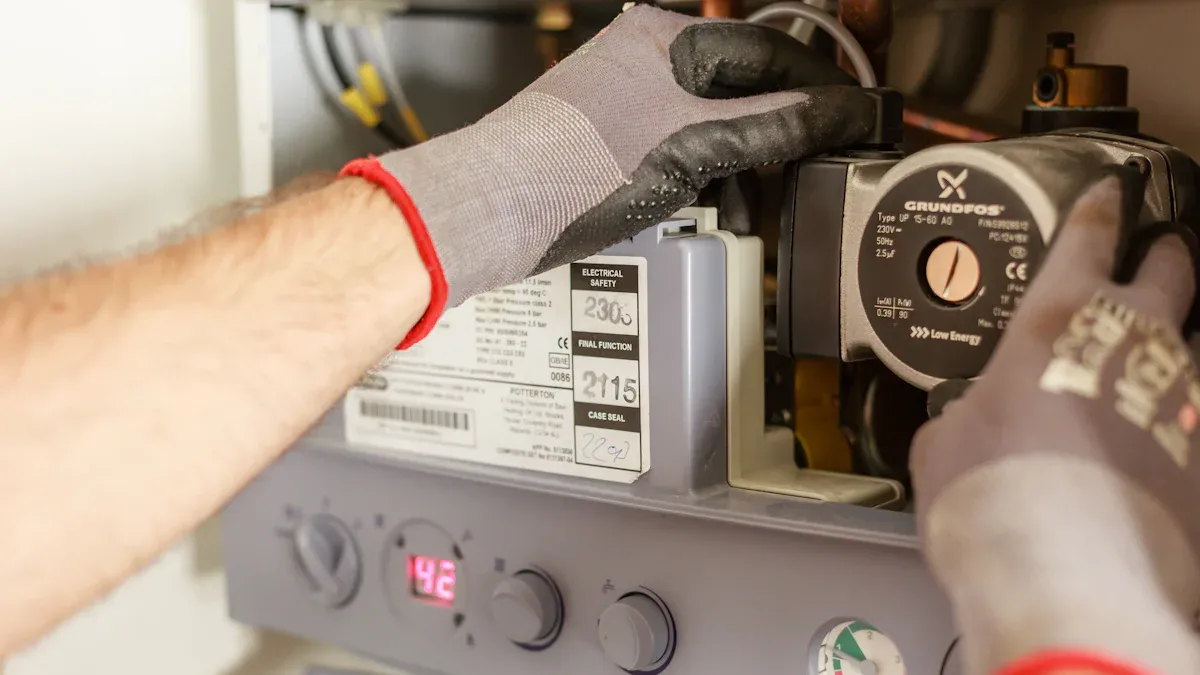

Stop Grundfos Seal Leaks Proven Strategies for Chemical Plants

Chemical plants face critical challenges from Grundfos pump seal failures. These failures severely impact safety and operational continuity. Mechanical seal failures cause approximately 40% of all unscheduled critical pump shutdowns. They represent the second most common pump issue, accounting for 20–25% of all failures. Effective strategies are urgently needed to prevent costly downtime and environmental risks associated with a leaking grundfos pump seal.

Key Takeaways

- Choose the right seal materials for chemicals. This stops early wear and leaks.

- Install seals correctly. Follow all steps to prevent damage and ensure long life.

- Use smart tools to watch seals. This helps fix problems before they cause big leaks.

Uncovering Root Causes of Grundfos Pump Seal Failures in Chemical Plants

Understanding why Grundfos pump seals fail is the first step toward preventing costly leaks and operational disruptions. Several factors contribute to these failures in chemical plants, ranging from initial selection errors to ongoing operational and maintenance issues. Identifying these root causes allows plants to implement targeted and effective preventative measures.

Inadequate Grundfos Pump Seal Selection for Corrosive Media

Chemical plants routinely handle aggressive and corrosive fluids. The materials used in a pump seal must withstand these harsh substances. Pump systems handling corrosive fluids or chemicals are highly susceptible to seal failures. Corrosion and chemical attack can erode seals and compromise their integrity. Choosing the wrong seal for an application leads to premature wear, inadequate sealing, and eventual failure. This highlights the importance of considering the fluid being pumped. To prevent seal failures in such environments, it is crucial to select seals specifically designed to withstand the substances present. This often requires resistant materials like specialized elastomers. Improper seal material selection is a common cause of Grundfos pump seal issues.

Operational Stress and Process Instability Leading to Seal Wear

Pump seals operate under various conditions, and certain operational stresses significantly accelerate wear. Dry running is a major culprit. When a pump operates without product passing through it, the lack of lubrication causes increased friction and wear. This results in the premature failure of vital parts like seals. The absence of lubrication from fluids leads to excessive friction on the seal faces, causing overheating and accelerated wear. Mechanical seals rely on the pumped fluid for lubrication and cooling. Without this crucial lubricating film, rapid friction and extreme heat effectively burn and destroy the seal faces.

Frequent start-stop cycles also contribute to seal degradation. These cycles lead to thermal cycling and increased mechanical stress. This, in turn, accelerates the wear rate of Grundfos pump seals. Such intermittent duty cycles necessitate seal designs specifically optimized for these demanding applications.

Improper Installation and Commissioning of Grundfos Pump Seals

Even the highest quality pump seal will fail prematurely if installed incorrectly. Mechanical seals are delicate components requiring precise handling and adherence to manufacturer guidelines. Common installation errors lead to immediate or early leaks. These errors include incorrect seal selection, misalignment, or improper torque during assembly. Symptoms often include leakage, difficulty achieving desired pressure, and unusual noises or vibrations.

Shaft misalignment between the pump shaft and seal causes uneven wear and premature failure. This can result from improper installation, foundation settling, or pipe strain. Not following installation guidelines, such as removing spacers or correctly using cartridge seals, also contributes to problems. Inadequate seal care, like insufficient lubrication or unhygienic conditions (e.g., dirt or fingerprints), compromises the seal face. Over-tightened fasteners can distort seal components, causing leaks. Attempting to tighten further when a leak occurs only worsens the problem.

Proper installation involves several critical steps. These include pre-installation inspection and preparation, such as examining the pump shaft for alignment and cleaning the seal chamber. Proper installation techniques involve carefully removing old components, cleaning mating surfaces, and applying compatible lubricants. Installers must position stationary seal elements first, ensuring proper alignment. They then install the rotating assembly, paying attention to manufacturer-specified spring compression. Finally, system integration and performance verification, including calibrating flush systems and monitoring during initial startup, ensure optimal operation.

Insufficient Maintenance Practices for Grundfos Pump Seals

A lack of consistent and thorough maintenance practices significantly shortens the lifespan of pump seals. Neglecting regular inspections means plants miss early signs of wear or potential issues. Failing to replace worn components in a timely manner allows minor problems to escalate into major failures. For example, if a plant does not address the root causes of operational stress, such as dry running or frequent start-stop cycles, seals will continue to wear prematurely. Inadequate monitoring of seal performance also prevents proactive intervention. Without a robust maintenance schedule, plants cannot ensure the optimal functioning and longevity of their Grundfos pump seals. This oversight leads to unexpected downtime and increased repair costs.

Implementing Proven Strategies to Prevent Grundfos Pump Seal Leaks

Preventing Grundfos pump seal leaks requires a proactive and multi-faceted approach. Chemical plants can significantly enhance operational reliability and safety by implementing proven strategies. These strategies address material selection, process control, installation practices, and maintenance programs. Comprehensive seal management strategies yield substantial benefits. For instance, plants have reported significant improvements: unscheduled downtime dropped from 15 hours to 0 hours monthly, product losses decreased by 95% (from $20,000 to $1,000), and maintenance and replacement costs fell by 80% (from $10,000 to $2,000). These improvements translate into annual savings of over $336,000.

Optimizing Grundfos Pump Seal Material and Design for Chemical Service

Selecting the correct materials for Grundfos pump seals is paramount in chemical plants. Aggressive media demand seals with superior chemical resistance and durability. For seal faces, materials like Silicon Carbide (SiC) and Tungsten Carbide (WC) offer exceptional hardness, wear resistance, and chemical stability. Silicon Carbide withstands high temperatures and is ideal for harsh chemical and abrasive media. Tungsten Carbide is extremely hard and wear-resistant, suitable for high pressures and abrasive materials.

For secondary seals, or elastomers, Fluorocarbon (Viton) provides excellent chemical and temperature resistance. It suits oil, fuel, and various chemical applications. Perfluoroelastomer (Kalrez) offers superior chemical resistance for pumping highly corrosive fluids. Hardware components, such as springs and other metal parts, often require Hastelloy or Inconel in aggressive environments. These materials provide superior resistance to corrosion and high temperatures.

Grundfos also offers specific seal designs for challenging applications. For example, robust construction with high-grade materials ensures durability against extreme temperatures and corrosive environments. These designs are suitable for petrochemical industries due to their resistance to various aggressive liquids.

Enhancing Process Control and Monitoring for Seal Longevity

Effective process control and continuous monitoring are crucial for extending Grundfos pump seal life. Operators must maintain stable operating conditions to prevent undue stress on seals. Key process parameters require continuous monitoring. These include suction pressure, discharge pressure, flow rate, and fluid temperature. Abnormal fluctuations in these parameters often indicate potential issues that can impact seal integrity. For example, a sudden drop in suction pressure might suggest cavitation, which can damage seals. Monitoring fluid temperature helps prevent overheating, a common cause of seal failure. By closely tracking these variables, plants can identify and address operational anomalies before they lead to seal leaks or catastrophic failures.

Adhering to Best Practice Installation Protocols for Grundfos Pump Seals

Proper installation is as critical as material selection for Grundfos pump seals. Even the most advanced seal will fail prematurely if installed incorrectly. Plants must ensure technicians receive comprehensive training on best practice installation protocols. Several resources offer valuable guidance. The Grundfos Technical Institute provides Quick Tip YouTube Videos specifically addressing seal replacement for various Grundfos pump models. These videos cover safety concerns, removal of components, old seal removal, new seal installation, and final steps before restarting. They also include realignment steps for specific pump types.

Specialized training centers, such as the Process Pump & Seal Training Center, offer classes on pumps and seals. These programs include advanced seal repair and pump and seal reliability. They use various media, hands-on experiences, and physical demonstrations to ensure effective learning. Additionally, courses like TPC Training's 'Pump Installation and Maintenance' include dedicated lessons on 'Maintaining Packing and Seals.' These lessons cover selecting packing material, removing and installing new packing, and troubleshooting mechanical seals. Proper training ensures technicians understand the precision required for seal installation, minimizing errors and maximizing seal lifespan.

Establishing Robust Predictive Maintenance Programs for Grundfos Pump Seals

Implementing robust predictive maintenance programs significantly reduces unexpected Grundfos pump seal failures. These programs focus on identifying potential issues before they escalate. Regular inspections are a cornerstone of predictive maintenance. Technicians conduct routine checks for signs of wear, such as corrosion, pitting, or damage on sealing faces. This allows for early preventive action. Proper lubrication, adhering to manufacturer guidelines for specific lubricants, reduces friction and prevents excessive heat.

When leakage occurs, technicians must troubleshoot effectively. They inspect seals for visible damage like scratches, grooves, or cracks. They also check the seal flush system and chamber for blockages. Addressing excessive heat is vital. Technicians investigate causes such as improper lubrication, shaft misalignment, or blocked cooling/flushing systems. Tools like thermal imaging cameras help identify abnormal heat buildup.

Predictive technologies further enhance these programs. Vibration analysis detects irregular motion and early signs of bearing wear. It tracks changes in vibration patterns to identify bearing misalignment, cavitation, or mechanical failures that impact seals. Thermal imaging and temperature sensors identify abnormal heat buildup caused by friction, misalignment, or lubrication deficiencies. When seals are worn out, plants must follow a strict replacement protocol. This involves shutting down the pump, following safety procedures, thoroughly cleaning sealing surfaces, checking for shaft or sleeve damage, lubricating the new seal, and reassembling properly. For repairable damage, specialized equipment like lapping machines can refinish seal faces, removing imperfections.

Advanced Solutions for Challenging Chemical Plant Grundfos Pump Seal Applications

Chemical plants often encounter extreme conditions that demand more robust sealing solutions. Advanced technologies provide enhanced reliability and safety for these challenging applications. These solutions move beyond standard seals to offer superior performance.

Upgrading to High-Performance Cartridge and Dual Grundfos Pump Seal Systems

Upgrading to cartridge and dual seal systems significantly improves pump reliability. Cartridge seals offer quicker and more accessible installation than component seals. Their pre-assembled and pre-set nature reduces downtime. This design also minimizes human error during installation, leading to greater operational reliability. Grundfos develops innovative sealing solutions to withstand extreme temperatures, high pressures, and aggressive media. These seals use advanced materials like high-performance elastomers and polymers. They also incorporate self-aligning capabilities and optimized geometries for enhanced sealing efficiency.

Utilizing Advanced Barrier Fluid Management for Dual Seals

Dual mechanical seals require effective barrier fluid management. Advanced barrier fluid systems, such as pressurized fluid circulation (API Plans 53 A/B/C), significantly enhance dual pump seal performance. These systems maintain barrier fluid pressure above the stuffing box pressure. This prevents process fluid from reaching seal faces or escaping to the atmosphere. Ideal barrier fluids are compatible with process media and seal materials. They also offer good lubrication and heat transfer. Regular fluid checks for color, viscosity, and solids are crucial for system reliability.

Integrating Smart Monitoring and Diagnostics for Grundfos Pump Seals

Integrating smart monitoring and diagnostics provides real-time insights into seal health. Various sensors track critical parameters. Temperature sensors monitor the thermal conditions of the pump and seal. Vibration sensors detect abnormal vibrations, indicating potential mechanical issues. Pressure sensors track levels within the seal system. Leakage sensors identify any fluid leakage from the seal. This continuous monitoring allows for proactive maintenance and prevents unexpected failures.

Proactive management of Grundfos pump seals is paramount for operational integrity and safety in chemical plants. Preventing leaks relies on a combination of:

- Correct seal selection

- Meticulous installation

- Diligent maintenance

Investing in advanced seal technologies and monitoring systems ensures long-term reliability and efficiency.

FAQ

What causes Grundfos pump seal failures in chemical plants?

Inadequate seal selection, operational stress like dry running, improper installation, and insufficient maintenance practices commonly cause Grundfos pump seal failures.

How can chemical plants prevent Grundfos pump seal leaks?

Plants prevent leaks by optimizing seal materials, enhancing process control, adhering to installation protocols, and establishing robust predictive maintenance programs.

What advanced solutions improve Grundfos pump seal reliability?

Upgrading to cartridge and dual seal systems, utilizing advanced barrier fluid management, and integrating smart monitoring and diagnostics significantly improve reliability.