Minimize the metal to Silicon impact on start–up: Cartridge Seal GWGU1

The GW GU1 Cartridge mechanical seal features a self–aligning stationary design. This directly prevents metal-to-silicon impact during startup. Precise face contact occurs from the first rotation. This eliminates damaging edge loading. The CURC single cartridge seal from supplier GW SEAL ensures immediate protection against premature wear.

Key Takeaways

- The GW GU1 seal has a special design. It lines itself up perfectly when it starts. This stops parts from hitting each other and breaking.

- This seal makes sure all parts touch evenly. This helps the seal last much longer. It also means less fixing and less time the machine is stopped.

- The GW GU1 seal works well from the very start. It keeps working great for a long time. This helps machines run smoothly and saves money.

The Startup Challenge for Cartridge Mechanical Seals

Initial Contact: The Moment of Truth for Seal Faces

The startup phase presents a critical challenge for mechanical seals. Initial contact between seal faces determines the seal's immediate and long-term performance. Many factors compromise this crucial moment. Incorrect installation often leads to early leakage. This includes improper axial setting, uneven tightening of gland bolts, or contaminated seal faces. Dry running or poor lubrication also causes issues. A thin fluid film is essential; without it, seal faces can overheat and crack. Excessive vibration accelerates wear and disrupts alignment. Incompatible seal materials also contribute to gradual leakage. Furthermore, issues like seal faces not being flat enough, secondary sealing mechanism failures, or incorrect seal location on the shaft can cause problems right from the start.

Misalignment Risks: How Minor Deviations Cause Significant Damage

Even minor deviations in alignment cause significant damage to seal faces. Misalignment risks are a major concern for any cartridge mechanical seal. Unevenly tightened gland bolts directly lead to seal face damage. Installation errors, such as incorrect positioning, result in uneven contact and premature wear. Thermal expansion and contraction of components due to temperature changes can also cause seal misalignment. Excessive vibrations from unbalanced parts or external forces dislodge or misalign the seal. Over time, friction between seal faces causes wear, altering alignment. A bent shaft or a lack of concentricity or parallelism between the shaft and seal housing also creates misalignment. Out-of-tolerance assemblies and soft foot conditions further contribute to these issues.

Consequences of Metal-to-Silicon Impact: Chipping, Cracking, and Premature Failure

Metal-to-silicon impact during startup has severe consequences. This impact causes chipping, cracking, and premature failure of the delicate silicon carbide faces. When seal faces do not meet precisely, localized stress points develop. These points experience extreme pressure and friction. This leads to immediate damage. Such damage compromises the seal's integrity. It reduces its lifespan significantly. Ultimately, this results in costly downtime and maintenance.

GW GU1 Cartridge Mechanical Seal: A Self-Aligning Solution

Overview of the GW GU1 Design

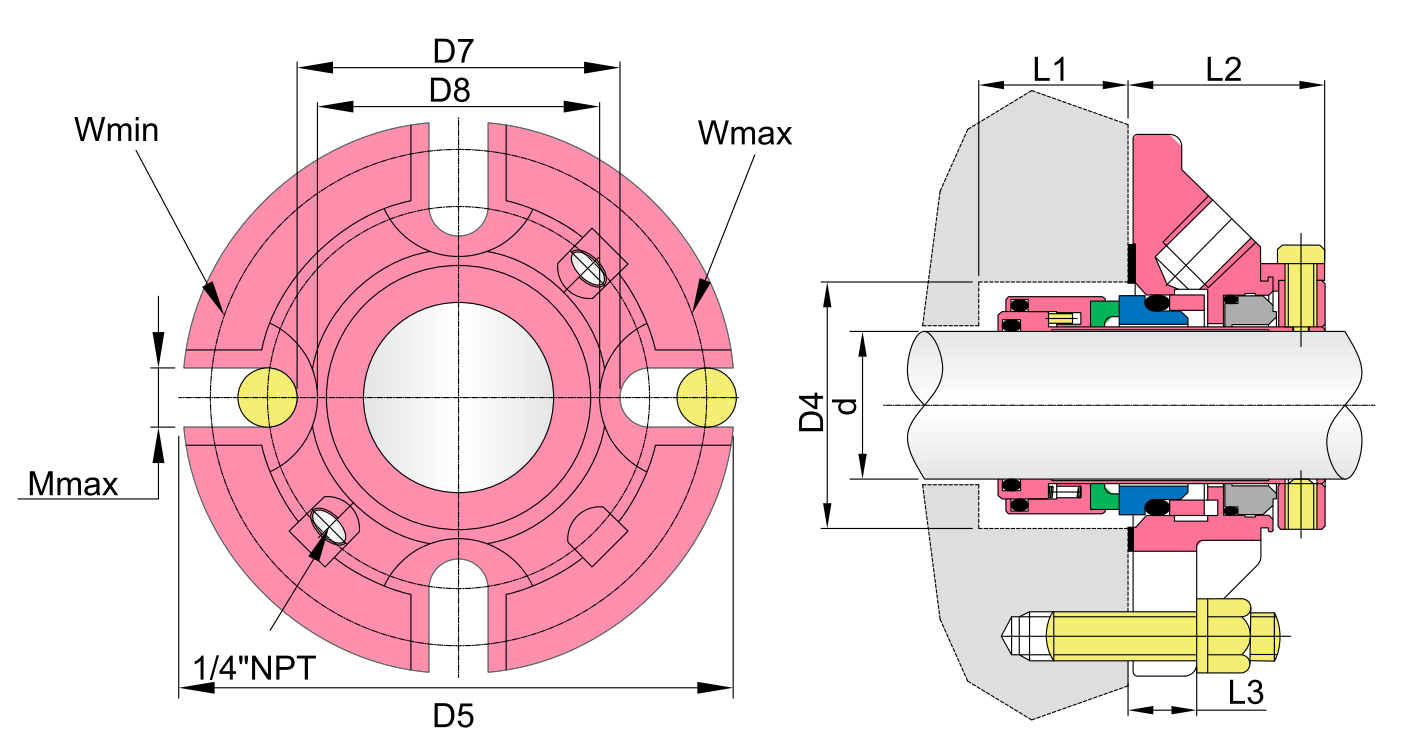

The GW GU1 Cartridge Mechanical Seal CURC represents a significant advancement in sealing technology. This unitized single cartridge design offers a direct, high-performance replacement for existing seals. Its innovative modular construction simplifies installation and enhances reliability. The GW GU1 features self-aligning sealing faces. This intelligent design compensates for minor shaft or housing misalignment. It ensures even wear across the seal faces. This significantly extends the unit's service life. Each GW GU1 seal undergoes full assembly, pre-setting, and rigorous factory testing before shipment. This guarantees operational integrity right out of the box. It also minimizes commissioning time.

The Core Innovation: Explaining the Self-Aligning Mechanism

The GW GU1's core innovation lies in its self-aligning mechanism. This design allows the stationary seal face to adjust its position dynamically. It adapts to any slight angular or radial misalignment between the shaft and the seal housing. This flexibility ensures the seal faces remain parallel during operation. The mechanism uses a unique arrangement of components. These components permit subtle movement of the stationary face. This movement occurs without compromising the seal's integrity. This active compensation prevents the seal faces from meeting at an angle. It eliminates the damaging edge loading common in traditional seals.

Precision from the Start: Ensuring Parallel Face Contact Immediately

The self-aligning feature of the GW GU1 ensures precision from the very first rotation. As the equipment starts, the seal faces immediately achieve parallel contact. This eliminates the initial impact and friction that often damage conventional seals. The design actively guides the faces into optimal alignment. This prevents metal-to-silicon impact. It also avoids the chipping and cracking associated with startup. This immediate precision means the seal begins its operation under ideal conditions. This sets the stage for a long and reliable service life.

Distributing Load Evenly: Preventing Localized Stress Points

Even load distribution is crucial for seal longevity. The GW GU1's self-aligning mechanism excels at this task. It ensures that pressure and friction spread uniformly across the entire sealing surface. This even distribution prevents the formation of localized stress points. In seals without this feature, misalignment creates high-pressure zones. These zones experience accelerated wear and heat buildup. The GW GU1 design mitigates these risks. It maintains consistent contact pressure. This reduces wear rates and extends the operational life of the seal faces.

Protecting Delicate Silicon Carbide Faces

Silicon carbide (SiC) is a preferred material for high-performance seal faces due to its exceptional properties. The GW GU1 design specifically protects these delicate silicon carbide faces. Silicon carbide offers superior hardness and excellent abrasion resistance. It withstands harsh operating conditions, including high pressures, temperatures, and abrasive media. Its high thermal conductivity helps dissipate heat effectively. This prevents thermal distortion and maintains seal integrity. Silicon carbide also boasts excellent chemical resistance, making it suitable for corrosive environments. The material's smooth surface finish reduces friction and wear, prolonging seal life. Furthermore, its high modulus of elasticity provides dimensional stability. This ensures the seal faces remain flat and parallel. The GW GU1's self-aligning mechanism directly prevents the damaging metal-to-silicon impact. This impact can chip or crack these valuable silicon carbide components. By ensuring precise, parallel contact from startup, the GW GU1 maximizes the inherent benefits of silicon carbide. This delivers superior sealing performance and extended durability.

Beyond Startup: Long-Term Benefits of GW GU1 Cartridge Mechanical Seals

Extended Seal Life and Durability

The GW GU1's self-aligning design significantly extends seal life. It ensures even wear across the seal faces. This prevents premature degradation of delicate silicon carbide components. The seal maintains its integrity over longer periods. This robust design contributes to exceptional durability. Users experience fewer unexpected failures. This consistent protection safeguards critical equipment.

Reduced Maintenance and Downtime

Operators benefit from reduced maintenance needs. The extended life of the GW GU1 means fewer seal replacements. This directly translates to less unscheduled downtime. Companies save significant costs on labor and lost production. The reliable performance of this cartridge mechanical seal minimizes operational interruptions. This allows maintenance teams to focus on other priorities.

Consistent Performance and Operational Efficiency

The GW GU1 delivers consistent performance throughout its operational lifespan. Its precise face contact prevents leaks. This ensures stable process conditions. Equipment runs more efficiently. Operators achieve optimal output without interruptions. This reliability enhances overall operational efficiency. It provides peace of mind for demanding applications.

The GW GU1 Cartridge Mechanical Seal's self-aligning design offers a fundamental solution to startup impact. This innovation directly enhances seal longevity. It also significantly reduces operational costs. The GW GU1 delivers superior performance across demanding applications, ensuring reliable operation.

FAQ

What makes the GW GU1 seal self-aligning?

The GW GU1 features an innovative design. It allows the stationary face to dynamically adjust. This compensates for minor shaft or housing misalignment. It ensures parallel contact.

How does self-alignment prevent damage during startup?

It ensures immediate parallel face contact. This eliminates damaging metal-to-silicon impact. It prevents chipping and cracking from the first rotation. This protects delicate silicon carbide.

What are the long-term benefits of the GW GU1's design?

The design extends seal life and durability. It reduces maintenance needs and downtime. It also ensures consistent performance and operational efficiency. This provides significant cost savings.