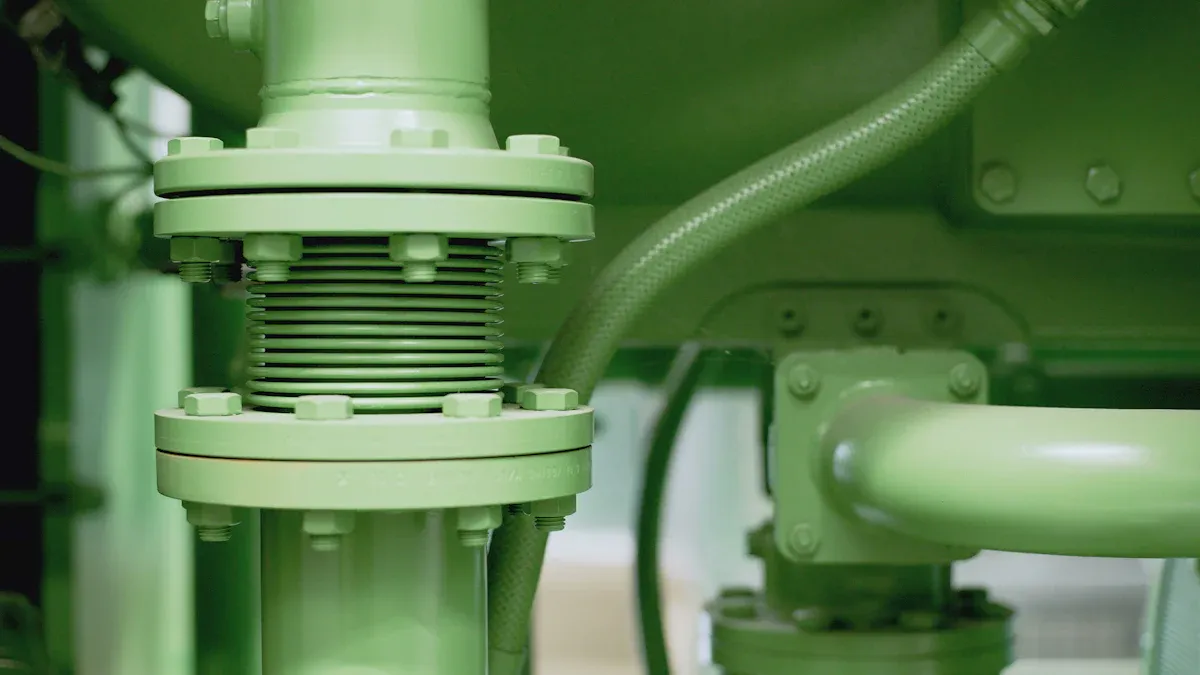

Leak-free Solution: Double Cartridge Mechanical Seal in Pulp and Paper

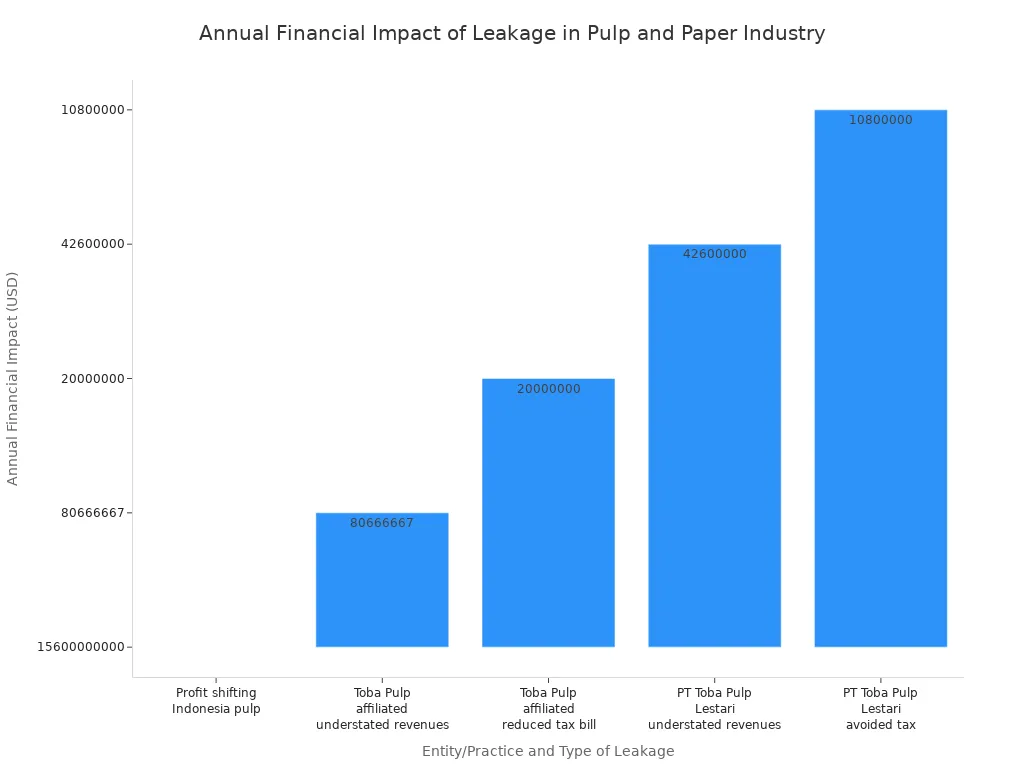

Double Cartridge Mechanical Seals are the definitive answer for leak-free operations in the pulp and paper industry. They offer an optimal strategy for demanding environments. The financial impact of leakage in this sector is significant. For instance, profit shifting in Indonesia's pulp sector alone accounts for at least $15.6 billion in government revenue loss annually. Such figures highlight the critical need for robust sealing solutions. A CDSA, or chemical process seal, provides superior containment.

Key Takeaways

- Double Cartridge Mechanical Seals stop leaks in tough factory jobs. They work well where liquids are rough or can cause rust.

- These seals have two parts and a special liquid in between. This makes them last longer and keeps machines running without stopping.

- Using these seals helps factories save money. They also keep workers safe and protect the environment from harmful leaks.

Understanding Leakage Challenges in Pulp and Paper Operations

The High Cost of Seal Leakage: Downtime, Environmental Impact, and Safety Risks

Seal leakage in pulp and paper operations presents significant financial and operational challenges. It leads to costly downtime, impacts the environment, and creates safety risks for personnel. Equipment failures due to leaking seals often halt production, resulting in lost revenue and increased maintenance expenses. Environmental regulations, such as those outlined in 40 CFR 60 and Texas Commission on Environmental Quality (TCEQ) Permits, mandate strict compliance for industrial emissions. The Environmental Protection Agency (EPA) also enforces Leak Detection and Repair (LDAR) programs to reduce Volatile Organic Compound (VOC) emissions. Non-compliance with these standards can result in substantial fines for companies. Leaking equipment, including pumps and valves, releases VOCs, posing both environmental and health hazards.

Why Traditional Sealing Methods Fall Short in Abrasive and Corrosive Applications

Traditional sealing methods, like packing or single mechanical seals, often fail in the harsh conditions of pulp and paper mills. These environments feature abrasive slurries and corrosive chemicals. Slurries, especially those with hard, sharp particles, cause significant abrasive wear on sealing surfaces. This wear is exacerbated by high-speed rotation. Traditional seals often lack a clean lubricating film between dynamic and stationary surfaces, leading to damage. Hot water used for lubrication can flash into steam at the seal face, causing destructive explosions.

Furthermore, specific chemical compounds in pulp and paper processes actively corrode standard seal materials. These include:

- Hydrogen Sulfide (H₂S) from Kraft pulping.

- Sulfur Dioxide (SO₂) and other sulfur compounds from combustion processes.

- Chlorine (Cl₂) and Chlorine Dioxide (ClO₂) used in bleaching.

- Nitrogen Oxides (NOₓ) and other acidic gases from boilers and kilns.

- Mercaptans and ozone also contribute to corrosion.

These aggressive chemicals degrade polymers, leach components, or cause swelling in sealing materials. This highlights the critical need for chemical compatibility in sealing solutions.

The Double Cartridge Mechanical Seal Advantage: Engineered for Reliability

How Double Cartridge Seals Provide Superior Containment and Extended Operational Life

Double Cartridge Mechanical Seals offer a robust solution for demanding industrial applications. These seals feature two sets of seals. A stationary seal fixes to the housing. A rotating seal slides against it. This forms a strong sealing barrier. A barrier or buffer fluid is introduced between these primary seals. An environmental control system delivers this fluid. This fluid cools and lubricates the seal faces. It also manages the seal's operating temperature. This process establishes ideal lubrication, temperature, and pressure at the seal face. This fluid film control extends the seal's operational life. The fluid also isolates the seal from atmospheric conditions. This protects the seal from external environmental factors. A secondary seal provides an additional layer of protection. This acts as a crucial safety feature if the primary seal fails.

Key Benefits of Double Cartridge Mechanical Seals: Enhanced Reliability and Reduced Maintenance

Double Cartridge Mechanical Seals significantly enhance operational reliability. Their design simplifies installation and maintenance. This ensures better alignment and balance. These factors contribute to an extended lifespan. The superior containment prevents leaks. This reduces product loss and environmental contamination. Companies experience less downtime. They also see lower maintenance costs. The robust construction handles harsh conditions effectively. This makes them ideal for abrasive and corrosive environments.

Types of Double Cartridge Seals and Their Ideal Applications in Pulp and Paper

Double Cartridge Mechanical Seals come in various configurations. These designs suit different operational needs. The primary classifications include back-to-back, tandem, and face-to-face arrangements.

- Back-to-Back Arrangement: The stationary seal faces are opposite each other. The rotating seal faces are on the outer sides. This design is easy to install. It suits many general pumping applications.

- Tandem Arrangement: Two pairs of seals orient in the same direction. This setup is best for toxic or hazardous materials. The outboard seal offers full pressure backup. This provides a safety measure if the inboard seal fails.

- Face-to-Face Arrangement: The rotating seal faces share a single common stationary seal face. This design is useful when equipment space is limited. It works when back-to-back or tandem arrangements are not practical.

Implementing a Leak-Free Strategy with Double Cartridge Mechanical Seals

Selecting the Right Double Cartridge Mechanical Seal: Material Compatibility and Operating Conditions

Choosing the correct Double Cartridge Mechanical Seal is crucial for achieving leak-free operations. Engineers must carefully consider material compatibility and specific operating conditions. The process fluid's chemical composition dictates the selection of seal face materials and elastomers. For highly abrasive pulp slurries, silicon carbide is a frequent choice due to its inherent hardness and wear resistance. Hard face combinations, such as silicon carbide with carbon (SiC/Carbon) or silicon carbide with silicon carbide (SiC/SiC), significantly enhance wear resistance against abrasive media. Other robust materials include resin carbon, antimony carbon, and tungsten carbide.

Beyond material selection, critical operating parameters directly influence seal choice. These parameters include:

- Pressure

- Temperature

- Shaft speed

Each factor impacts the seal's performance and longevity. Engineers must match the seal's design limits to the application's demands to ensure reliable operation.

Barrier Fluid Systems for Double Cartridge Seals: Design, Monitoring, and Maintenance

Barrier fluid systems are integral to the performance of Double Cartridge Mechanical Seals. These systems provide a clean, pressurized fluid between the seal faces, ensuring lubrication and cooling. Various types of barrier fluid systems exist, each suited for different application requirements.

Common API Plans for barrier fluid systems include:

- Plan 53A: This system uses a seal pot pressurized with a blanket of nitrogen gas.

- Plan 53B: This plan utilizes a pre-pressurized bladder accumulator. The bladder prevents gas absorption into the barrier fluid, maintaining fluid integrity.

- Plan 54: This is a larger, external seal support system. It employs a pump and an external reservoir. Plan 54 is designed for applications exceeding Plan 53B's capabilities and can service multiple mechanical seals. It also includes complementary components like filters and coolers for enhanced performance.

The table below highlights key differences between Plan 53B and Plan 54:

| Feature | Plan 53B | Plan 54 |

|---|---|---|

| Operating Principle | Self-contained, uses a bladder accumulator to maintain pressure. | External circulation system with a pump and reservoir. |

| Pressure Source | Pre-pressurized bladder accumulator. | External pump (e.g., centrifugal, positive displacement). |

| Cooling | Often relies on natural convection or small heat exchangers. | Typically includes dedicated heat exchangers (e.g., fin-fan, water-cooled) for efficient cooling. |

| Applications | Suitable for less demanding applications, lower pressures, and temperatures. | Ideal for critical, high-pressure, high-temperature, or hazardous applications. |

| Multi-Seal Support | Typically for a single seal. | Can support multiple mechanical seals from a single system. |

Effective monitoring and maintenance of the barrier fluid system are essential for optimal seal performance. Key parameters to monitor include:

- Environmental Temperature: Fluctuations in environmental temperature can affect gas pressure. Operators must account for these changes when setting system pressures.

- Pre-Charge Pressure: This is the initial pressure set in the gas bladder.

- Refill Alarm Pressure: This minimum barrier pressure indicates the need for system refilling.

- Full Set Point Pressure: This is the pressure at which the system is re-pressurized with new barrier fluid.

Regular checks are also vital. Maintenance teams should perform monthly checks of the fluid for changes in color, viscosity, and the presence of solids. Regular fluid changes are necessary, with frequency increasing at higher temperatures. Monitoring average reservoir temperature, outlet temperature, and inlet temperature provides insight into system health. Operators should also consider the decomposition rate of fluids, which doubles for every 18°F (10°C) rise in temperature. Implementing alarm systems for low/high levels, pressures, and temperatures provides early warnings. For dual seals, regularly inspecting the fluid level and condition in the barrier or buffer fluid system is crucial. Confirming the operating pressure and temperature of the buffer pot or water management system also ensures proper function.

Precision Installation and Commissioning of Double Cartridge Mechanical Seals for Long-Term Reliability

Precision during installation and commissioning directly impacts the long-term reliability of Double Cartridge Mechanical Seals. Proper alignment of the pump and its components is paramount. This prevents excessive vibration and premature seal failure. Misalignment leads to uneven wear on the sealing faces, which results in leaks. Installers must follow the manufacturer's guidelines for alignment procedures and use appropriate tools.

During the commissioning phase, essential post-installation checks confirm proper setup. These checks include:

- Performing a Pressure Test: This test confirms no leakage occurs under the specified test pressure.

- Running a Dry Rotation Check: This check ensures the shaft rotates smoothly without obstruction.

- Monitoring Initial Operation: During the initial operational period, operators must watch for unusual signs such as noise, vibration, or excessive heat build-up.

After initial startup, the pump should be stopped. This allows for an inspection of the mechanical seal and its associated piping for any signs of wear, thermal distortion, or debris. All pressure, temperature, and flow readings taken during startup must be recorded and compared against baseline values. Any deviations from these baselines require investigation. A subsequent inspection should be scheduled after the first few hours of operation, as initial wear patterns can reveal installation issues.

Proactive Maintenance and Troubleshooting for Double Cartridge Mechanical Seals

Proactive maintenance and effective troubleshooting are key to maximizing the lifespan and performance of Double Cartridge Mechanical Seals. Recognizing common indicators of impending failure allows for timely intervention.

Common indicators of impending failure include:

- Visible Leakage: Fluid seeping around the seal faces or gland plate.

- Excessive Heat: The seal area feels unusually hot due to friction or dry running.

- Unusual Noise or Vibration: Misalignment or improper lubrication can cause chatter.

- Short Seal Life: Seals fail much earlier than expected.

- Contamination: Seal faces are damaged by dirt, chemicals, or foreign particles.

Specific seal face issues also indicate problems:

- Deep Grooves on Seal Face: Inadequate lubrication or abrasive materials in the process fluid cause these. Troubleshooting involves flushing the seal with an appropriate plan, considering abrasive-resistant seal face materials, and preventing scaling or crystallization.

- Even vs. Uneven Wear Track: An uneven wear pattern indicates distortion from overtightening, clamping, excessive pressure, elevated temperatures, or an insufficiently wide hard face. Troubleshooting requires reviewing installation guidelines, techniques, and operating conditions.

- Fractured or Cracked Seal Face: Thermal shock or mechanical impact causes these. Troubleshooting includes avoiding uneven or overtightening fasteners, maintaining a consistent seal flush plan, and eliminating the source of shock or impact.

- Chips, Cracks in Seal Ring: Improper installation and mishandling of parts often cause these. Troubleshooting involves following proper installation guidelines and avoiding direct contact with brittle seal face materials.

Troubleshooting steps address these issues:

- Identify the Source of Leakage: Check for gasket/O-ring wear, improper gland tightening, or secondary sealing element failures.

- Inspect Installation Practices: Ensure clean surfaces, correct alignment, and proper torque on gland bolts.

- Check for Shaft Misalignment: Use alignment tools to detect and correct issues that cause uneven wear.

- Evaluate Operating Conditions: Verify that temperature, pressure, and fluid properties are within manufacturer's recommendations.

- Look for Dry Running: Address causes like air pockets, inadequate priming, or closed valves; consider a seal support system or flush plan.

- Analyze Material Compatibility: Ensure seal face materials and elastomers are compatible with the process fluid.

- Monitor Vibration and Bearing Condition: Inspect bearings and shaft condition as excessive vibration stresses seals.

Addressing bad maintenance practices is also crucial. Lack of routine inspections or incorrect maintenance leads to failures. Solutions include routine checks, training maintenance workers, and logging maintenance activities. Seal blowout, caused by excessive pressure due to incorrect installation or insufficient retention, requires choosing seals rated for the highest system pressure, installing retention devices, and including relief valves. For aging and wear, continuous operation leads to degradation. Solutions include monitoring seals for wear and replacing them promptly, using advanced materials for longer stability, and implementing predictive maintenance programs.

Real-World Success: Case Studies with Double Cartridge Mechanical Seals

Examples of Significant Leak Reduction and Uptime Improvement in Pulp and Paper Mills

Double Cartridge Mechanical Seals consistently deliver tangible benefits in challenging pulp and paper environments. One notable case involved a pulp mill struggling with high maintenance costs for their recovery boiler feed pumps. These pumps handled black liquor, a byproduct crucial for energy generation and pulp drying. The mill faced significant expenses maintaining the consistency and viscosity of this black liquor.

The primary issues included flush water contaminating the process stream and black liquor leaking into the work area. These problems led to increased chemical make-up costs and safety concerns.

Implementing Double Cartridge Mechanical Seals on these critical pumps transformed their operation. The new seals provided superior containment, effectively stopping the black liquor leakage. This eliminated the need for constant flush water, preventing process contamination. Consequently, the mill significantly reduced its make-up chemical expenses. They also improved the overall consistency of the black liquor. The enhanced reliability of the seals drastically cut pump downtime. This resulted in substantial uptime improvement and a safer working environment for personnel. This case demonstrates how advanced sealing technology directly impacts operational efficiency and cost savings.

Companies must evaluate their current sealing strategies. Adopting Double Cartridge Mechanical Seals significantly enhances operational efficiency, safety, and environmental compliance. Businesses achieve leak-free perfection by implementing these advanced Double Cartridge Mechanical Seal solutions. This ensures reliable and sustainable operations across the pulp and paper industry.

FAQ

What is a Double Cartridge Mechanical Seal?

Double Cartridge Mechanical Seals feature two sets of seals with a barrier fluid between them. This design provides superior containment and extends operational life.

Why are Double Cartridge Mechanical Seals ideal for pulp and paper?

They offer enhanced reliability and reduced maintenance in abrasive and corrosive environments. Their robust design prevents leaks and handles harsh conditions effectively.