Innovating Mechanical Seals as Your China OEM Partner

Strategic partnerships with China OEM mechanical seals manufacturers are crucial in 2025. Companies require advanced, reliable, and cost-effective sealing solutions. This approach moves beyond simple transactions. It fosters collaborative innovation, shared risk, and mutual growth. The mechanical seals market projects a 6.2% CAGR from 2024 to 2025. A strong China OEM Partner, like GW SEAL, can leverage this expansion.

Key Takeaways

- Strategic partnerships with China OEM mechanical seal makers are important. They bring new ideas, share risks, and help everyone grow.

- New ideas in mechanical seals include better materials, smart seals with internet connections, and eco-friendly ways to make them. Custom designs and quick testing are also key.

- Choosing the right partner means checking their innovation, working together on designs, and making sure they have good quality control. This helps make sure seals are reliable and meet high standards.

The Evolving Landscape for China OEM Mechanical Seals

Global Supply Chain Resilience and Diversification

The global supply chain landscape is undergoing significant transformation. Companies actively pursue diversification strategies. The US share of China's total exports decreased from 19.3% in 2018 to 14.7% in 2024. This shift reflects a broader trend. Many businesses now reduce their reliance on direct China-based manufacturing. They adopt a 'China Plus One' strategy. Manufacturing volume has moved to Southeast Asian nations like Vietnam and India. China itself transitions to a more sophisticated manufacturing environment. Nearshoring strategies also simplify supply chain complexity. This reduces risks associated with unpredictable tariffs and trade barriers. Businesses avoid single-source manufacturing to enhance resilience. This evolving environment makes strategic partnerships with China OEM mechanical seals manufacturers even more critical.

Demand for Advanced Sealing Technologies

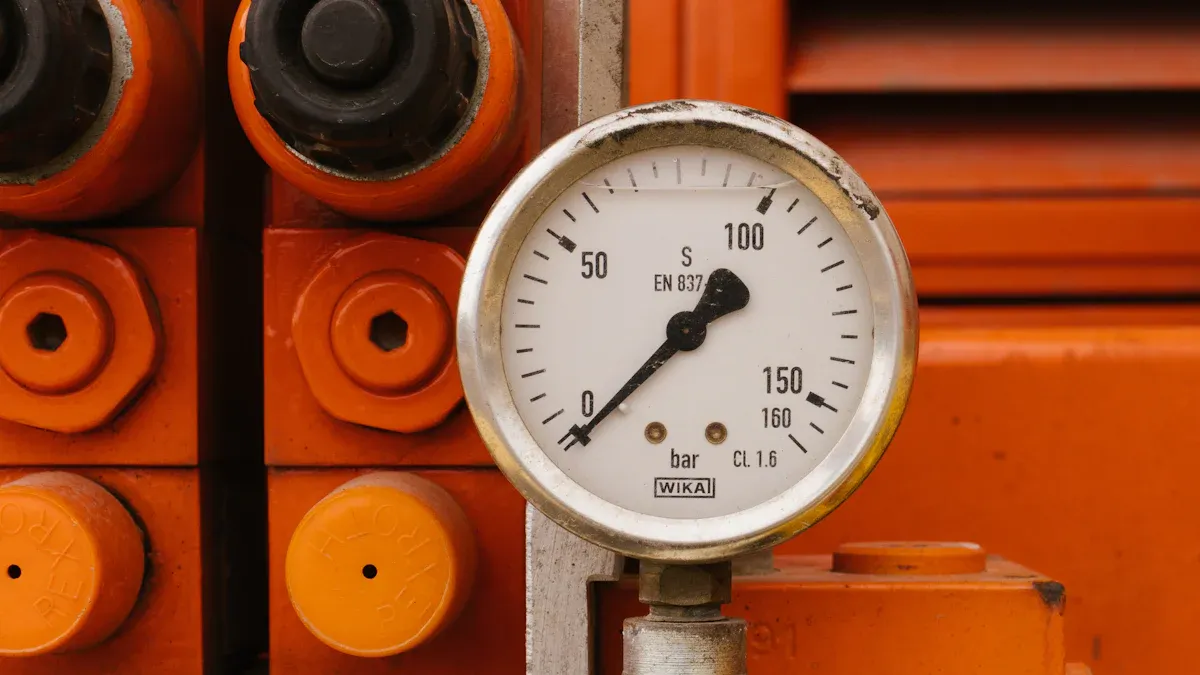

Demand for advanced sealing technologies continues to grow across various industries. Applications in water and wastewater treatment, pharmaceutical processing, and energy generation require robust solutions. The oil and gas industry remains a dominant user of mechanical seals. It needs reliable seals for pumps and compressors handling aggressive fluids. The water and wastewater sector is the fastest-growing segment. It requires efficient seals for critical infrastructure. Aerospace also shows rapid growth, demanding high-performance seals for extreme conditions. Innovations include smart materials like self-healing polymers. Integrated monitoring systems with sensors provide real-time performance data. Custom-made seals precisely fit specific application requirements. These solutions address limitations of off-the-shelf products. They handle extreme pressures or temperatures. Materials like Fluoroprene XP and FFKM compounds offer superior chemical resistance and durability.

Cost Optimization vs. Value Creation

Companies increasingly balance cost optimization with value creation in mechanical seal procurement. They move beyond initial purchase price. Instead, they focus on the total cost of ownership (TCO). Suppliers address price objections by providing transparent cost breakdowns. This shows how premium materials or R&D investments justify pricing. They also offer alternative solutions to meet budget constraints. These solutions still meet performance requirements. Demonstrating lifecycle savings is crucial. Higher-quality seals reduce failure rates, maintenance costs, and unplanned downtime. This approach emphasizes long-term benefits. Strategic partnerships foster continuous product improvements and preferential pricing. These agreements can include technology upgrades and performance monitoring. This ensures both cost efficiency and innovation.

GW SEAL: A Blueprint for Strategic China OEM Mechanical Seals Partnership

GW SEAL offers a clear blueprint for strategic partnerships in the China OEM mechanical seals sector. The company combines advanced capabilities with a customer-centric approach. This creates a reliable and innovative partner for sealing solutions.

Advanced Material Expertise and Customization

GW SEAL demonstrates advanced material expertise. It provides extensive customization for unique mechanical seal applications. The company designs and manufactures seals to perfectly fit specific customer requirements. This ensures optimal performance, durability, and cost-effectiveness.

Our company specializes in customizing sealing products to meet specific customer requirements. We utilize advanced technology and skilled expertise to design and manufacture seals that are a perfect fit for your application. Our customization capabilities ensure optimal performance, durability, and cost-effectiveness for our sealing solutions. We are committed to delivering high-quality, tailor-made products that address your unique needs.

GW SEAL manufactures seals from customer samples or drawings. It also designs seals based on specific requests. Material changes are possible to achieve different operating parameters.

Precision Manufacturing and Quality Control

GW SEAL maintains strict quality control throughout its manufacturing process. It selects only high-quality materials. Each product undergoes hand-inspection and machine-testing. This ensures superior functionality and durability before reaching the customer.

Collaborative R&D and Engineering Support

A professional R&D team drives innovation at GW SEAL. This highly skilled team constantly optimizes product performance. They also expand product coverage. GW SEAL offers a range of cartridge seals and OEMs. They provide professional technical advice based on customer consultations. Effective technical assistance and repair services enhance customer experience.

Efficient Inventory and Supply Chain Reliability

GW SEAL manages inventory efficiently. It holds a large inventory. This greatly shortens product lead times. It also reduces customer supply chain risks. This commitment to efficiency ensures reliable and timely delivery for partners.

Case Studies: Realizing Strategic Advantage with China OEM Mechanical Seals

Enhanced Performance in High-Pressure Applications

Companies achieve significant operational improvements by implementing advanced mechanical seals in high-pressure environments. Dual mechanical seals offer superior reliability and safety. They use a barrier or buffer fluid. These seals virtually eliminate process fluid leakage. They also prevent catastrophic leakage of process fluids under high pressure. This design improves control over the seal environment and seal face lubrication. It extends seal life, leading to a better mean time before failure (MTBF).

| Industry/Facility | Performance Enhancement |

|---|---|

| Chemical Processing Plant | Reduced pump downtime by 40% and extended MTBF by 150% through the implementation of cartridge mechanical seals, leading to significant savings in maintenance costs and increased productivity. |

| Oil and Gas Refinery | Improved operational safety and environmental compliance by virtually eliminating hazardous emissions with dual mechanical seals, resulting in a 95% reduction in fugitive emissions. |

| Power Generation Facility | Extended pump life by 50% and reduced maintenance frequency by 60% through the adoption of heavy-duty mechanical seals designed for abrasive slurries, resulting in improved reliability and lower operational expenses. |

These examples demonstrate the tangible benefits of upgrading sealing solutions. They highlight enhanced safety, reduced downtime, and improved environmental compliance.

Accelerated Market Entry with Custom Solutions

Strategic partnerships with OEM manufacturers enable rapid market entry for specialized products. Companies leverage the OEM's expertise in customization and rapid prototyping. This allows them to quickly develop and test tailored sealing solutions. For instance, a pharmaceutical company needed a sterile, contamination-free seal for a new drug delivery system. A responsive OEM partner designed and prototyped a custom hygienic seal within weeks. This accelerated the product's regulatory approval and market launch. Similarly, an aerospace firm required lightweight, high-performance seals for a new aircraft component. The OEM's ability to work with advanced materials and provide quick iterations allowed the firm to meet stringent deadlines. This facilitated a faster introduction of their innovative component to the market.

Strategic partnerships with innovative manufacturers are essential for competitive advantage in 2025. Companies unlock unprecedented value by focusing on innovation, collaboration, and a shared vision. This secures a resilient future for sealing solutions. Such partnerships emphasize R&D investment for enhanced performance and customized solutions, ensuring product reliability and compliance with high industry standards.

FAQ

What makes strategic partnerships with China OEM mechanical seal manufacturers crucial?

Strategic partnerships offer advanced, reliable, and cost-effective sealing solutions. They foster collaborative innovation, shared risk, and long-term mutual growth. This moves beyond traditional buyer-seller dynamics.

What key innovations define China OEM mechanical seals for 2025?

Innovations include material science breakthroughs, smart seals with IoT integration, and sustainable manufacturing. Customization and rapid prototyping also drive advancements.

How does GW SEAL support efficient inventory and supply chain reliability?

GW SEAL maintains a large inventory. This significantly shortens product lead times. It also reduces customer supply chain risks, ensuring reliable and timely delivery for partners.