How to Prevent Seal Failure with SiC and Carbon in Acid Pumps

Preventing seal failure in acid pumping applications is critical for operational reliability and safety. Selecting the right Seal Face Material, specifically Silicon Carbide (SiC) and Carbon, is key to achieving this prevention. This post explains how the unique properties of SiC and Carbon contribute to preventing seal failure in corrosive environments, as detailed in the GW SEAL Technical Reference Guide. GW SEAL promotes informed material selection.

Key Takeaways

- Silicon Carbide (SiC) is a strong material for acid pumps. It stops acids from causing damage and resists wear from small, hard particles.

- Carbon is also good for acid pumps. It does not react with many chemicals and lubricates itself, which helps seals last longer.

- Using SiC and Carbon together makes seals very strong. This combination helps seals work well in tough conditions, like high heat or when pumping abrasive liquids.

Understanding Acid Pumping Challenges for Mechanical Seal Face Material

Corrosive Nature of Acids on Seal Face Material

Acids present a significant challenge to mechanical seals due to their highly corrosive nature. They chemically attack and degrade many common Seal Face Material options. This chemical assault can lead to material dissolution, pitting, and erosion, compromising the seal's integrity. Over time, this degradation causes leaks and ultimately results in seal failure. Therefore, selecting materials with exceptional chemical inertness is paramount for reliable operation in acidic environments.

Impact of Abrasive Particles on Seal Face Material

Beyond corrosion, acid pumping applications often involve abrasive particles suspended within the fluid. These particles, even in small concentrations, can cause significant wear and damage to the Seal Face Material. As the seal faces rotate, these hard particles act like sandpaper, scratching and eroding the surfaces. This abrasive wear creates pathways for leakage and reduces the effective lifespan of the seal. High hardness and wear resistance are crucial properties for materials operating under such conditions.

Effects of Temperature and Pressure Extremes on Seal Face Material

Acid pumps frequently operate under extreme temperature and pressure conditions, which severely impact seal performance. High temperatures cause materials to expand, while lower temperatures lead to shrinkage. Both scenarios can exceed the seal's design tolerance, negatively affecting critical components. Thermal shock, a sudden and rapid cooling of a heated component, can fracture seal faces. Furthermore, heat checking, or cracking, occurs due to differences in thermal expansion coefficients within composite materials. If the seal temperature becomes excessively high, the face material will crack, blister, heat check, and ultimately fail. Repeated heating and cooling cycles, known as thermal cycling, place seals under constant stress, leading to cracking, deformation, or a loss of sealing ability if materials cannot adapt. High temperatures also accelerate the breakdown of molecular bonds in elastomers, causing them to harden, crack, or fail. This also leads to compression set, where a material cannot return to its original shape after prolonged compression and high-temperature exposure, resulting in lost contact and leaks.

Silicon Carbide (SiC) as a Robust Seal Face Material for Acids

Exceptional Corrosion Resistance of SiC Seal Face Material

Silicon Carbide (SiC) stands out as a premier material for mechanical seals in acid pumping applications due to its remarkable chemical inertness. This property means SiC resists chemical attack from a wide array of aggressive substances, including strong acids and alkalis. Sintered silicon carbide, a common and widely used hard face material, is produced from pure silicon carbide powder with non-oxide sintering aids. It forms a homogeneous structure without free silicon, making it impervious. The absence of free silicon renders Sintered silicon carbide chemically inert to virtually all corrosive environments. This characteristic makes it highly resistant to chemically aggressive fluids and suitable for use in virtually any fluid, including acid service. Engineers recognize SiC for its superior acid and alkali corrosion resistance, making it an excellent material for mechanical seals, sliding bearings, and corrosion-resistant pipes in the chemical industry. Its acid and alkali resistance are considered exceptional, surpassing many other materials.

High Hardness and Wear Resistance of SiC Seal Face Material

The extreme hardness of Silicon Carbide provides exceptional resistance to wear and abrasion, a critical factor in preventing seal failure. Acidic fluids often contain abrasive particles that can quickly degrade softer materials. SiC's inherent hardness allows it to withstand the erosive effects of these particles, maintaining the integrity of the sealing surfaces. Silicon carbide (SiC) seal face material has an extremely high hardness, often above 2500 HV (Vickers hardness). This high hardness ensures a long operational life even in challenging conditions.

| Properties | Unit | SSiC |

|---|---|---|

| Vickers Hardness | HV0.5 | ≥2200 |

SiC achieves approximately 2500–2800 HV (Vickers Hardness) and also has a Vickers Hardness of ~3,000 HV. This superior hardness minimizes wear, preventing leakage pathways and extending the lifespan of the mechanical seal.

Thermal Stability of SiC Seal Face Material

Silicon Carbide exhibits excellent thermal stability, a crucial attribute for seals operating in environments with fluctuating temperatures. It possesses high thermal conductivity, which helps dissipate heat generated during operation, reducing the risk of thermal stress. SiC also demonstrates strong resistance to thermal shock, meaning it can endure rapid temperature changes without cracking or fracturing. This stability ensures the seal maintains its performance even when exposed to significant temperature variations.

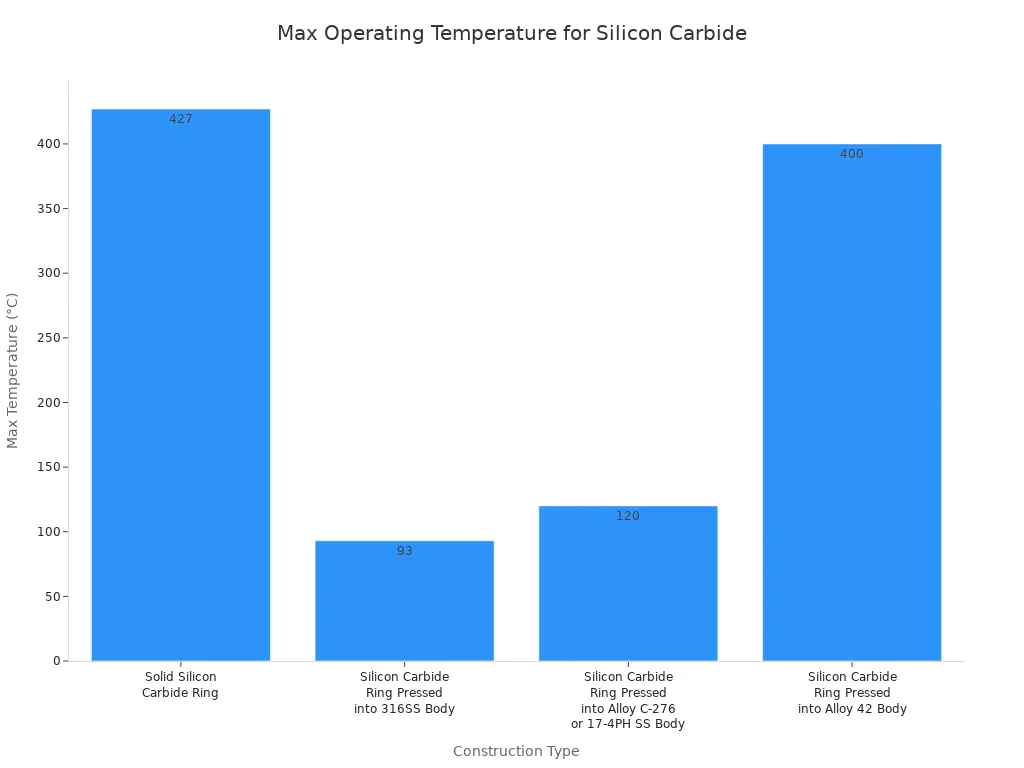

The maximum operating temperature for SiC varies depending on its construction:

| Construction | Max Temperature |

|---|---|

| Solid Silicon Carbide Ring | 800°F (427°C) |

| Silicon Carbide Ring Pressed into 316SS Body | 200°F (93°C) |

| Silicon Carbide Ring Pressed into Alloy C-276 or 17-4PH SS Body | 250°F (120°C) |

| Silicon Carbide Ring Pressed into Alloy 42 Body | 750°F (400°C) |

These temperature capabilities highlight SiC's suitability for demanding high-temperature acid applications.

Optimal Applications and Considerations for SiC Seal Face Material

Silicon Carbide is ideal for a broad range of acid pumping applications where corrosion, abrasion, and high temperatures are significant concerns. Its robust properties make it indispensable in the chemical processing industry for pumps transporting aggressive chemicals. SiC handles nearly all acids, alkalis, and solvents, maintaining resistance even at elevated temperatures. This allows for the safe pumping of a wide range of fluids. It is also ideal for transporting hot fluids and operating in environments with thermal shocks due to its ability to retain strength under high temperatures.

Specific applications where SiC demonstrates superior performance include:

- CQBF Fluorine-lined Magnetic Pumps with Silicon Carbide (SSiC) sintered sliding bearings. These are designed for applications with extremely high corrosion properties.

- Handling a wide range of inorganic substances, as well as highly corrosive weak acids and bases, within a temperature range not exceeding 260°C.

- Chemical pumps within alkaline electrolyzers.

- Handling aggressive chemical environments, including sulfuric acid (H2SO4).

When selecting SiC, engineers consider the specific acid type, concentration, and operating temperatures to ensure the chosen SiC grade and construction provide optimal performance and longevity.

Carbon as a Versatile Seal Face Material in Acid Sealing

Chemical Inertness of Carbon Seal Face Material

Carbon graphite offers good chemical resistance to a wide range of chemicals, including many acids. This property makes it suitable for chemical processing applications where it must withstand corrosive substances. Its chemical resistance can vary based on the specific type of carbon graphite and the chemicals involved. While some highly oxidizing chemicals might challenge carbon graphite, it generally provides significant protection against common industrial chemicals.

For example, when considering hydrochloric acid, carbon graphite's performance can be evaluated in conjunction with common elastomers often used in carbon seals.

| Hydrochloric Acid Concentration | Neoprene (often used with carbon seals) | Buna-N/Nitrile (often used with carbon seals) |

|---|---|---|

| 10% | A (Excellent) | B (Good) |

| 20% | B (Good) | B (Good) |

| 25% | B (Good) | C (Fair) |

| 38% | C (Fair) | C (Fair) |

| 50% | D (Severe Effect) | D (Severe Effect) |

| 100% | D (Severe Effect) | D (Severe Effect) |

| Concentrated | D (Severe Effect) | D (Severe Effect) |

| 3 Molar | C (Fair) | C (Fair) |

This table shows that as hydrochloric acid concentration increases, the resistance of these elastomers decreases. In aggressive chemical transfer applications, such as those involving concentrated hydrochloric acid, SiC is often the preferred choice over carbon due to its exceptional resistance. This suggests carbon may have limitations compared to SiC in highly concentrated or extremely aggressive acid environments.

Self-Lubricating Properties of Carbon Seal Face Material

Carbon's inherent self-lubricating properties significantly reduce friction between mating surfaces. This characteristic is crucial for mechanical seals, as it minimizes heat generation and wear during operation. The layered structure of graphite allows its atomic planes to slide easily over each other, providing a natural lubricating effect. This self-lubrication helps maintain a stable fluid film between the seal faces, even under marginal lubrication conditions.

When carbon (C(PES)) pairs with silicon carbide (SiC), dry friction tests show a mean friction coefficient as low as 0.1. Overall, silicon carbide (SiC), a common mating material for carbon seal faces, generally exhibits a coefficient of friction in the range of 0.2–0.7 in dry sliding conditions. This low friction extends the seal's operational life and reduces power consumption.

Thermal Shock Resistance of Carbon Seal Face Material

Carbon exhibits remarkable thermal shock resistance. This property allows it to withstand rapid and extreme temperature changes without cracking or fracturing. In acid pumping applications, where temperatures can fluctuate significantly, carbon's ability to absorb thermal stress is a major advantage. It also possesses good thermal conductivity, which helps dissipate heat away from the Seal Face Material, preventing localized hot spots and thermal degradation. This combination of properties ensures the seal maintains its integrity and performance even in thermally demanding environments.

Synergistic Benefits of SiC-Carbon Seal Face Material Pairings

Pairing Silicon Carbide with carbon in mechanical seals offers synergistic benefits, leveraging the strengths of both materials for superior performance in acid pumps. This combination creates an optimal thermal environment, maintaining consistent face contact and preventing thermally induced seal failure. SiC's ability to maintain structural integrity above 1000°C and its low thermal expansion prevent distortion, while carbon's excellent thermal conductivity dissipates heat and its remarkable thermal shock resistance prevents hot spots. Together, they extend service life by preventing thermal degradation.

This pairing also delivers exceptional wear resistance and durability. SiC's Mohs hardness of 9.5 provides outstanding resistance to abrasive particles and erosive fluids, allowing operation for years with minimal wear in slurries. Carbon's self-lubricating properties form beneficial wear patterns, improving sealing over time. It also accommodates minor irregularities and wear debris, providing flexibility and shock absorption. This combination enables reliable operation for years with minimal maintenance, even in marginal lubrication or dry running conditions, reducing the total cost of ownership.

Furthermore, the SiC-carbon pairing offers excellent chemical compatibility and resistance. SiC provides exceptional resistance to acids, bases, solvents, and corrosive media, maintaining integrity in aggressive chemical processing environments. Carbon offers excellent compatibility with hydrocarbons, water-based fluids, and many industrial chemicals. Its graphitic structure provides natural lubrication and absorbs process fluid for a self-lubricating film. This allows for optimal material pairing for specific applications, such as using a SiC stationary face with a carbon rotating face for abrasive slurries with chemical components. This ensures long-term reliability and performance, extending service intervals, reducing maintenance costs, and improving plant uptime.

Strategic Seal Face Material Selection for Optimal Seal Life

Matching Seal Face Material to Acid Type and Concentration

Choosing the correct Seal Face Material begins with understanding the specific acid. Different acids possess varying corrosive strengths. For instance, highly concentrated sulfuric acid demands materials with exceptional chemical inertness, like Silicon Carbide (SiC). Weaker acids or specific concentrations might allow for carbon graphite. Engineers must carefully evaluate the acid's chemical composition and concentration. This ensures the selected material resists degradation and maintains seal integrity over time.

Considering Operating Conditions for Seal Face Material Choice

Operating conditions significantly influence material selection. Factors like temperature, pressure, and pump speed all play a role. Higher pump speeds increase frictional heat and wear. This necessitates the use of harder face materials for mechanical seals. This is a crucial factor in selecting the appropriate Seal Face Material to ensure performance and longevity.

| Criteria | Considerations |

|---|---|

| Friction & Wear | Opt for harder materials if faced with high speeds leading to friction wear. |

Extreme temperatures can also affect material stability. High pressures can deform softer materials. Therefore, engineers select materials that withstand these specific operational demands.

Importance of Material Compatibility for Seal Face Material

All components within a mechanical seal system must work together. This includes the primary seal faces, secondary seals (like O-rings), and hardware. Incompatible materials can lead to accelerated corrosion or degradation. For example, an elastomer O-ring incompatible with the pumped acid will fail, regardless of the primary seal face material. Engineers ensure all parts exhibit chemical resistance to the process fluid. This holistic approach prevents premature seal failure and extends operational life.

Best Practices for SiC and Carbon Seal Face Material Longevity

Proper Installation Techniques for SiC and Carbon Seals

Correct installation is paramount for the longevity of SiC and carbon seals. Installers must follow precise steps to prevent premature failure.

- Inspect the Cartridge Unit: Check for any shipping damage, scratches, or chips on the seal faces. Verify all components are intact.

- Verify Compatibility: Confirm the seal matches the equipment's shaft size, housing bore, and application parameters.

- Clean the Cartridge Seal: Wipe the seal with a lint-free cloth. Avoid disassembling the unit unless specific instructions require it.

- Shaft and Housing Preparation: Clean and inspect the shaft for damage. Install a shaft sleeve if necessary. Clean the housing bore thoroughly.

- Install the Cartridge Seal: Align the seal with the housing bore and shaft. Slide it into place, ensuring the rotating component moves freely.

- Secure the Cartridge Flange: Insert and hand-tighten the mounting bolts.

- Align the Cartridge Seal: Use a dial indicator to check and adjust alignment. Aim for runout less than 0.05 mm.

- Torque the Mounting Bolts: Tighten bolts in a crisscross pattern according to manufacturer specifications.

- Remove Installation Aids: Remove temporary aids only after fully securing the cartridge.

- Post-Installation Testing: Conduct static and dynamic leak tests to ensure proper function and no leaks.

Regular Monitoring and Maintenance of SiC and Carbon Seals

Regular monitoring and maintenance extend the life of SiC and carbon seals. Operators should routinely inspect seals for signs of wear or leakage. Early detection of issues allows for timely intervention. This prevents minor problems from escalating into major failures. Scheduled maintenance, including seal face inspection and component replacement, ensures optimal performance. Proactive maintenance reduces unexpected downtime and operational costs.

System Design Considerations for SiC and Carbon Seal Life

System design significantly impacts SiC and carbon seal longevity. Flush plan selection directly influences heat dissipation and lubrication. An efficient cooling system, integral to a flush plan, manages and disperses generated heat. Inadequate cooling leads to localized heating and material degradation. This diminishes sealing performance and shortens seal lifespan.

A properly functioning flushing system is crucial for dissipating heat. "A cool seal is a happy seal" highlights effective heat management. Environmental control systems, including flush plans, prevent negative effects from transients. They remove frictional heat, reduce solids in the flush flow, and optimize conditions. This prevents vaporization or freezing, all contributing to extended seal life.

Strategic use of Silicon Carbide and Carbon as seal face materials significantly reduces seal failure in acid pumping. Adhering to best practices in material selection, installation, and maintenance improves operational reliability and reduces downtime. Engineers make informed decisions by understanding these materials' unique properties and applications. This prevents costly seal failures.

FAQ

What makes Silicon Carbide (SiC) ideal for acid pumps?

SiC offers exceptional corrosion resistance to strong acids and alkalis. Its high hardness also protects against abrasive particles, ensuring long-term seal integrity in demanding environments.

Why do engineers choose carbon for some acid sealing applications?

Carbon provides chemical inertness to many acids and possesses self-lubricating properties. This reduces friction and wear, extending seal life in various applications where chemical compatibility is crucial.

How do SiC and carbon work together in mechanical seals?

Pairing SiC and carbon combines SiC's extreme hardness and corrosion resistance with carbon's self-lubrication and thermal shock resistance. This creates a highly durable and efficient seal system.