How to Prevent Leaks Choosing the Right Screw Pump Seal

Preventing leaks in marine fuel and lube oil transfer systems is crucial. It ensures operational efficiency, safety, and environmental compliance. Selecting the appropriate screw pump seal is the most effective strategy. This choice considers specific operating conditions and fluid characteristics. This guide details critical factors and seal types for leak-free operation.

Key Takeaways

- Choosing the right screw pump seal is important. It stops leaks in marine fuel systems. This keeps the environment safe and helps ships run well.

- Mechanical seals are the best choice. They handle high pressure and stop almost all leaks. This makes them good for tough marine jobs.

- Install seals correctly and check them often. This makes them last longer. It also helps avoid costly repairs and keeps the ship safe.

Understanding the Critical Role of Screw Pump Seals in Marine Operations

Why Leaks are Detrimental: Environmental, Safety, and Operational Impacts

Leaks in marine fuel and lube oil systems pose significant threats. They create severe environmental, safety, and operational problems. Environmentally, oil discharges into navigable waters or shorelines require immediate reporting to the EPA. These include any discharges that create a film, sheen, or discoloration on the water's surface. The Spill Prevention, Control, and Countermeasure (SPCC) Rule and the Facility Response Plan (FRP) Rule aim to prevent such incidents. The U.S. Coast Guard leads responses for spills in coastal waters.

Safety concerns are paramount. Leaks of flammable oil, especially near ignition sources, present a major fire hazard. Engine rooms contain fuel, oxygen, and heat sources like turbochargers, which operate above 400°C. Even small oil leaks contacting these hot surfaces can ignite instantly. Older vessels face higher fire risks due to degrading insulation and inconsistent maintenance. Operationally, pump failures, often due to seal issues, cause costly downtime and disrupt entire operations. A single pump failure can halt production or compromise a vessel's safety at sea. Implementing reliable mechanical seals, such as a robust screw pump seal, significantly reduces maintenance costs and unplanned downtime.

Unique Challenges of Marine Fuel and Lube Oil Transfer

Marine fuel and lube oil transfer systems face distinct challenges. These systems handle highly flammable liquids under varying conditions. Common causes of fuel sprays from low-pressure piping systems include using non-original parts, loose fittings, and incorrect assembly after maintenance. Vibrations can cause piping connections to loosen or pipes to fracture. The age of a ship increases fire risks, as machinery leakages become more frequent. Degradation of hot surface protection and cuts to maintenance budgets on older ships contribute to this risk. The transition between heavy fuel oil and marine gas oil is particularly vulnerable, with pressure fluctuations and thermal stress on aging seals leading to fires. Blocked drain lines can also create dangerous fuel accumulation points, increasing the risk of ignition.

Key Factors for Optimal Screw Pump Seal Selection

Fluid Compatibility and Material Matching for Screw Pump Seals

Selecting the correct materials for a screw pump seal is paramount. The seal's elastomers and faces must withstand the specific properties of marine fuel and lube oil. Incompatible materials can degrade rapidly, leading to leaks and premature seal failure. Engineers carefully match seal components to the fluid's chemical composition, ensuring long-term integrity and performance.

Operating Conditions: Temperature, Pressure, and Speed Considerations

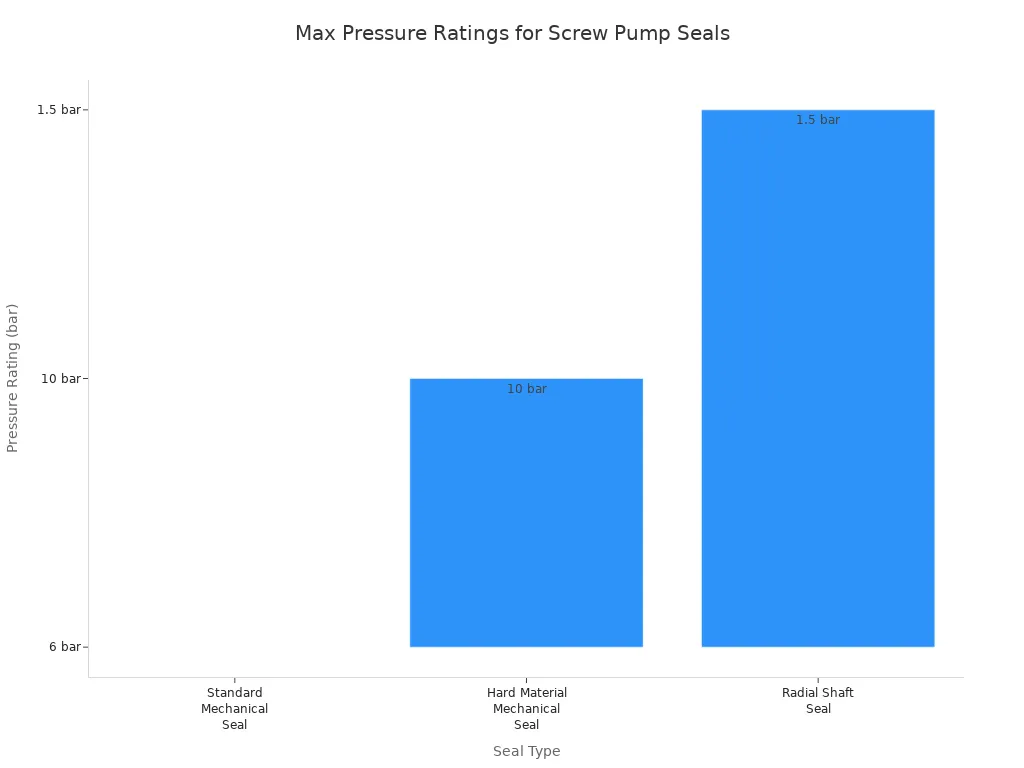

Operating conditions significantly influence seal choice. High temperatures can cause seal materials to soften or harden, compromising their sealing ability. Pressure ratings are also critical. Different seal types handle varying pressure levels effectively. For instance, a standard mechanical seal manages up to 6 bar, while a hard material mechanical seal can withstand 10 bar. Radial shaft seals are suitable for lower pressures, typically up to 1.5 bar. Rotational speed affects heat generation at the seal faces, impacting wear and overall seal life.

Environmental Factors: Abrasives, Corrosives, and Vibration

Marine environments present unique challenges. Abrasive particles, often present in fuel and lube oil, can wear down seal faces. Corrosive elements in the fluid or surrounding atmosphere attack seal materials, leading to degradation. Constant vibration from ship engines and machinery also stresses seals, potentially causing misalignment and early failure. A robust screw pump seal design accounts for these harsh conditions.

Pump Design and Configuration: Single vs. Double Screw Pump Seals

Pump design dictates the appropriate seal configuration. Single mechanical seals feature one set of primary sealing faces. They are simpler and cost less initially. Double mechanical seals, however, incorporate two sets of primary sealing faces and require a barrier fluid system. This design virtually eliminates process fluid leakage to the atmosphere, making them essential for hazardous or high-temperature fluids.

| Feature | Single Mechanical Seal | Double Mechanical Seal |

|---|---|---|

| Design | One set of primary sealing faces. | Two sets of primary sealing faces. |

| Barrier Fluid | Not required. | Requires a barrier fluid system (e.g., flush, quench, or buffer fluid). |

| Leakage | Minimal, controlled leakage of process fluid is expected. | Virtually zero process fluid leakage to the atmosphere. |

| Cost | Lower initial cost. | Higher initial cost due to the seal and barrier fluid system. |

| Complexity | Simpler design and installation. | More complex design, installation, and maintenance due to the barrier fluid system. |

| Safety | Suitable for non-hazardous or low-risk fluids. | Essential for hazardous, toxic, abrasive, or high-temperature fluids to prevent emissions. |

| Applications | General purpose pumps, water, oil, mild chemicals. | Chemical processing, pharmaceuticals, oil & gas, power generation, wastewater treatment, and applications with strict environmental regulations. |

| Lubrication | Lubricated by the process fluid itself. | Lubricated by the barrier fluid, which also cools the seal faces. |

| Environmental Impact | Potential for minor process fluid emissions. | Significantly reduces emissions, better for environmental compliance. |

| Maintenance | Generally simpler maintenance. | Requires maintenance of both the seal and the barrier fluid system. |

| Pressure/Temperature | Limited by process fluid characteristics. | Can handle higher pressures and temperatures due to barrier fluid cooling and lubrication. |

| Dry Running | Not suitable for dry running. | Some designs can tolerate brief periods of dry running with appropriate barrier fluid systems. |

| Reliability | Good for standard applications. | Enhanced reliability and extended lifespan in demanding applications due to better lubrication and cooling. |

Mechanical Seals: The Preferred Screw Pump Seal for Marine Applications

How Mechanical Seals Prevent Leaks: Precision and Durability

Mechanical seals represent the gold standard for preventing fluid leakage in demanding applications like marine fuel and lube oil transfer systems. They achieve this by creating a precise, controlled barrier between two highly engineered surfaces. One surface, the rotating face, attaches to the shaft and spins with it. The other surface, the stationary face, remains fixed to the pump housing. The primary sealing action occurs at the interface portion, the contact area where these two faces meet.

To maintain this critical interface, mechanical seals employ several key components. O-rings provide secondary sealing, preventing leakage between the stationary face and the housing, and between the rotating face and the shaft. Springs apply consistent pressure, keeping both primary faces pressed together. This constant contact is crucial for preventing leaks. For extended operation and minimal friction, a thin fluid film lubricates the faces. This film, typically around 3 micrometers thick, can be either a separate lubricant or the process fluid itself. It carries the load and prevents direct surface contact, which would otherwise lead to rapid wear and failure. This combination of precision engineering and durable materials ensures reliable, leak-free performance.

Advantages of Mechanical Screw Pump Seals: High Pressure, Low Leakage

Mechanical seals offer significant advantages in marine environments, making them the preferred choice for screw pumps. Their design allows them to handle high operating pressures effectively, a common requirement in fuel and lube oil transfer systems. They achieve exceptionally low leakage rates, often virtually eliminating fluid escape to the atmosphere. This minimizes environmental impact and enhances safety by containing flammable liquids. The robust construction of mechanical seals provides superior durability, resisting the harsh conditions found at sea, including temperature fluctuations, vibrations, and the abrasive nature of some fluids. Their reliability translates into reduced maintenance needs and extended operational periods, contributing to overall system efficiency.

Considerations for Mechanical Screw Pump Seals: Cost and Installation

While mechanical seals offer superior performance, their initial cost can be higher than simpler sealing solutions. However, their long-term benefits, such as reduced leakage, lower maintenance, and enhanced safety, often outweigh this initial investment. Proper installation is paramount for optimal performance and longevity. Installers must follow a systematic approach.

Before installation, technicians perform a thorough preparation and safety check. They ensure the work area is clean and safe, implementing lockout/tagout procedures. They carefully remove the old seal and inspect the shaft, sleeve, and housing for any damage. Cleaning all parts that will contact the new seal is essential. Technicians then inspect the new seal for defects and use precision measuring instruments, such as calipers and micrometers, to verify critical dimensions.

The installation process itself requires careful attention. Technicians apply a compatible lubricant to the seal components and slide the seal onto the shaft, ensuring correct orientation. They position the seal according to manufacturer specifications. Reassembly of other pump components follows, with careful attention to alignment. Technicians tighten fasteners to specified torque values. After installation, testing is crucial. This includes leak testing and a complete operational test, often involving a gradual increase in pressure and speed during startup. Tools like Allen wrenches, socket sets, torque wrenches, and seal installation tools are essential for this process. Adhering to manufacturer guidelines, including proper torque on all bolts and the correct order of assembly, ensures the seal functions as intended.

Real-World Application: Mechanical Screw Pump Seal in Fuel Transfer

Consider a large cargo vessel transferring heavy fuel oil from storage tanks to the engine's day tanks. This operation involves high volumes, significant pressures, and a highly flammable fluid. A robust screw pump seal is critical here. A mechanical seal, specifically designed for such conditions, ensures the integrity of the transfer system. It prevents any leakage of fuel oil, which could pose a severe fire hazard or environmental spill. The seal's ability to withstand the fuel's viscosity, temperature, and pressure variations guarantees continuous and safe operation. This application highlights how mechanical seals are not just components but vital safety and environmental guardians in the marine industry.

Other Screw Pump Seal Types and Their Suitability

Packing Seals (Gland Packing): Cost-Effectiveness vs. Leakage

Packing seals, also known as gland packing, represent a traditional sealing method. They offer a low initial cost. Installers wrap braided material around the pump shaft. This material compresses to create a seal. However, packing seals inherently require some leakage to lubricate and cool the packing material. This constant drip can lead to environmental concerns and product loss, especially with fuel and lube oil. They also demand frequent adjustment and replacement, increasing maintenance labor. Modern marine operations often find their leakage rates unacceptable.

Lip Seals: Limited Use for Fuel and Lube Oil Transfer

Lip seals are another type of dynamic seal. They feature a flexible lip that presses against a rotating shaft. This design creates a barrier. Manufacturers typically use rubber or similar elastomers for lip seals. They work well in low-pressure, low-speed applications. However, lip seals struggle with the high pressures, varying temperatures, and abrasive particles common in marine fuel and lube oil transfer. Their limited chemical compatibility with aggressive fluids also restricts their use in these demanding environments. They generally do not provide the robust, leak-free performance required for critical marine systems.

Specialized Screw Pump Seals: Bellows and Advanced Options

Beyond standard mechanical seals, other specialized options exist for unique challenges. Bellows seals, for instance, use a flexible metal or elastomer bellows to provide axial movement. This design eliminates dynamic secondary seals, which can wear over time. They offer excellent performance in high-temperature or corrosive applications. Advanced cartridge seals integrate all seal components into a single unit. This simplifies installation and reduces potential errors. These specialized seals address specific operational demands where conventional solutions may fall short. They provide enhanced reliability and extended service life in particularly harsh or critical scenarios.

Step-by-Step Guide to Selecting the Right Screw Pump Seal

Selecting the optimal screw pump seal requires a systematic approach. Engineers must consider various factors to ensure reliable, leak-free operation in marine environments. This guide outlines the essential steps for making an informed decision.

Assessing Specific Application Requirements for Screw Pump Seals

The first step involves a thorough assessment of the specific application. Engineers identify the fluid being pumped, noting its chemical composition, viscosity, and any abrasive particles present. They determine the operating temperature range, from minimum to maximum, and the system's pressure limits. The pump's rotational speed also plays a crucial role. Understanding these parameters helps narrow down suitable seal types and materials. For instance, a system handling highly viscous heavy fuel oil at high temperatures will demand different seal characteristics than one transferring lighter lube oil at lower pressures.

Evaluating Seal Material Compatibility for Fuel and Lube Oil

Material compatibility is paramount for seal longevity and performance. The seal's primary faces and secondary elastomers must resist chemical attack from the fuel or lube oil. Incompatible materials can swell, shrink, harden, or soften, leading to premature failure.

Tip: Always consult material compatibility charts provided by seal manufacturers. These charts detail how various elastomers and face materials react to different chemicals, including common marine fuels and lubricants.

Common materials for seal faces include silicon carbide, tungsten carbide, and carbon graphite. Elastomers like Viton, Kalrez, or EPDM offer resistance to specific chemicals and temperatures. Engineers select materials that can withstand the fluid's properties over the entire operating range.

Considering Screw Pump Seal Design and Configuration

The pump's design and the application's demands influence the seal configuration. Engineers choose between single and double mechanical seals based on safety, environmental regulations, and fluid characteristics. Single seals are suitable for less hazardous fluids where minor leakage is acceptable. Double seals, with their barrier fluid systems, provide superior containment for hazardous or environmentally sensitive fluids, virtually eliminating emissions. Cartridge seals offer ease of installation and maintenance, as they come pre-assembled and pre-set. This design reduces installation errors and simplifies replacement procedures.

Factoring in Maintenance and Lifecycle Costs of Screw Pump Seals

Beyond the initial purchase price, engineers must consider the long-term maintenance and lifecycle costs of a screw pump seal. A cheaper seal might lead to higher operational expenses due to frequent failures and downtime. Regular inspections are crucial for pump components, including alignment, bearings, and seals. Technicians recommend weekly checks for mechanical seals to detect leaks. Immediate action becomes necessary if leakage exceeds manufacturer specifications. Seals typically require replacement every 2-3 years. However, earlier replacement may be essential if leakage becomes unmanageable. Minor repairs, such as seal replacements, can cost a few hundred dollars. Major overhauls, including screw replacement or bearing work, can cost thousands of dollars. Labor costs represent a significant portion of the total repair expense. Always use manufacturer-approved parts for replacements to ensure proper fit and function. Investing in a high-quality, durable seal often reduces overall costs by extending service life and minimizing maintenance interventions.

Consulting Experts for Screw Pump Seal Selection

When facing complex applications or uncertainty, consulting seal experts provides invaluable guidance. Manufacturers like GW seal produce OEM products, including mechanical seals suitable for Allweiler screw pumps. These experts possess in-depth knowledge of seal technology, material science, and specific application challenges. They can recommend the most appropriate seal type, material combination, and configuration for unique operating conditions. Their expertise helps prevent costly mistakes, optimize performance, and ensure compliance with industry standards and regulations. Engaging with specialists ensures the selection of a robust and reliable sealing solution.

Best Practices for Screw Pump Seal Installation and Maintenance

Proper installation and diligent maintenance significantly extend the life and reliability of pump seals. Adhering to best practices prevents costly leaks and operational disruptions.

Proper Installation Techniques for Screw Pump Seals

Correct installation is crucial for seal performance. Technicians begin by ensuring the work area is clean and safe, implementing lockout/tagout procedures. They carefully remove the old seal and inspect the shaft and housing for damage. Thorough cleaning of all contact parts follows. Installers then inspect the new seal for defects and verify critical dimensions. During installation, they lubricate components and slide the seal assembly onto the shaft, ensuring correct orientation according to manufacturer specifications. Reassembly of pump components requires proper alignment and tightening fasteners to specified torque values. Common installation errors, such as uneven sealing surfaces, overtightening, or undertightening, can lead to premature failure.

Routine Inspection and Monitoring of Screw Pump Seals

Regular inspection helps detect potential issues early. Daily, operators should visually inspect seals and connections for any leaks. Weekly checks confirm seal integrity. Annually, maintenance schedules often include replacing bearings and seals to ensure a reliable system. Technicians should look for early warning signs of failure, such as deep grooves, uneven wear tracks, or fractured seal faces. These indicators suggest inadequate lubrication, abrasive materials, or improper installation.

Scheduled Maintenance and Replacement of Screw Pump Seals

Proactive maintenance extends seal life. Preventing dry running ensures seals remain lubricated, avoiding heat buildup and cracking. Operators should avoid excessive vibration by operating pump systems within their Best Efficiency Point (BEP). Using the correct lubrication film between seal faces minimizes wear and friction. Regular visual inspections for leakage and wear on seal faces are essential. Technicians also check the seal environment for cleanliness and verify cooling or flushing systems function correctly. Documenting all maintenance findings helps track performance and schedule future interventions.

Selecting the correct screw pump seal is crucial for preventing leaks in marine fuel and lube oil transfer systems. Mechanical seals offer robust solutions for demanding marine environments. Adhering to best practices in selection, installation, and maintenance ensures reliable, leak-free operation. Proactive seal management significantly contributes to operational efficiency and environmental compliance. This minimizes fluid leaks, reduces emissions, conserves water, and enhances energy efficiency.

FAQ

What makes mechanical seals the preferred choice for marine screw pumps?

- Mechanical seals offer high pressure handling, very low leakage, and superior durability. They ensure safety and environmental compliance in harsh marine environments.

What are the main disadvantages of using packing seals?

- Packing seals require constant leakage for lubrication. They also demand frequent adjustments and replacements, increasing maintenance and environmental concerns.

How often should technicians inspect screw pump seals?

- Operators should visually inspect seals daily. Technicians perform weekly checks for integrity. Annual maintenance schedules often include seal replacement.