How Cartridge Mechanical Seals Eliminate Costly Leaks

Cartridge Mechanical Seals, such as the AES CDSA, act as a powerful barrier against leaks in industrial settings. I find that these seals tackle the core issues causing leaks, which helps minimize disruptions in operations. By implementing these seals, businesses can achieve substantial cost savings and improve safety standards.

Key Takeaways

- Cartridge Mechanical Seals effectively prevent leaks, reducing downtime and maintenance costs in industrial operations.

- Proper installation and regular maintenance of these seals are crucial for optimal performance and long-term reliability.

- Implementing Cartridge Mechanical Seals enhances workplace safety by preventing hazardous leaks and improving operational efficiency.

Common Causes of Industrial Leaks

Industrial leaks often stem from several key issues that I have encountered in my experience.

Equipment Wear and Tear

Equipment wear and tear is a significant contributor to leaks. As machinery operates, components naturally degrade. The frequency and intensity of use can accelerate this process. For instance, when equipment runs continuously, parts wear down faster, increasing the risk of leaks. Additionally, the quality of materials plays a crucial role. Higher-quality components resist wear better, while cheaper alternatives may fail. Harsh operational environments, such as extreme temperatures or corrosive substances, further exacerbate wear and tear.

| Factor | Description |

|---|---|

| Frequency and intensity | The more often equipment is used, the quicker its components wear down, increasing leak risks. |

| Material quality | Higher quality materials resist wear better, while cheaper parts may fail and cause leaks. |

| Operational environment | Harsh conditions like extreme temperatures or corrosive substances accelerate wear and tear. |

Improper Installation

Improper installation is another common cause of leaks. I have seen firsthand how human error can lead to significant issues. For example, using inappropriate tools can damage seal surfaces, while selecting the wrong size or type of seal can prevent proper functioning under pressure. Poor installation practices often result in misalignment, leading to premature wear and leakage.

Environmental Factors

Environmental factors also play a critical role in the integrity of mechanical seals. Temperature fluctuations can severely impact seal performance. For instance, cold temperatures can make O-ring materials stiff and brittle, leading to cracking. On the other hand, high humidity can cause O-rings to swell, compromising their fit. Continuous exposure to moisture accelerates degradation, resulting in loss of elasticity and surface cracking.

- Cold temperatures can make O-ring materials stiff and brittle, leading to cracking and failure.

- High humidity can cause O-rings to swell, compromising their fit and leading to leaks.

- Continuous moisture exposure accelerates degradation, resulting in loss of elasticity and surface cracking.

By understanding these common causes, I can better appreciate how Cartridge Mechanical Seals can effectively mitigate these risks and enhance operational reliability.

How Cartridge Mechanical Seals Address Leak Issues

Cartridge Mechanical Seals effectively tackle leak issues through their innovative design features, simplified installation process, and proactive maintenance advantages. I have observed how these elements contribute to enhanced reliability in various industrial applications.

Design Features

The design of Cartridge Mechanical Seals plays a crucial role in preventing leaks, especially in high-pressure environments. Here are some key design features that I find particularly effective:

| Design Feature | Description |

|---|---|

| Advanced Sealing Technologies | These seals incorporate precision-engineered seal faces that maintain contact through calibrated spring forces. |

| Face Geometry | Optimized through computational fluid dynamics, this feature promotes stable operation and minimizes heat generation. |

| Advanced Seal Face Designs | Some designs include spiral grooves or textured surfaces to enhance lubrication and heat dissipation. |

| Secondary Sealing System | Multiple barriers like O-rings or gaskets prevent leakage along static interfaces. |

| Dual Seal Configurations | These configurations provide redundant sealing protection for critical applications. |

| Barrier Fluid System | Customized systems provide lubrication, cooling, and contamination protection for seal faces. |

| Monitoring Capabilities | Integrated systems offer real-time feedback on seal condition and performance. |

These features ensure that Cartridge Mechanical Seals can withstand aggressive chemicals, high pressure, and extreme temperatures, making them superior to traditional sealing solutions.

Installation Benefits

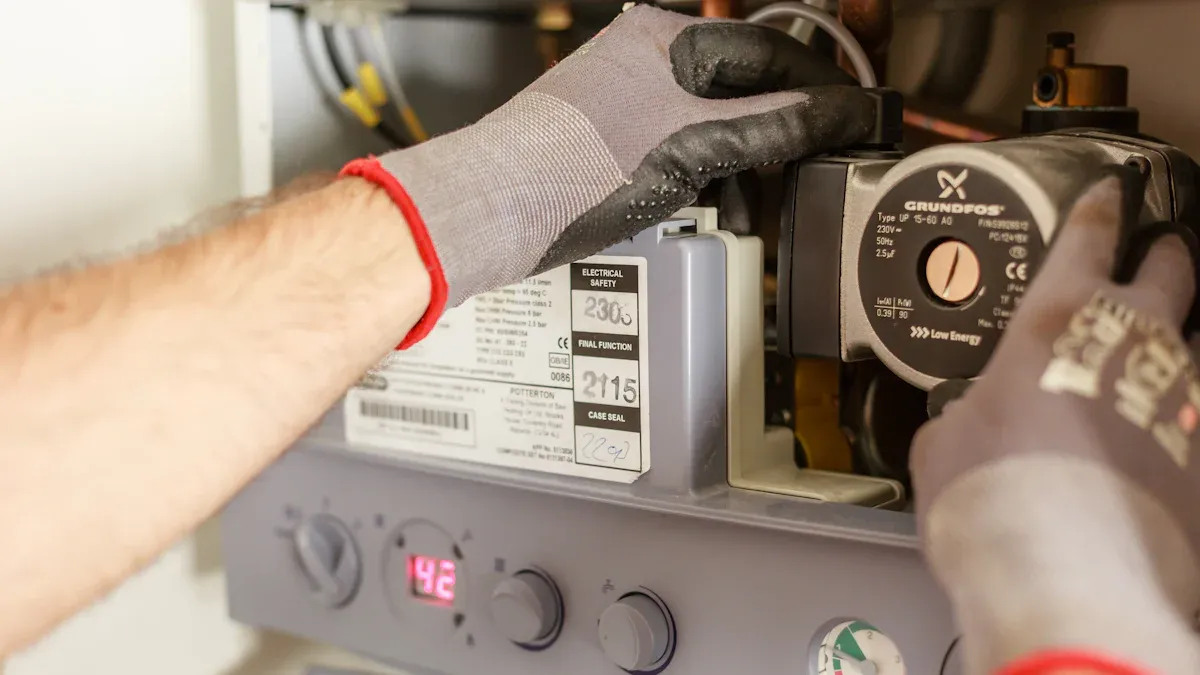

I appreciate the user-friendly nature of Cartridge Mechanical Seals. Their pre-assembled design simplifies the installation process significantly. Here are some benefits I have noted:

- Cartridge seals require minimal assembly expertise, ensuring proper alignment.

- The factory assembly and testing enhance reliability, reducing the risk of installation errors.

- Unlike traditional seals, which necessitate careful alignment of various components, cartridge seals save time and reduce assembly errors.

This ease of installation is crucial for maintaining productivity in industrial settings. It allows technicians to focus on other essential tasks rather than spending excessive time on complex assembly processes.

Maintenance Advantages

Maintaining Cartridge Mechanical Seals is straightforward, which is vital for long-term leak prevention. Here are some recommended maintenance practices that I have found effective:

| Maintenance Practice | Description |

|---|---|

| Proper Installation | Ensures that the seal is correctly positioned to prevent leaks. |

| Periodic Maintenance | Involves monitoring seal wear and replacing worn components to maintain performance. |

| Regular Inspection | Helps identify early signs of wear to address issues before they escalate. |

| Lubrication Maintenance | Maintains the fluid film between seal faces to reduce heat and friction. |

| Dry Run Monitoring | Installing a monitor prevents operation without sufficient fluid, which can damage the seal. |

Regular inspection and monitoring are essential for identifying early signs of wear. Addressing potential issues proactively can prevent significant problems from developing. Effective lubrication is crucial for reducing heat and friction between seal faces, ensuring optimal performance.

Benefits of Using Cartridge Mechanical Seals

Cartridge Mechanical Seals offer numerous advantages that can significantly enhance operational efficiency and safety in industrial settings. I have seen firsthand how these benefits translate into tangible improvements for businesses.

Cost Savings

One of the most compelling reasons to adopt Cartridge Mechanical Seals is the substantial cost savings they provide. These seals minimize downtime and reduce maintenance expenses, which are critical factors in any industrial operation.

- Simplified Installation: Cartridge seals come pre-assembled, which reduces installation time and errors. This efficiency allows technicians to focus on other essential tasks.

- Reduced Maintenance Needs: Engineered for minimal maintenance, these seals lead to fewer interventions and lower costs. I have observed that companies using cartridge seals experience a significant decrease in maintenance frequency.

- Quick Replacement: The ability to replace cartridge seals as complete units minimizes downtime during maintenance. This feature is crucial for maintaining productivity.

| Aspect | Description |

|---|---|

| Simplified Installation | Cartridge seals arrive pre-assembled, reducing installation time and errors. |

| Reduced Maintenance Needs | Engineered for minimal maintenance, leading to fewer interventions and lower costs. |

| Quick Replacement | Can be replaced as complete units, minimizing downtime during maintenance. |

By effectively preventing fluid or gas leakage, cartridge seals ensure that the media being processed remains contained. This design not only improves operational performance but also reduces the need for frequent maintenance associated with traditional seals, thereby lowering overall operational costs.

Safety Improvements

Safety is paramount in any industrial environment, and Cartridge Mechanical Seals play a vital role in enhancing workplace safety. I have witnessed how their implementation leads to significant improvements in safety standards.

- Early Detection Systems: The use of condition monitoring systems allows for early detection of potential seal failures. This early detection reduces the risk of hazardous leaks and minimizes the chances of sudden equipment breakdowns.

- Prevention of Toxic Leaks: Mechanical seals are fundamental in preventing leaks that could compromise safety in hazardous environments. They help avoid dangerous scenarios such as fires and explosions, protecting worker health.

| Risk | Consequence |

|---|---|

| Chemical Leaks | Can lead to serious health hazards and environmental contamination. |

| Equipment Malfunction | Seal failures can cause unplanned shutdowns and expensive repairs, impacting operational efficiency. |

| Worker Safety Concerns | Exposure to hazardous chemicals can result in severe injuries and long-term health issues. |

By preventing leaks and emissions, cartridge seals assist industries in meeting stringent environmental regulations and sustainability goals. Their reliable performance contributes to a safer working environment, which is essential for both employees and the surrounding community.

Case Studies of Successful Implementations

I find that real-world examples often illustrate the effectiveness of Cartridge Mechanical Seals best. Here are some notable case studies demonstrating their impact:

| Industry | Case Study Description | Results |

|---|---|---|

| Chemical Processing | A chemical manufacturing company faced frequent seal failures in high-pressure reactors. | Reduced maintenance costs by 40% after switching to dual mechanical seals with cooling jackets. |

| Oil and Gas | An oil refinery had issues with traditional packing seals in crude oil pumps. | Achieved a 50% reduction in unplanned shutdowns with metal bellows mechanical seals. |

| Power Generation | A thermal power plant experienced frequent seal leaks in cooling water pumps. | Implemented cartridge seals that provided leak-free operation for over 18 months. |

| Wastewater Treatment | XYZ Treatment Plant replaced traditional seals with cartridge type mechanical seals. | Significant reduction in leaks and maintenance costs, ensuring consistent treatment process. |

| Wastewater Treatment | ABC Municipal Plant adopted cartridge type mechanical seals to contain contaminants. | Effectively prevented environmental damage and reduced maintenance needs. |

These case studies highlight the versatility and effectiveness of Cartridge Mechanical Seals across various industries. They not only improve operational efficiency but also contribute to significant cost savings and enhanced safety.

Cartridge Mechanical Seals are vital for preventing costly leaks in industrial settings. Their innovative design and straightforward installation significantly reduce leak risks. I believe adopting these seals represents a proactive approach to enhancing operational efficiency and safety. Industries can enjoy long-term benefits, including lower maintenance costs and improved reliability.

FAQ

What are Cartridge Mechanical Seals?

Cartridge Mechanical Seals are pre-assembled sealing devices designed to prevent leaks in rotating equipment, ensuring reliable operation in various industrial applications.

How do I know if my seals need replacement?

I recommend monitoring for leaks, unusual noises, or vibrations. Regular inspections can help identify wear and determine if replacement is necessary.

Can Cartridge Mechanical Seals be used in all industries?

Yes, Cartridge Mechanical Seals are versatile and suitable for various industries, including oil and gas, chemical processing, and wastewater treatment. They effectively handle diverse media and conditions.