How to Safeguard Your Petrochemical Plant from Seal Failures

2025-10-23

Seal failures critically impact petrochemical plant safety and profitability, causing significant operational disruptions. Proactive prevention is essential for maintaining operational continuity. Downtime analysis reveals that issues like high pressure overload account for 30% of failures, und...

view

detail

How to Choose the Best Slurry Seals to Boost Mining Bottom Lines

2025-10-21

Inadequate slurry seals create significant financial drains for mining operations. One specific operation faced annual losses exceeding $1.2 million due to frequent failures. Optimal slurry seal performance directly boosts operational profitability. Strategic mining seal selection is critical t...

view

detail

Leak-free Solution: Double Cartridge Mechanical Seal in Pulp and Paper

2025-10-17

Double Cartridge Mechanical Seals are the definitive answer for leak-free operations in the pulp and paper industry. They offer an optimal strategy for demanding environments. The financial impact of leakage in this sector is significant. For instance, profit shifting in Indonesia's pulp sector...

view

detail

How to Ensure Product Integrity Through Proper Sanitary Mechanical Sealing

2025-10-15

Product integrity in hygienic environments is paramount. Contamination fundamentally threatens product quality and consumer safety. Proper sanitary mechanical sealing provides a critical barrier against these risks. This essential component ensures products remain pure and effective. Businesses...

view

detail

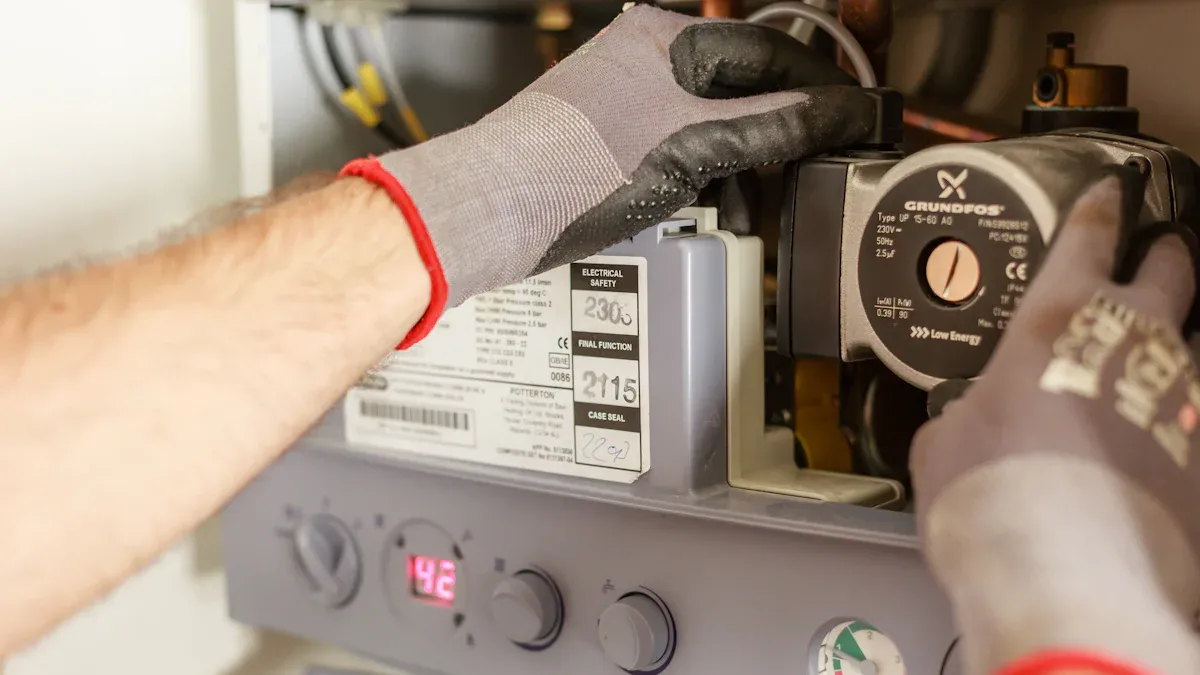

Stop Grundfos Seal Leaks Proven Strategies for Chemical Plants

2025-10-13

Chemical plants face critical challenges from Grundfos pump seal failures. These failures severely impact safety and operational continuity. Mechanical seal failures cause approximately 40% of all unscheduled critical pump shutdowns. They represent the second most common pump issue, accoun...

view

detail

How to Troubleshoot Common Dewatering Pump Seal Issues in Mining

2025-10-09

Dewatering pump seals play a crucial role in mining operations. They prevent leaks that can disrupt processes and compromise safety. Issues with the mining pump seal, such as wear and tear, can significantly impact operational efficiency. Addressing these common problems is essential for mainta...

view

detail

Solving Misalignment Issues to Prevent Slurry Pump Seal Failures

2025-10-08

Preventing misalignment in slurry pumps is crucial for maintaining operational efficiency. Misalignment directly leads to slurry pump seal failures, compromising equipment integrity. Mining operations must adopt proactive measures to ensure proper alignment of the slurry pump seal, safeguarding...

view

detail

Ensuring Hygienic Integrity in Food Production: A Centrifugal Pump Seal Solution

2025-10-07

Centrifugal pump seals are essential in food production, ensuring reliability that is vital for maintaining product quality. By preventing leaks and contamination, these seals enhance operational efficiency. The OEM mechanical seal, specifically designed for APV pump seal applications, exe...

view

detail

Solution for low-temperature environments: GW 687 Metal Bellows Seal

2025-10-03

The GW 687 metal bellows seal features a unique design and high-quality materials, making it perfect for low-temperature environments. Its fully metallic construction eliminates failures associated with dynamic elastomers, ensuring reliable operation. Performance metrics indicate that the GW 68...

view

detail

How Metal Bellows Seal Solves Crude Oil Sealing Issues

2025-10-01

Metal bellows seals provide a reliable solution for sealing challenges in crude oil applications. These metal bellow seals excel in preventing leaks and ensuring system integrity in harsh environments. Their unique design and functionality, including features of high temperature mechanical seal...

view

detail