MG1 Bellow Mechanical Shaft Seal for Water Pump MG12 MG13 MGS20

Industrial Sealing Solutions:

This robust elastomer bellow mechanical seal is engineered for medium to heavy-duty applications involving variable pressure conditions. It delivers reliable performance across a broad spectrum of industries, including:

• Chemical pump seals and agitator seal systems

• Pulp and paper stock processing equipment

• Wastewater treatment pump and mixer applications

• General industrial rotary lobe pump seal and centrifugal pump seal replacements

Product Detail

Innovative Upgrade: eMG1 Series Seal (Please contact us for more information~)

100% Compatibility: The eMG1 is fully interchangeable with the widely adopted MG1 standard seal in dimensions and interfaces, enabling direct replacement without modifying existing equipment.

Detailed Innovations: Optimized bellows root geometry reduces stress concentration and extends fatigue life; spring surfaces feature enhanced corrosion-resistant coating for improved reliability in humid or corrosive environments.

Functional Expansion: Optional high-performance material combinations (e.g., SiC/SiC faces) increase the maximum pressure rating to 1.8 MPa and temperature range to -50°C ~ 200°C, suiting more demanding applications.

Equivalent Products

• Vulcan®: Type 19/192/193

• JohnCrane®: Type MG1/MG12/MG13/S20

• Roten®: Type L3/L3K

• Lidering Seal®: Type LRB17/107 L4

• Flowserve Pac. seal®: Type 190/192/193

• Sterling®: Type SMG1

• M.T.U.®: FG 1

• U.S. Seal®: Type VGMC-1

Our OEM mechanical seal products provide direct replacements for the above-listed models, offering high-quality mechanical seal performance under ISO 9001-certified manufacturing, with cost-efficient pricing for pump seal replacement needs.

Material and Operating Range

Material:

• Rotary ring: Carbon/SiC/TC

• Stationary ring: 99% Alumina Ceramic mechanical seal face /SiC/TC

• Elastomer: VITON, NBR, or EPDM O-rings and seals

• Metal Parts: SUS304/SUS316 Stainless Steel

* Custom material and configuration options are available upon request for specialized mechanical seal solutions.

Operating Parameters:

• Temperature: -40 ℃ to 180 ℃ (high-temperature mechanical seal capability)

• Pressure: ≤ 1.5 MPa

• Speed: ≤ 10 m/s

• Suitable Media: Oils, water, sewage, paper pulp slurries, and a wide range of chemical mechanical seal applications

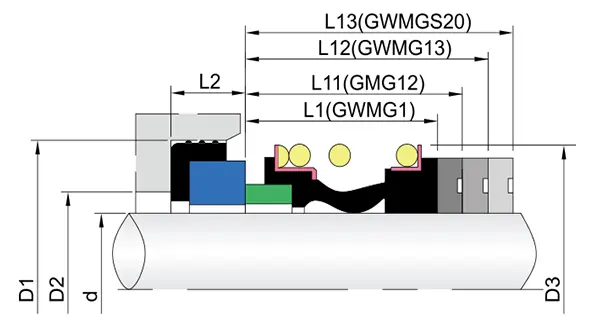

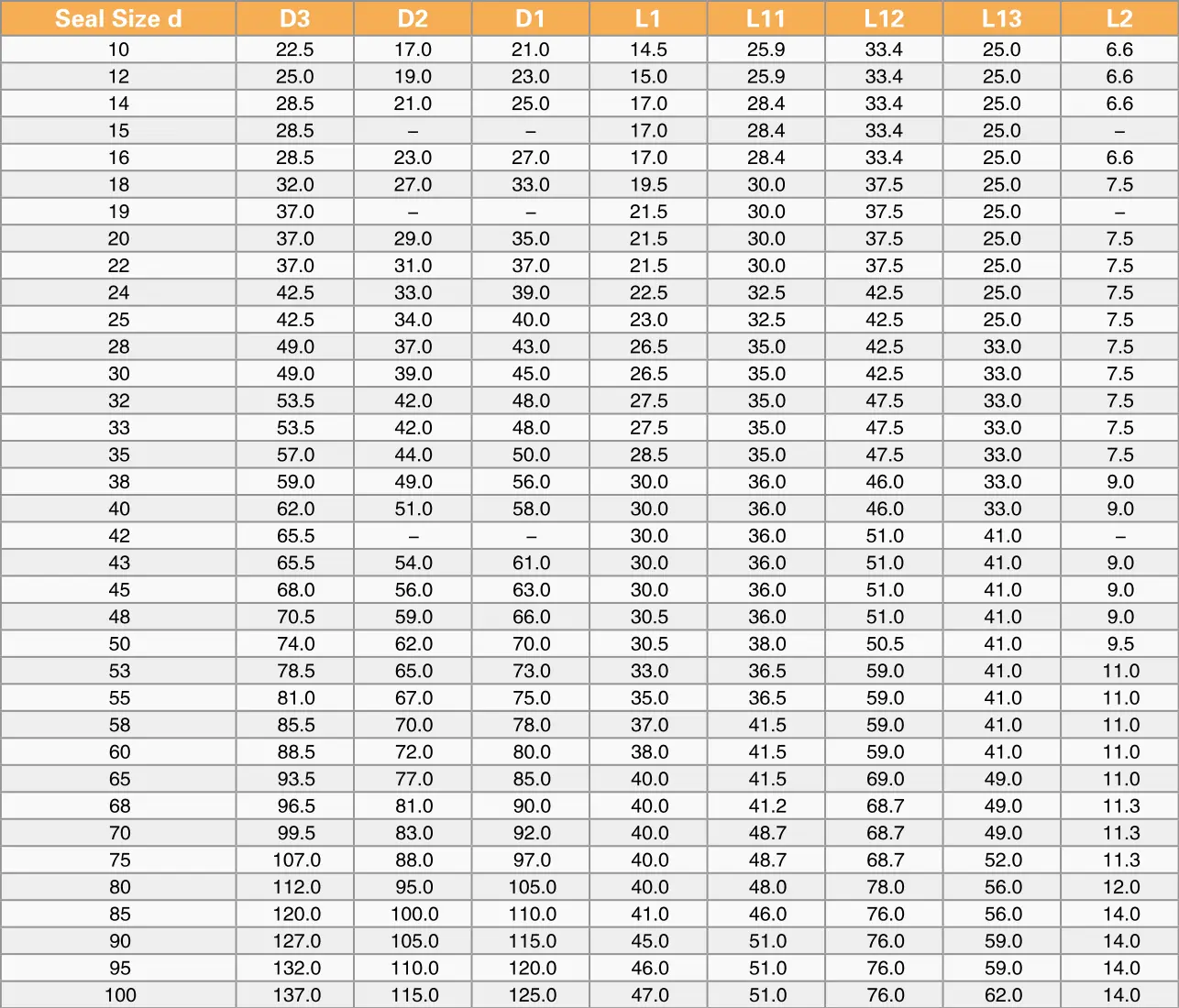

Installation Dimensions

description2