Metric Multi Spring Balanced PTFE Seal 59B Replacement

This EN 12756 mechanical seal delivers high-performance shaft sealing for metric stepped shafts in demanding heavy-duty applications:

• Petrochemical processing seals (oil refining, chemical plants)

• Pharmaceutical agitator seals (FDA certified material required)

• Chemical pump mechanical seals - Acid transfer seals with ≤6MPa capability

• Power generation shaft seals - Boiler feed water pumps at 25m/s

• Pulp & paper stock seals - Abrasion-resistant for 15% fiber slurries

Product Detail

• PTFE wedge mounting: Chemical-resistant material ensures media integrity and secure installation

• Multi-spring mechanism: Precision springs distribute load evenly and ensures uniform face pressure

• Hex-key tightened set screws for positive shaft drive

• Step-shaft optimization: Metric stepped shafts 18-120mm range and leads to higher sealing performance

• Narrow Radial Profile: Space-saving for compact seal chamber

The narrow-designed radial profile is DIN 24960 / EN 12756 compliant, which is suitable for European metric seal chamber.

Equivalent Products

• Vulcan®: 1659B

• JohnCrane®: 59B

• Sterling®: 259B

*Certified ISO9001 multi-spring seals with identical dimensions at competitive prices.

Material and Operating Range

Material:

• Rotary ring: Carbon/Silicon Carbide/Tungsten Carbide

• Stationary ring: 99%Ceramic/ Silicon Carbide/Tungsten Carbide

• Sealing elements (O-ring): VITON/NBR/EPDM

• Metal components: SUS304/SUS316 stainless steel

Our engineering team provides tailored configurations for specialized applications: Material upgrades / Dual-seal conversions / Certified material kits / Non-standard dimensions.

Contact us to discuss your specific sealing requirements!

Operating Range:

• Temperature: -40 ℃~230℃(thermal shock resistant)

• Pressure: ≤6MPa (900 psi heavy-duty)

• Speed: ≤25m/s

• Performance: Wear

Compatible Media:

• Crude & refined oils

• Process water & sewage

• Alkali, salt, and other organic solvents.

• Pharmaceutical suspensions

• Paper and pulp (15% solids)

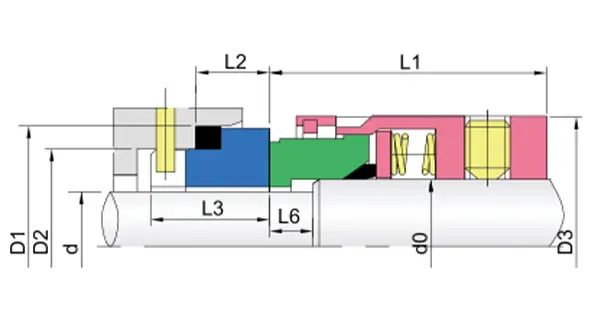

Installation Dimensions

| Size (Metric) | d0 | d | D3 | D2 | D1 | L1 | L2 | L3 | L6 |

| 14 | 18.0 | 14.0 | 32.0 | 21.0 | 25.0 | 30.5 | 12.0 | 18.5 | 6.0 |

| 16 | 20.0 | 16.0 | 34.0 | 23.0 | 27.0 | 30.5 | 12.0 | 18.5 | 6.0 |

| 18 | 22.0 | 18.0 | 36.0 | 27.0 | 33.0 | 31.5 | 13.5 | 20.5 | 6.5 |

| 20 | 24.0 | 20.0 | 38.0 | 29.0 | 35.0 | 31.5 | 13.5 | 20.5 | 6.5 |

| 22 | 26.0 | 22.0 | 40.0 | 31.0 | 37.0 | 31.5 | 13.5 | 20.5 | 6.5 |

| 24 | 28.0 | 24.0 | 42.0 | 33.0 | 39.0 | 34.2 | 13.3 | 20.3 | 6.7 |

| 25 | 30.0 | 25.0 | 44.0 | 34.0 | 40.0 | 34.5 | 13.0 | 20.0 | 7.0 |

| 28 | 33.0 | 28.0 | 47.0 | 37.0 | 43.0 | 37.5 | 12.5 | 19.5 | 7.5 |

| 30 | 35.0 | 30.0 | 49.0 | 39.0 | 45.0 | 38.0 | 12.0 | 19.0 | 8.0 |

| 32 | 38.0 | 32.0 | 54.0 | 42.0 | 48.0 | 38.0 | 12.0 | 19.0 | 8.0 |

| 33 | 38.0 | 33.0 | 54.0 | 42.0 | 48.0 | 38.0 | 12.0 | 19.0 | 8.0 |

| 35 | 40.0 | 35.0 | 56.0 | 44.0 | 50.0 | 38.0 | 12.0 | 19.0 | 8.0 |

| 38 | 43.0 | 38.0 | 59.0 | 49.0 | 56.0 | 39.5 | 13.0 | 20.0 | 10.0 |

| 40 | 45.0 | 40.0 | 61.0 | 51.0 | 58.0 | 39.5 | 13.0 | 20.0 | 10.0 |

| 43 | 48.0 | 43.0 | 64.0 | 54.0 | 61.0 | 39.5 | 13.0 | 20.0 | 10.0 |

| 45 | 50.0 | 45.0 | 66.0 | 56.0 | 63.0 | 39.5 | 13.0 | 20.0 | 10.0 |

| 48 | 53.0 | 48.0 | 69.0 | 59.0 | 66.0 | 39.5 | 13.0 | 20.0 | 10.0 |

| 50 | 55.0 | 50.0 | 71.0 | 62.0 | 70.0 | 44.0 | 13.5 | 20.5 | 11.5 |

| 53 | 58.0 | 53.0 | 78.0 | 65.0 | 73.0 | 44.0 | 13.5 | 20.5 | 11.5 |

| 55 | 60.0 | 55.0 | 80.0 | 67.0 | 75.0 | 44.0 | 13.5 | 20.5 | 11.5 |

| 58 | 63.0 | 58.0 | 83.0 | 70.0 | 78.0 | 49.0 | 13.5 | 20.5 | 11.5 |

| 60 | 65.0 | 60.0 | 85.0 | 72.0 | 80.0 | 49.0 | 13.5 | 20.5 | 11.5 |

| 63 | 68.0 | 63.0 | 88.0 | 75.0 | 83.0 | 49.0 | 13.5 | 20.5 | 11.5 |

| 65 | 70.0 | 65.0 | 90.0 | 77.0 | 85.0 | 49.0 | 13.5 | 20.5 | 11.5 |

| 70 | 75.0 | 70.0 | 95.0 | 83.0 | 92.0 | 55.5 | 14.5 | 21.5 | 13.5 |

| 75 | 80.0 | 75.0 | 104.0 | 88.0 | 97.0 | 55.5 | 14.5 | 21.5 | 13.5 |

| 80 | 85.0 | 80.0 | 109.0 | 95.0 | 105.0 | 55.0 | 15.0 | 22.0 | 13.0 |

| 85 | 90.0 | 85.0 | 114.0 | 100.0 | 110.0 | 60.0 | 15.0 | 22.0 | 13.0 |

| 90 | 95.0 | 90.0 | 119.0 | 105.0 | 115.0 | 60.0 | 15.0 | 22.0 | 13.0 |

| 95 | 100.0 | 95.0 | 124.0 | 110.0 | 120.0 | 60.0 | 15.0 | 22.0 | 13.0 |

| 100 | 105.0 | 100.0 | 129.0 | 115.0 | 125.0 | 60.0 | 15.0 | 22.0 | 13.0 |

description2