Metal Bellow shaft Seals replace John Crane 609

This robust sealing solution excels in high-temperature industrial processes, including hot hydrocarbon systems, chemical processing pumps, and heat transfer fluid applications. Its advanced metal bellows design ensures consistent performance under extreme thermal and chemical conditions.

Product Detail

The GW 688 replaces conventional pusher seals by incorporating a durable edge-welded metal bellows that eliminates dynamic elastomers, providing superior resistance to chemical attack and thermal degradation. The bellows assembly transmits torque directly through its welded plates, maintaining precise face loading while compensating for shaft misalignment, wear, and thermal expansion.

This balanced seal design features a stationary bellows configuration that minimizes flexural stress during operation, significantly extending service life in high-speed applications. The innovative notch geometry and drive band mechanism distribute mechanical loads evenly, preventing stress concentration and protecting shaft components from wear. The seal complies with international dimensional standards including EN 12756 (DIN 24960) for broad interchangeability.

Equivalent Products

*Our ISO9001-certified manufacturing guarantees identical dimensional specifications and performance characteristics to the referenced OEM products, providing a reliable alternative with verified compatibility.

Material and Operating Range

Material:

• Rotary Ring: Carbon / Silicon Carbide (SiC) / Tungsten Carbide (TC)

• Stationary Ring: 99% Ceramic / SiC / TC

• Metal Bellows: AM350 Stainless Steel (double-ply design for high-pressure applications)

• Secondary Sealing: VITON / EPDM / Encapsulated Rings

• Metallic Components: SUS304 / SUS316

* Custom material configurations including alternative bellows alloys (e.g., Alloy 718) and specialized face materials are available for unique operating conditions.

Operating Range:

•Temperature Range: -75 ℃ to 400℃ (compatible with high-temperature hydrocarbons and thermal fluids)

• Pressure Limit: 2.5 MPa (single-ply bellows)

• Maximum Surface Speed: 25 m/s

Mediums:

• Crude oil fractions and refined petroleum products

• Process water, wastewater, and chemical solutions

• Aromatic hydrocarbon streams and heat transfer fluids

• Pulp and paper processing media

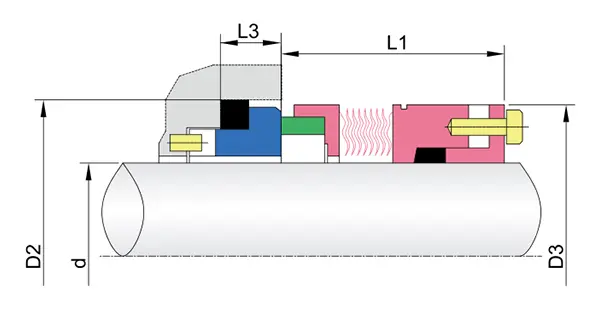

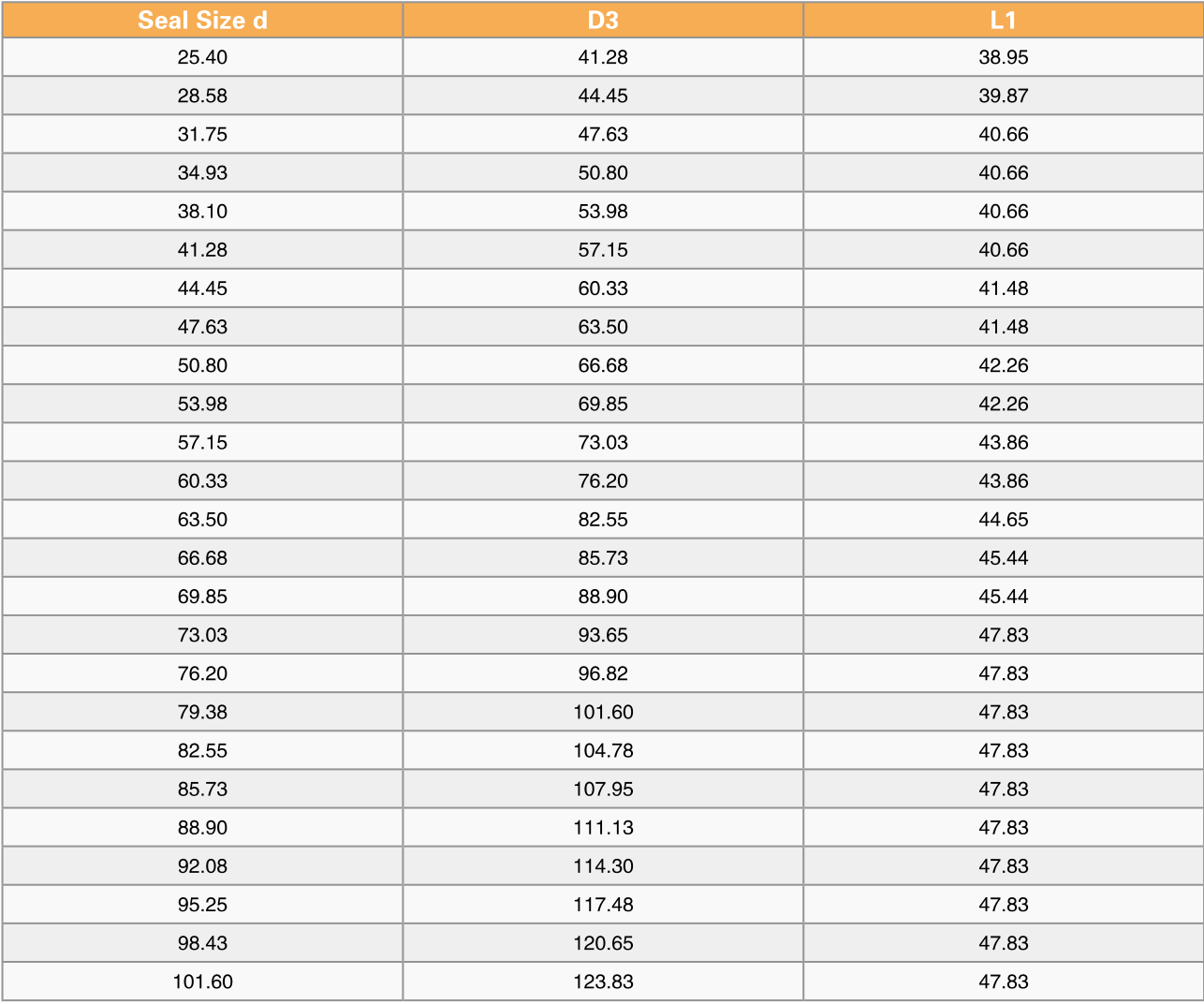

Installation Dimensions

description2