Wholesale Mechanical Seals for Abrasive Media - Trusted Suppliers and Manufacturers

When searching for a dependable Mechanical Seal for Abrasive Media, quality and durability are paramount. At Ningbo Guowei Mechanical Seals Co., Ltd., we specialize in crafting high-performance mechanical seals designed for challenging environments. Our products excel in withstanding demanding conditions, ensuring that your machinery operates efficiently and reliably. We provide competitive wholesale pricing, allowing businesses of all sizes to access superior seals without financial strain. Our comprehensive price list features various options tailored to meet your specific needs. With a strong focus on quality assurance, we guarantee that every mechanical seal adheres to the highest industry standards. Choose us for your mechanical seal requirements and benefit from exceptional reliability and service. Keep your operations running seamlessly!In-Depth Analysis of Methods Mechanical Seal for Abrasive Media Factory-Direct Excellence Service

In today's competitive landscape, the effectiveness of mechanical seals, particularly for abrasive media applications, cannot be overstated. These seals play a crucial role in ensuring the integrity of machinery and systems by preventing leaks and protecting equipment from contaminants. Advanced mechanical seal technology not only enhances operational efficiency but also significantly reduces maintenance costs and downtime, making it essential for manufacturers to invest in high-quality solutions. An in-depth analysis of the various methods available for mechanical seals reveals the critical factors that global buyers should consider when sourcing these components. Factors such as material compatibility, seal design, and the specific environment in which they will be used can greatly influence performance and longevity. Manufacturers need to prioritize seals that utilize durable materials engineered to withstand harsh conditions, especially in abrasive media applications. Furthermore, customization options can also help tailor solutions to unique operational requirements, thus optimizing performance. As businesses continue to expand their global footprint, the importance of a reliable supplier becomes paramount. Partnering with an experienced manufacturer that offers not only high-quality products but also responsive service can facilitate smoother operations and foster long-term success. Global buyers are encouraged to look for suppliers that understand the challenges faced in abrasive environments and can provide innovative solutions to enhance productivity and reduce risks associated with leakage and wear.

In-Depth Analysis of Methods Mechanical Seal for Abrasive Media Factory-Direct Excellence Service

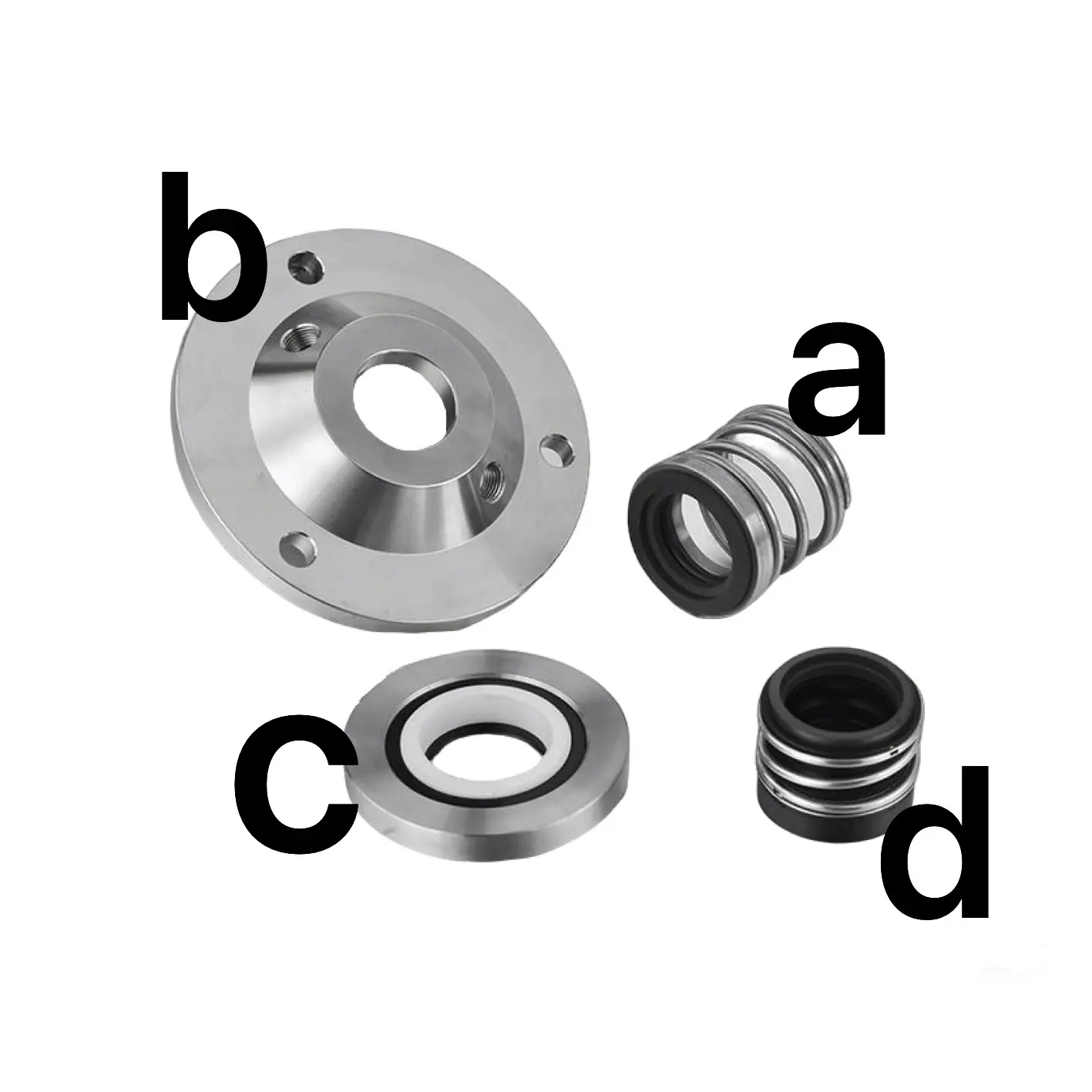

| Sealing Method | Material Compatibility | Operating Temperature (°C) | Pressure Rating (bar) | Applications | Advantages |

|---|---|---|---|---|---|

| Single Spring Mechanical Seal | Carbon, Silicon Carbide | -20 to 200 | 10 | Pumps, Compressors | Simple design, Cost-effective |

| Balanced Mechanical Seal | Stainless Steel, PTFE | -30 to 150 | 16 | Chemical Processing | Good performance under pressure |

| Double Mechanical Seal | Tungsten Carbide, Elastomer | -40 to 200 | 25 | Oil & Gas, Water Treatment | High reliability, Reduced leakage |

| Spring-less Mechanical Seal | Ceramics, Fluorocarbon | -50 to 300 | 30 | Pharmaceutical Industry | Low maintenance, High performance |

Trending Mechanical Seal for Abrasive Media Ahead of the Curve Guarantees Peak Performance

K

Kevin Hall

The durability of this product is impressive! The service team went above and beyond to ensure my satisfaction.

29 June 2025

O

Olivia Robinson

Remarkable product quality! The support team was very skilled and addressed all my queries with excellence.

03 June 2025

C

Chloe Lee

The quality of this product is outstanding! The customer support team was professional and addressed my concerns promptly.

29 June 2025

N

Natalie Phillips

Remarkable quality! I was impressed by how professional and understanding the after-sales team was.

16 May 2025

R

Rachel Rivera

Incredible craftsmanship and quality! Customer support was very helpful and professional throughout.

26 June 2025

C

Connor Martinez

Outstanding quality! The support I received after purchase was professional and efficient.

28 June 2025