Materials and FeaturesGW SEAL Technical Reference Guide

GW SEAL provides a variety of seal materials for different operating conditions. Selecting the right material for mechanical seals ensures optimal performance, durability, and cost-effectiveness in diverse operating conditions. Below is a guide to common materials used in mechanical seals and their key characteristics to help you choose the best option for your applications.

Tungsten Carbide (WC)

- Features :

-

High toughness and wear resistance.

High thermal conductivity and low thermal expansion.

Available in nickel- or cobalt-bonded grades for varying corrosion resistance.

- Applications :

-

Mining, slurry pumps, and wastewater treatment.

Moderate chemical exposure.

-

Temperature Range: -200°C to 800°C.

Hardness:1,400–1,800 HV.

Brand No. |

YG6 |

YG8 |

YG15 |

YGN8 |

Density |

14.6-15.0 |

14.5-14.9 |

13.9-14.2 |

14.4-14.8 |

HRA |

89.5 |

89 |

87 |

88 |

Bending Strength |

1421 |

1470 |

2058 |

1470 |

Linear Expansivity (10-6/k(20C-500C) |

5 |

5.1 |

6.3 |

5.3 |

Medium |

Resistant against: Oil, sewage water, weak acid/alkali etc. |

Strong corrosive medium |

||

Silicon Carbide (SiC)

- Features :

-

Exceptional hardness and wear resistance.

High thermal conductivity and resistance to thermal shock.

Excellent chemical inertness (resists acids, alkalis, and abrasives).

- Applications :

-

High-speed, high-pressure environments (e.g., chemical pumps, oil refineries).

Abrasive or corrosive media.

-

Temperature Range: -100°C to 1,400°C (limited by secondary materials).

Hardness:2,500–2,800 HV.

unit |

Reaction Silicon Carbide SiC |

Sintered Silicon Carbide |

|

Purity |

% |

≧90 |

≧98 |

Density |

g/cm3 |

3.05 |

3.1 |

Shore Hardness |

HS |

110-125 |

120-130 |

Elastic Modulus |

MPa |

4.12*105 |

4.12*105 |

Tensile Strength |

MPa |

2.75*102 |

2.8*102 |

Bending Strength |

MPa |

4.41*102 |

4.9*102 |

Compression Strength |

MPa |

2.94*103 |

3.0*103 |

Thermal Conductivity |

W/mK |

141 |

147 |

Coefficient of Thermal Expansion |

I/℃ |

4.3*10-6 |

4.0*10-6 |

Heat Resistance |

℃ |

1600 |

1650 |

Thermal Impact Coefficient |

Cal/cm. sec |

46.5 |

200 |

Acid Resistance |

/ |

5times higher than the usual TC |

Resist chemical media |

Carbon Graphite

- Features :

-

Self-lubricating properties reduce friction.

Good thermal and electrical conductivity.

Chemically inert in non-oxidizing environments. - Applications :

-

Dry-running or low-lubrication conditions.

Food processing, pharmaceuticals, and water systems.

-

Temperature Range: -200°C to 400°C (in inert atmospheres).

Type |

Brand |

Density (g/cm3) |

Fractural Strength (MPa) |

Compressive Strength (MPa) |

Hardness |

Porosity |

Temperatures (℃) |

M106H |

Impregnated Epoxy Resin(B1) |

1.75 |

65 |

200 |

85 |

<1 |

250 |

M120H |

1.7 |

60 |

180 |

80 |

<1 |

250 |

|

M106K |

Impregnated Furan Resin(B) |

1.75 |

67 |

200 |

90 |

<1 |

250 |

M120H |

1.7 |

62 |

180 |

85 |

<1 |

250 |

|

M106F |

Impregnated Phenol Aldehyde Resin(B2) |

1.75 |

60 |

200 |

85 |

250 |

|

M120F |

1.7 |

55 |

180 |

80 |

<1 |

250 |

|

M106D |

Antimony Carbon (A) |

2.3 |

65 |

220 |

90 |

<1.5 |

400 |

M120D |

2.3 |

60 |

220 |

90 |

<1.5 |

400 |

|

M254D |

2.3 |

55 |

210 |

65 |

<1.5 |

450 |

Ceramic

- Features :

-

High temperature resistance.

Corrosion resistance and wear resistance.

Good sealing performance. - Applications :

-

It is widely used in aerospace technology, machinery, metallurgy, printing and dyeing, food, pharmaceutical, automobile industry, etc.

-

Temperature Range: Up to 1000°C or higher.

Technical Parameter |

Unit |

95% |

99% |

99.50% |

Content of Al203 |

% |

≧95 |

≦99 |

≦99 |

Density |

g/cm3 |

3.7 |

3.88 |

3.9 |

Hardness |

HRA |

85 |

88 |

90 |

Porosity Rate |

% |

<0.4 |

<0.2 |

<0.15 |

Fractural Strength |

MPa |

250 |

310 |

350 |

Coefficient of Heat Expansion |

10-6/K |

5.5 |

5.3 |

5.2 |

Thermal Conductivity |

W/mK |

27.8 |

26.7 |

26 |

Variety |

Main Feature and Suitable Scope |

FPM |

Resistant against: Heat, oil, reagents. High temperature but sensitive to mechanical damage. Suitable for most acids and alkalis, except strong alkalis. Application temperature: -30℃~210℃ |

EPDM |

Resistant against: Chemical reagents. Suitable for hydraulic oil of organic phosphate. Application temperature: -50℃~150℃ |

NBR |

Resistant against: Oil, high pressure, wear. High elasticity and mechanical strength. Suitable for general hydraulic and pneumatic seal; Unsuitable for working under sunlight and ultraviolet; Restricted ability to withstand strong acids. Application temperature: -20℃~120℃ |

SILICON RUBBER |

Resistant against: Heat, freeze, low mechanical strength, poor bending and not wear. Suitable for fixed seal resistant to heat and freeze. Unsuitable for working under high mechanical strength. Application temperature: -80℃~200℃ |

CR |

Resistant against: Oil, wear, good bending. Especially suitable for pneumatic machinery and hydraulic fluid at high aniline content. Application temperature: -40℃~120℃ |

HNBR |

Resistant against: Gasoline, freon, oil, acid, alkali, heat and freeze. High mechanical strength and wear. |

FFKM:

It is widely used in semiconductor manufacture, petrochemical, gas extraction, medical, food and aerospace industries.

Dupont-Kalrez | |||

Property |

Unit |

Kalrez 6375 |

Kalrez 4079 |

Tensile Strength @ Break |

MPa |

15.1 |

16.9 |

kgf/cm |

/ |

154 |

172 |

Modulous @100% |

MPa |

7.2 |

7.3 |

kgf/cm2 |

/ |

73.4 |

74 |

Elongation percentage @Break |

% |

160 |

150 |

Hardness |

HS |

75 |

75 |

Heat Resistance Temperature |

℃ |

275 |

316 |

70 hr in room temperature |

/ |

/ |

22 |

70 hr at 204℃ |

/ |

30 |

25 |

China -FFKM | ||

Property |

unit |

|

Hardness |

HS |

72 |

Tensile Strength @ Break |

MPa |

20 |

Elongation Percentage @ Break |

% |

175 |

Modulous @100% |

MPa |

10.5 |

Heat Resistance Temperature |

℃ |

270℃ |

70 hr in room temperature |

/ |

19 |

70 hr at 204 ℃ |

/ |

49 |

-

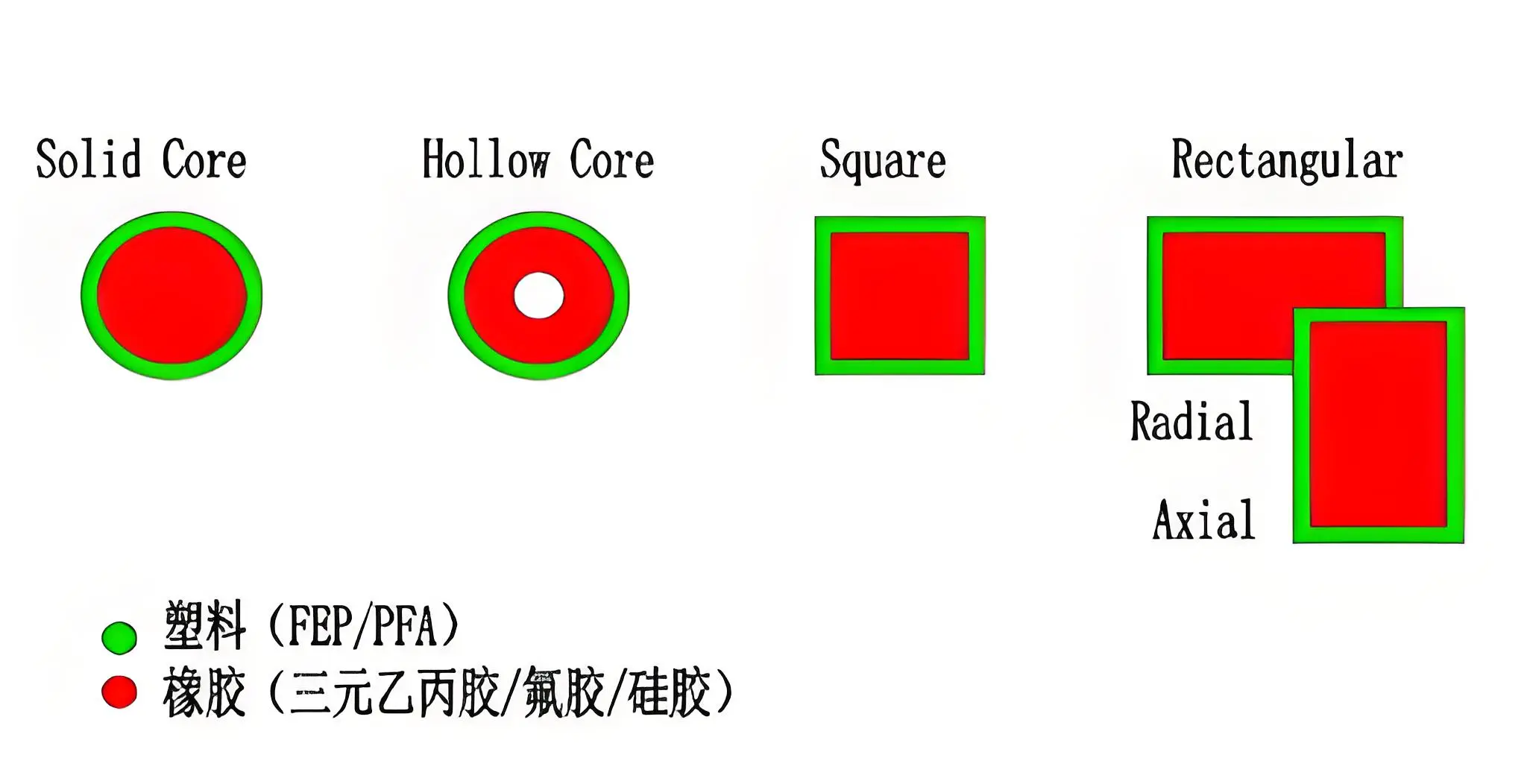

Polytetrafluoroethylene (PTFE)

- Features :

-

Outstanding chemical resistance to aggressive media.

Low friction and anti-stick properties.

Flexible but prone to cold flow under pressure. - Applications :

-

Highly corrosive environments (e.g., sulfuric acid, chlorine).

Food-grade or hygienic applications.

-

Temperature Range: -200°C to 260°C.

-

Stainless Steel (SS 316, SS 304)

- Features :

-

Good mechanical strength and corrosion resistance.

Cost-effective for moderate conditions.

Vulnerable to chlorides and extreme acids. - Applications :

-

General-purpose seals in water, oils, and mild chemicals.

HVAC systems and marine equipment.

-

Temperature Range:-50°C to 400°C.

Operating Condition |

Recommended Material |

High abrasion (slurries, solids) |

Silicon Carbide, Tungsten Carbide |

Strong acids/alkalis |

PTFE, Silicon Carbide |

High temperature (>300°C) |

Silicon Carbide, Special Alloys |

Food/pharmaceutical contact |

PTFE, EPDM, Carbon Graphite |

Low-cost, general-purpose |

Stainless Steel, NBR |

Temperature & Pressure: Material performance degrades beyond rated limits.

Cost vs. Lifespan: Harder materials (e.g., SiC) have higher upfront costs but longer service life.

Pairing: Combine materials (e.g., SiC vs. Carbon) to optimize wear resistance.