M74-D Double End Multi-Spring Mechanical Seal for Plain Shafts

Scopes of Application:

This robust seal is engineered for critical sealing applications in various equipment, including:

• Chemical Centrifugal Pumps: Reliable sealing for process fluids and mild corrosives.

• Wastewater & Water Pump Seals: Effective performance in clean water, sewage, and treatment systems. (e.g., KSB/Kaiquan Water Pumps)

• Pulp & Paper Pump Seals: Handles low-abrasive media in stock and circulation pumps.

• Marine Lube Oil Seals: Trusted sealing for onboard pump systems in shipbuilding.

• General Industrial Double Suction Pump Seals: A versatile solution for multiple rotating equipment sealing oil, water, and other low solids content media.

Product Detail

The seal adheres to the EN 12756 standard, ensuring dimensional compatibility and interchangeability. It is specifically compatible with popular chemical process pumps like the Goulds IC i-FRAME series (e.g., models IC 100-65-160, IC 100-65-200, IC 100-65-250).

Equivalent Products

• AESseal®: M010D

Our GW M74A is a high-quality, ISO9001-certified alternative that matches the performance and specifications of leading international brands, offering a cost-effective solution without compromising on reliability.

Material and Operating Range

Construction Materials:

• Rotary Ring: Carbon / Silicon Carbide (SiC) / Tungsten Carbide (TC)

• Stationary Ring: 99% Ceramic / Silicon Carbide (SiC) / Tungsten Carbide (TC)

• O-Ring: VITON / NBR / EPDM

• Spring & Metallic Parts: SUS304 / SUS316

* Custom configurations are available to meet specific operational needs. Please contact us to discuss your requirements for material and parameter adjustments.

Operating Range:

• Temperature: -40 ℃~220℃

• Pressure: ≤2 MPa

• Speed: 20 m/s

• Performance: Moderately corrosive

Mediums:

• Oil

• Water

• Sewage water

• Pulp and paper

• Other low solid content media/ low abrasive media

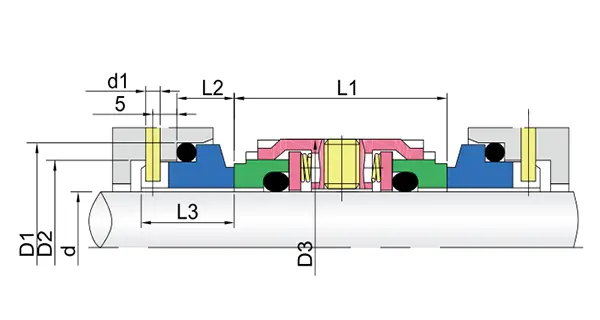

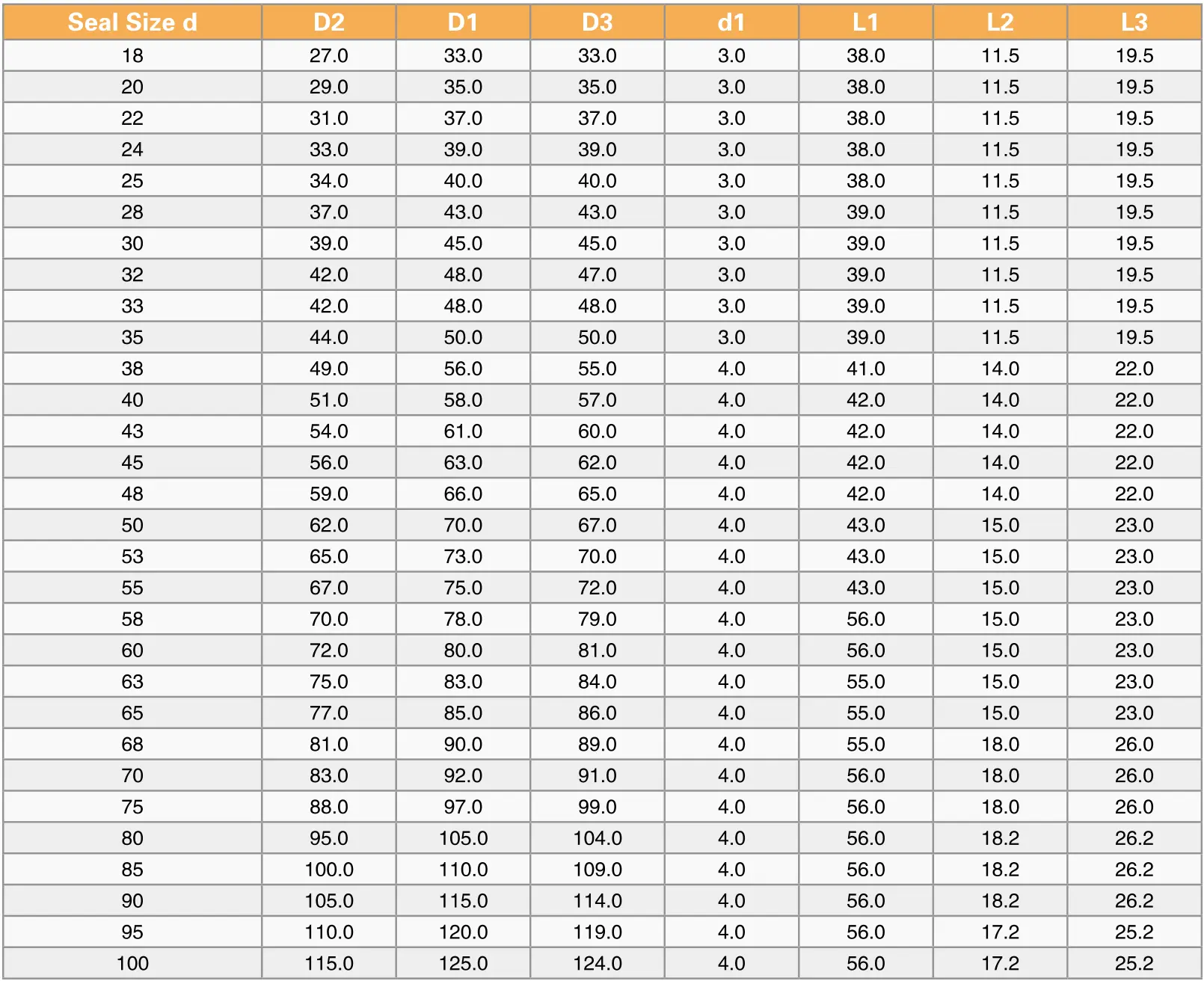

• Installation Dimensions

Installation Dimensions

description2