01

01

01

01

Important Precautions

GW seal has been committed to bringing satisfactory products and services to

customers from all walks of life.

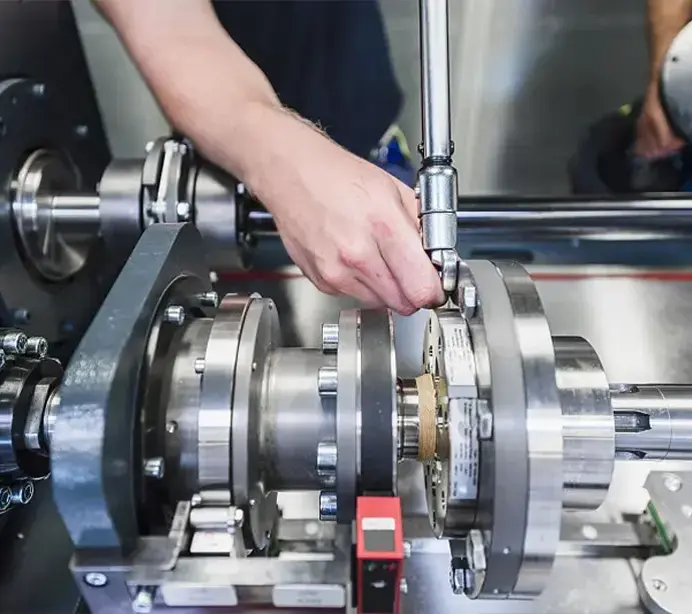

Avoid Seal Face Damage: Never touch the polished seal faces with bare hands or tools.

Correct Lubrication: Use only recommended lubricants to prevent O-ring swelling or degradation.

Handle with Care: Do not drop the seal or expose it to impact.

Temperature Sensitivity: Store seals away from direct sunlight or extreme temperatures before installation.

Material Compatibility: Confirm seal materials (e.g., elastomers, ceramics) are suitable for the fluid being sealed.

No matter what your sealing challenges are, we are here to deliver the most reliable and advanced mechanical sealing solutions. Trust us, you will receive not only high-quality sealing products, but also thoughtful technical support and expert services from start to finish. Let’s work together to build a more efficient, sustainable, and innovative future!

Regular Inspections

Get valuable maintenance advice for reliable mechanical seals.

- Check for leaks, vibration, or temperature changes during operation.

- Inspect seal faces for wear or scoring during scheduled downtime.

- Inspect seal faces for wear or scoring during scheduled downtime.

Lubrication

Get valuable maintenance advice for reliable mechanical seals.

- Reapply compatible lubricant to O-rings during maintenance (if removable).

Cleanliness

Get valuable maintenance advice for reliable mechanical seals.

- Flush the system to remove abrasive particles if handling dirty fluids.

Replacement

Get valuable maintenance advice for reliable mechanical seals.

- Replace the seal immediately if leakage exceeds acceptable limits or faces show significant wear.

Storage

Get valuable maintenance advice for reliable mechanical seals.

- Keep spare seals in original packaging, away from UV light, ozone, or moisture.

REQUEST A QUOTE

Need a Consultation? Contact Us 24/7