Imperial Size Mechanical Shaft Seals Replacement for John Crane 8B1

This multi-spring mechanical seal component is engineered for medium and heavy-purpose applications with imperial shaft sizes. It is available in a wide variety of materials for handling practically every industrial fluid.

Industrial Applications:

Engineered for medium to heavy-duty services in critical industries:

• Refinery process pumps (crude & refined products)

• Chemical processing equipment (acids/alkalis)

• Petrochemical rotating machinery

• Oil & gas transfer systems

• High-speed mixers and agitators (≤25m/s)

• Other rotating equipment

Product Detail:

• Multi-spring mechanism: Even circumferential loading for improved pV capability

• Hex-key set screw drive: Positive shaft engagement in bidirectional operation

• Dual cross-section design: Full/narrow profiles for space-constrained applications

• O ring centered sealing: Reliable leak-free performance under ≤5MPa pressure

Technical Superiority:

• 25% higher pV values versus single-spring seals (FSA Test 2107)

• -40℃~250℃ thermal stability for extreme process conditions

• Interchangeable imperial sizing for direct OEM replacement

Validated Equipment Compatibility:

• Howden WRV204 Mk5E compressors

• API 682 compliant pump models

Equivalent Products

• JohnCrane®: Type 8B1

• Vulcan®: Type 1609BS

• Flexaseal®: Type 8B-1

• Flowserve®: M412LZ028

* ISO9001-certified alternatives with identical dimensions and 40% cost efficiency.

* Additionally, we provide other models within this product line, including the 8BT, 8-1, and 8-1T.

Material and Operating Range

Material:

• Rotary ring: Carbon/Silicon Carbide (SiC)/Tungsten Carbide (TC)

• Stationary ring: 99%Ceramic/SiC/TC

• Sealing elements: VITON/NBR/EPDM

• Metallic components: SUS304/SUS316

* Customization: Supported. Please contact us for changing parameters and materials.

Operating Range:

• Temperature: -40 ℃~250℃

• Pressure: ≤5MPa

• Speed: 25m/s

• Performance: Moderate corrosion resistance

Media compatibility:

• Crude & refined hydrocarbons

• Process water & cooling fluids

• Inorganic acids/alkalis (pH 2-12)

• Aromatic solvents and amines

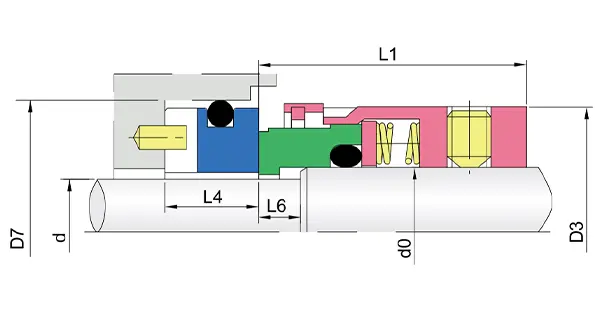

Installation Dimensions

| Seal Size d0 (inches) | d | d0 | D3 | D7 | L1 | L4 | L6 |

| 1.000 | 22.20 | 25.40 | 39.67 | 38.10 | 33.32 | 11.10 | 8.00 |

| 1.125 | 25.40 | 28.58 | 42.85 | 41.28 | 34.93 | 11.10 | 7.90 |

| 1.250 | 28.50 | 31.75 | 47.63 | 44.44 | 34.93 | 11.10 | 7.90 |

| 1.375 | 28.50 | 34.93 | 50.80 | 44.44 | 36.50 | 11.10 | 8.70 |

| 1.500 | 31.70 | 38.10 | 53.98 | 47.63 | 36.50 | 11.10 | 8.70 |

| 1.625 | 34.90 | 41.28 | 60.33 | 50.80 | 44.45 | 12.70 | 8.70 |

| 1.750 | 38.10 | 44.45 | 63.50 | 53.98 | 44.45 | 12.70 | 9.50 |

| 1.875 | 41.20 | 47.63 | 66.68 | 60.33 | 44.45 | 12.70 | 9.50 |

| 2.000 | 44.40 | 50.80 | 69.85 | 63.50 | 44.45 | 12.70 | 9.50 |

| 2.125 | 47.60 | 53.98 | 76.20 | 66.68 | 52.37 | 14.27 | 11.10 |

| 2.250 | 50.80 | 57.15 | 79.38 | 69.85 | 52.37 | 14.27 | 11.10 |

| 2.375 | 53.90 | 60.33 | 82.55 | 76.20 | 52.37 | 14.27 | 11.10 |

| 2.500 | 57.10 | 63.50 | 85.73 | 79.30 | 52.37 | 14.27 | 11.10 |

| 2.625 | 60.30 | 66.68 | 88.90 | 82.55 | 52.37 | 15.88 | 11.10 |

| 2.750 | 63.50 | 69.85 | 92.08 | 85.73 | 52.37 | 15.88 | 11.10 |

| 2.875 | 66.60 | 73.03 | 95.25 | 85.73 | 52.37 | 15.88 | 11.10 |

| 3.000 | 69.80 | 76.20 | 96.82 | 88.90 | 52.37 | 15.88 | 11.10 |

| 3.125 | 73.00 | 79.38 | 100.00 | 95.25 | 52.37 | 19.84 | 11.10 |

| 3.250 | 76.20 | 82.55 | 104.78 | 98.43 | 52.37 | 19.84 | 14.30 |

| 3.375 | 79.30 | 85.73 | 107.95 | 101.60 | 52.37 | 19.84 | 14.30 |

| 3.500 | 82.50 | 88.90 | 111.13 | 104.78 | 52.37 | 19.84 | 14.30 |

| 3.625 | 85.70 | 92.08 | 114.30 | 107.95 | 52.37 | 19.84 | 14.30 |

| 3.750 | 88.90 | 95.25 | 117.48 | 111.13 | 52.37 | 19.84 | 14.30 |

| 3.875 | 92.00 | 98.43 | 120.65 | 114.30 | 52.37 | 19.84 | 14.30 |

| 4.000 | 95.20 | 101.60 | 123.83 | 117.48 | 52.37 | 19.84 | 14.30 |

description2