01

High Temperature Metal Bellows Mechanical seals MFL85N

This high temperature mechanical seal is engineered for demanding applications involving extreme temperature variations and highly viscous media. It is ideally suited for:

• Chemical process industry applications• Oil and gas processing equipment

• Refining technology operations

• High viscosity pump seals in various industries

Product Detail

+

The GW 685 metal bellows seal represents advanced sealing technology that effectively addresses chemical corrosion issues associated with elastomer seals. The metal bellows design provides positive shaft drive transmission while eliminating the need for dynamic elastomers. This balanced type seal features a compact design with shorter installation length compared to conventional seals, ensuring reliable performance and extended service life.

The bellows assembly ensures constant face loading while compensating for shaft misalignment, thermal expansion, and wear. The innovative design protects the shaft and sleeve from wear and scoring, with the drive mechanism eliminating excessive stress on the bellows components.

Its stationary seal face complies with EN12756 (DIN 24960) dimensional standards.

The bellows assembly ensures constant face loading while compensating for shaft misalignment, thermal expansion, and wear. The innovative design protects the shaft and sleeve from wear and scoring, with the drive mechanism eliminating excessive stress on the bellows components.

Its stationary seal face complies with EN12756 (DIN 24960) dimensional standards.

Equivalent Products

+

• EagleBurgmann®: Type MFL85N

We provide related product such as Burgmann MFLWT80 as well, please contact us for more information.

*Our ISO9001 certified product can work as an alternative to the brands above with identical dimensional specifications and performance characteristics.

We provide related product such as Burgmann MFLWT80 as well, please contact us for more information.

*Our ISO9001 certified product can work as an alternative to the brands above with identical dimensional specifications and performance characteristics.

Material and Operating Range

+

Construction Material:

• Rotary ring: Carbon/SiC/TC

• Stationary ring: 99% Ceramic /SiC/TC

• Metal bellow: AM350

• O-ring: VITON/EPDM/Encapsulated Ring

• Metallic Parts: SUS304/SUS316

* Custom configurations available for special requirements, please contact us!

Operating Range:

• Temperature: -40 ℃~220℃

• Pressure: ≤2.1 MPa

• Speed: ≤20 m/s

Mediums:

• Oil and gas products

• Water and wastewater

• Chemical contents and corrosive fluids

• High viscosity media

• Process fluids in refining applications

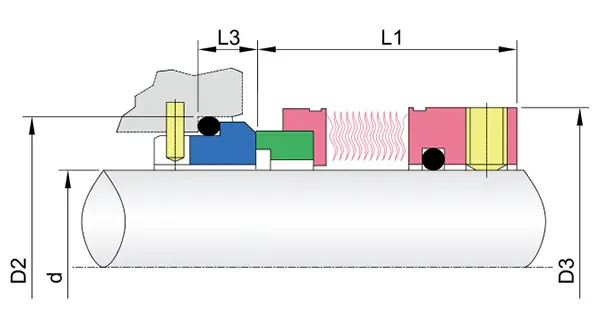

Installation Dimensions

+

| Seal Size | D3 | D2 | L1 | L3 |

| 16 | 30.0 | 27.0 | 32.5 | 10.0 |

| 18 | 32.0 | 33.0 | 30.5 | 11.5 |

| 20 | 33.5 | 35.0 | 30.5 | 11.5 |

| 22 | 36.5 | 37.0 | 30.5 | 11.5 |

| 24 | 39.0 | 39.0 | 28.5 | 11.5 |

| 25 | 39.6 | 40.0 | 28.5 | 11.5 |

| 28 | 42.8 | 43.0 | 31.0 | 11.5 |

| 30 | 45.0 | 45.0 | 31.0 | 11.5 |

| 32 | 46.0 | 48.0 | 31.0 | 11.5 |

| 33 | 48.0 | 48.0 | 31.0 | 11.5 |

| 35 | 49.2 | 50.0 | 31.0 | 11.5 |

| 38 | 52.3 | 56.0 | 31.0 | 14.0 |

| 40 | 55.5 | 58.0 | 31.0 | 14.0 |

| 43 | 57.5 | 61.0 | 31.0 | 14.0 |

| 45 | 58.7 | 63.0 | 31.0 | 14.0 |

| 48 | 61.9 | 66.0 | 31.0 | 14.0 |

| 50 | 65.0 | 70.0 | 32.5 | 15.0 |

| 53 | 68.2 | 73.0 | 32.5 | 15.0 |

| 55 | 70.0 | 75.0 | 32.5 | 15.0 |

| 58 | 71.7 | 78.0 | 37.5 | 15.0 |

| 60 | 74.6 | 80.0 | 37.5 | 15.0 |

| 63 | 79.0 | 83.0 | 37.5 | 15.0 |

| 65 | 84.1 | 85.0 | 37.5 | 15.0 |

| 68 | 87.3 | 90.0 | 34.5 | 18.0 |

| 70 | 87.3 | 92.0 | 42.0 | 18.0 |

| 75 | 95.0 | 97.0 | 42.0 | 18.0 |

| 80 | 98.4 | 105.0 | 41.8 | 18.2 |

| 85 | 104.7 | 110.0 | 41.8 | 18.2 |

| 90 | 111.0 | 115.0 | 46.8 | 18.2 |

| 95 | 114.0 | 120.0 | 47.8 | 17.2 |

| 100 | 117.4 | 125.0 | 47.8 | 17.2 |

description2