01

GWT93 22MM OEM Parallel Spring Seal for Alfa Laval Pumps LKH

Overview

The GW T93-22 is a high-performance OEM mechanical seal engineered for Alfa Laval centrifugal and rotary lobe pumps. It ensures reliable operation in hygienic and industrial fluid handling applications, providing a direct replacement for original equipment seals with identical dimensional fit and performance.

Product Detail

+

The GW T93-22 seal features a durable parallel spring mechanism that maintains consistent pressure on sealing faces, reducing wear in dynamic applications. This design provides superior stability compared to single-spring seals, particularly in high-speed and high-vibration environments. The combination of carbon/silicon carbide rotary rings and SUS304/SUS316/TC stationary rings ensures extended service life under thermal cycling and mechanical stress. These material pairings offer excellent resistance to abrasion and chemical attack, maintaining seal integrity across a wide range of demanding media. Its design simplifies installation, eliminating complex adjustments and ensuring immediate operational readiness by preserving critical face flatness and perpendicularity during assembly.

Typical Applications

• Food, dairy, and beverage processing (e.g., pasteurizers, homogenizers)

• Pharmaceutical and biotech fluid transfer systems

• Cosmetic and chemical manufacturing

• CIP/SIP-compatible equipment

Typical Applications

• Food, dairy, and beverage processing (e.g., pasteurizers, homogenizers)

• Pharmaceutical and biotech fluid transfer systems

• Cosmetic and chemical manufacturing

• CIP/SIP-compatible equipment

Cross-Reference & Compatibility

+

• Compatible Pumps: Alfa Laval LKH and SRU series

• Equivalent Models:

o AESseal®: P07U (parallel spring seal)

o Roplan®: RTH81/82/84

• Equivalent Models:

o AESseal®: P07U (parallel spring seal)

o Roplan®: RTH81/82/84

Material and Operating Range

+

Materials & Specifications:

• Rotary Seal Face: Carbon/Silicon Carbide

• Stationary Seal Face: SUS304/SUS316/SiC/TC (Tungsten Carbide)

• Secondary Seals: VITON®/EPDM

• Metallic Parts: SUS304/SUS316 stainless steel

*Custom material configurations available for specific media or temperatures.

Operating Parameters:

• Temperature: -20°C to +150°C (up to 180°C with specialized elastomers)

• Pressure: ≤ 1.5 MPa (15 bar)

• Rotational Speed: ≤ 3000 RPM

• Applicable Media: Water, steam, dairy products, solvents, mild acids, and alkalis

• Rotary Seal Face: Carbon/Silicon Carbide

• Stationary Seal Face: SUS304/SUS316/SiC/TC (Tungsten Carbide)

• Secondary Seals: VITON®/EPDM

• Metallic Parts: SUS304/SUS316 stainless steel

*Custom material configurations available for specific media or temperatures.

Operating Parameters:

• Temperature: -20°C to +150°C (up to 180°C with specialized elastomers)

• Pressure: ≤ 1.5 MPa (15 bar)

• Rotational Speed: ≤ 3000 RPM

• Applicable Media: Water, steam, dairy products, solvents, mild acids, and alkalis

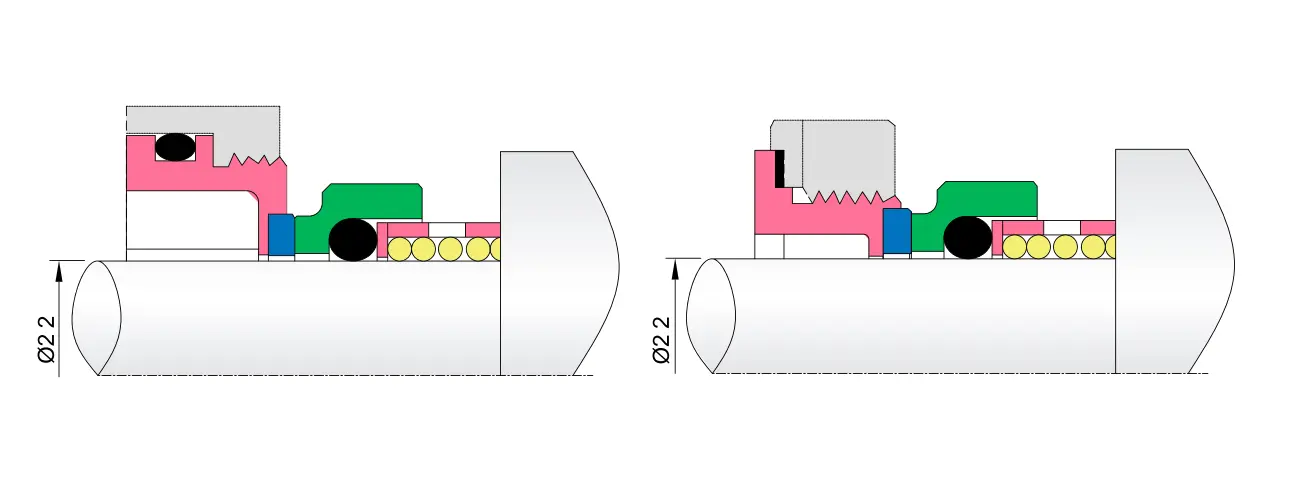

Installation Dimensions

+

• Standard Shaft Sizes: 22mm (Please quote for other sizes)

• Standard Shaft Sizes: 22mm (Please quote for other sizes)• Dimensional drawings and installation guidelines provided with order

• Custom solutions available for non-standard pump configurations

description2