GWL9 Cartridge Seal for Food and Beverage Industry Replace AES CS

The GW L9 is a versatile externally mounted cartridge mechanical seal designed as a direct replacement for the AES seal CS series. Its balanced face and non‑metallic fluid‑contact materials ensure reliable performance in a range of industrial environments, while the pre‑set dimensions allow for quick, error‑free installation.

Product Detail

Equivalent Products

Material and Operating Range

Materials:

*Custom material selections and special dimensions can be provided to meet specific application requirements.

Operating Range:

- Speed: ≤ 15 m/s

Compatible Media:

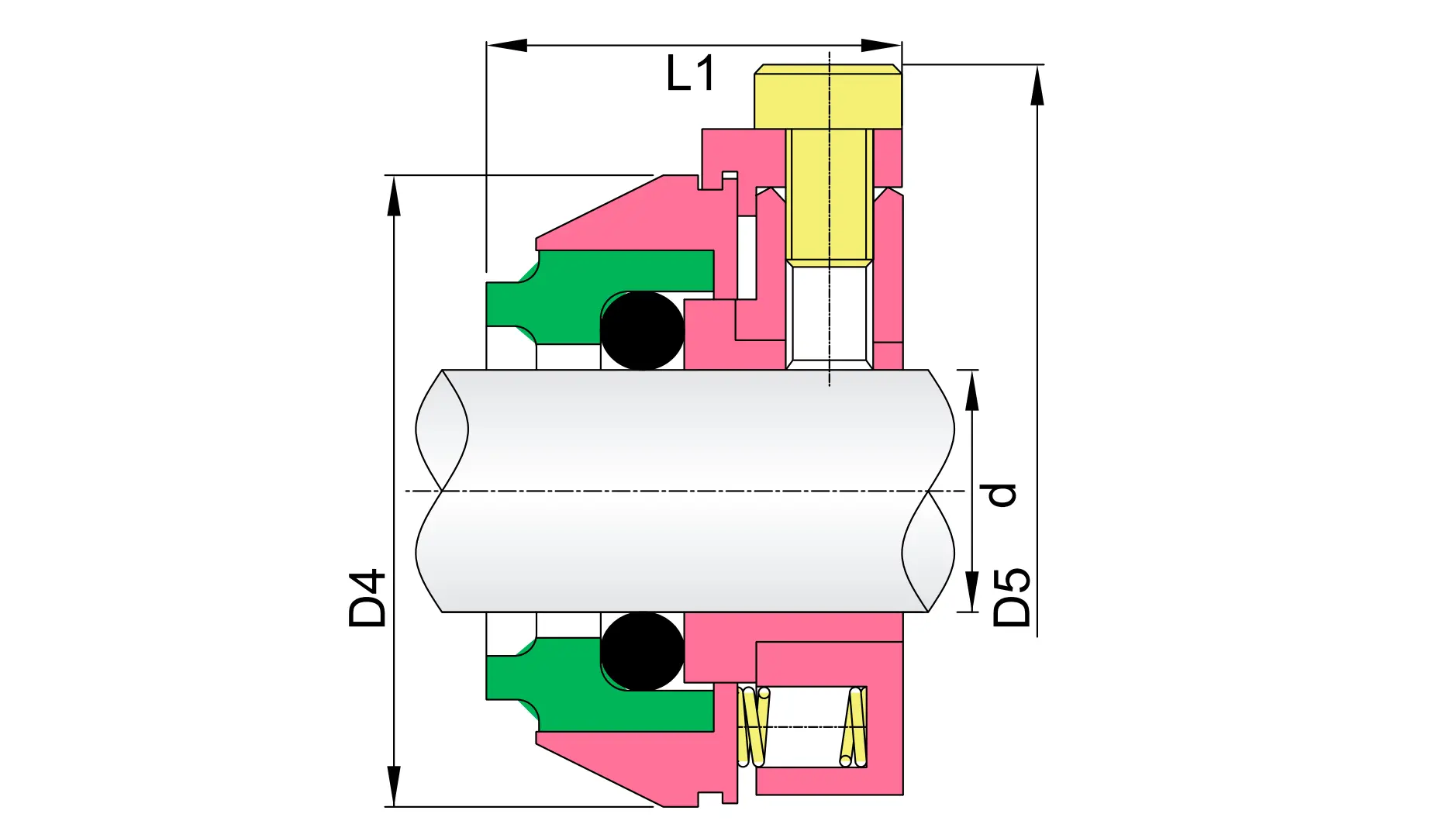

Installation Dimensions

Available in both metric and inch shaft sizes to match AES CS seal interchangeability. Common sizes include:

Size |

L1 |

D4 |

D5 |

|

Size |

L1 |

D4 |

D5 |

20 |

27.91 |

45.30 |

59.80 |

|

0.625" |

1.098 |

1.622 |

2.192 |

22 |

27.91 |

47.30 |

61.80 |

|

0.750" |

1.098 |

1.747 |

2.317 |

24 |

27.90 |

49.30 |

63.80 |

|

0.875" |

1.098 |

1.872 |

2.442 |

25 |

27.90 |

50.30 |

64.80 |

|

1.000" |

1.098 |

1.997 |

2.567 |

28 |

27.91 |

53.30 |

67.80 |

|

1.125" |

1.098 |

2.122 |

2.692 |

30 |

27.91 |

55.30 |

69.80 |

|

1.250" |

1.098 |

2.247 |

2.817 |

32 |

27.91 |

57.30 |

71.80 |

|

1.375" |

1.098 |

2.372 |

2.942 |

33 |

27.90 |

58.30 |

72.80 |

|

1.500" |

1.098 |

2.497 |

2.067 |

35 |

27.91 |

60.30 |

74.80 |

|

1.625" |

1.098 |

2.622 |

3.192 |

38 |

27.91 |

63.30 |

77.80 |

|

1.750" |

1.098 |

2.747 |

3.317 |

40 |

27.91 |

65.30 |

79.80 |

|

1.875" |

1.098 |

2.872 |

3.442 |

42 |

27.90 |

67.30 |

81.80 |

|

2.000" |

1.098 |

2.997 |

3.567 |

43 |

27.90 |

68.30 |

82.80 |

|

2.125" |

1.098 |

3.122 |

3.692 |

45 |

27.91 |

70.30 |

84.80 |

|

2.250" |

1.098 |

3.247 |

3.817 |

48 |

27.91 |

73.30 |

87.80 |

|

2.375" |

1.098 |

3.372 |

3.942 |

50 |

27.90 |

75.30 |

89.80 |

|

2.500" |

1.098 |

3.497 |

4.067 |

53 |

27.91 |

78.30 |

92.80 |

|

2.625" |

1.192 |

3.866 |

4.436 |

55 |

27.90 |

80.30 |

94.80 |

|

2.750" |

1.192 |

3.991 |

4.561 |

60 |

27.91 |

85.30 |

99.70 |

|

2.875" |

1.192 |

4.116 |

4.686 |

65 |

30.30 |

96.50 |

111.00 |

|

3.000" |

1.192 |

4.241 |

4.811 |

70 |

30.28 |

101.50 |

116.00 |

|

3.125" |

1.192 |

4.366 |

4.936 |

75 |

30.28 |

106.50 |

121.00 |

|

3.250" |

1.192 |

4.491 |

5.061 |

80 |

30.28 |

111.50 |

126.00 |

|

3.375" |

1.192 |

4.616 |

5.186 |

85 |

30.28 |

116.50 |

131.00 |

|

3.500" |

1.192 |

4.741 |

5.311 |

90 |

30.28 |

121.50 |

136.00 |

|

3.625" |

1.192 |

4.866 |

5.436 |

95 |

30.30 |

126.50 |

141.00 |

|

2.750" |

1.192 |

4.991 |

5.561 |

100 |

30.28 |

131.50 |

146.00 |

|

2.875" |

1.192 |

5.116 |

5.686 |

|

|

|

|

|

4.000" |

1.192 |

5.241 |

5.811 |

*Full dimensional drawings are available upon request. Please contact our technical team for specific size confirmation and CAD files.

description2