01

GW260 For APV PUMA Centrifugal Pump

This mechanical seal is designed to deliver reliable performance in a wide range of processing applications. It is particularly well-suited for:

• Food, dairy, and beverage processing systems

• Pharmaceutical and cosmetic manufacturing

• CIP (Clean-in-Place) and SIP (Steam-in-Place) applications

• Chemical and solvent transfer operations

Product Description

+

The GW 260 is a high-performance OEM mechanical seal specifically engineered for APV Puma series pumps. This seal features a proven single spring design that provides sufficient and consistent closing force, making it particularly adept at handling viscous fluids or media with mild abrasives. The precision-engineered sealing faces—carbon versus silicon carbide or ceramic—ensure extended service life in demanding applications involving thermal cycling and frequent cleaning cycles.

As a direct replacement for original equipment seals, the GW 260 provides identical dimensional fit and performance characteristics. The cartridge construction eliminates complex installation procedures, ensuring proper seal function from initial startup.

As a direct replacement for original equipment seals, the GW 260 provides identical dimensional fit and performance characteristics. The cartridge construction eliminates complex installation procedures, ensuring proper seal function from initial startup.

Compatibility & Equivalents

+

Compatible Pumps: APV Puma series pumps (1.0” and 1.5” shaft sizes)

Equivalent Models:

• AESseal®: P06U

• John Crane®: R0SR

• Vulcan®: Type 26

• Flowserve® (PAC seal): Type APU

• Roten®: 37

• Roplan®: R50

• AESseal®: P06U

• John Crane®: R0SR

• Vulcan®: Type 26

• Flowserve® (PAC seal): Type APU

• Roten®: 37

• Roplan®: R50

Material and Operating Range

+

Materials of Construction:

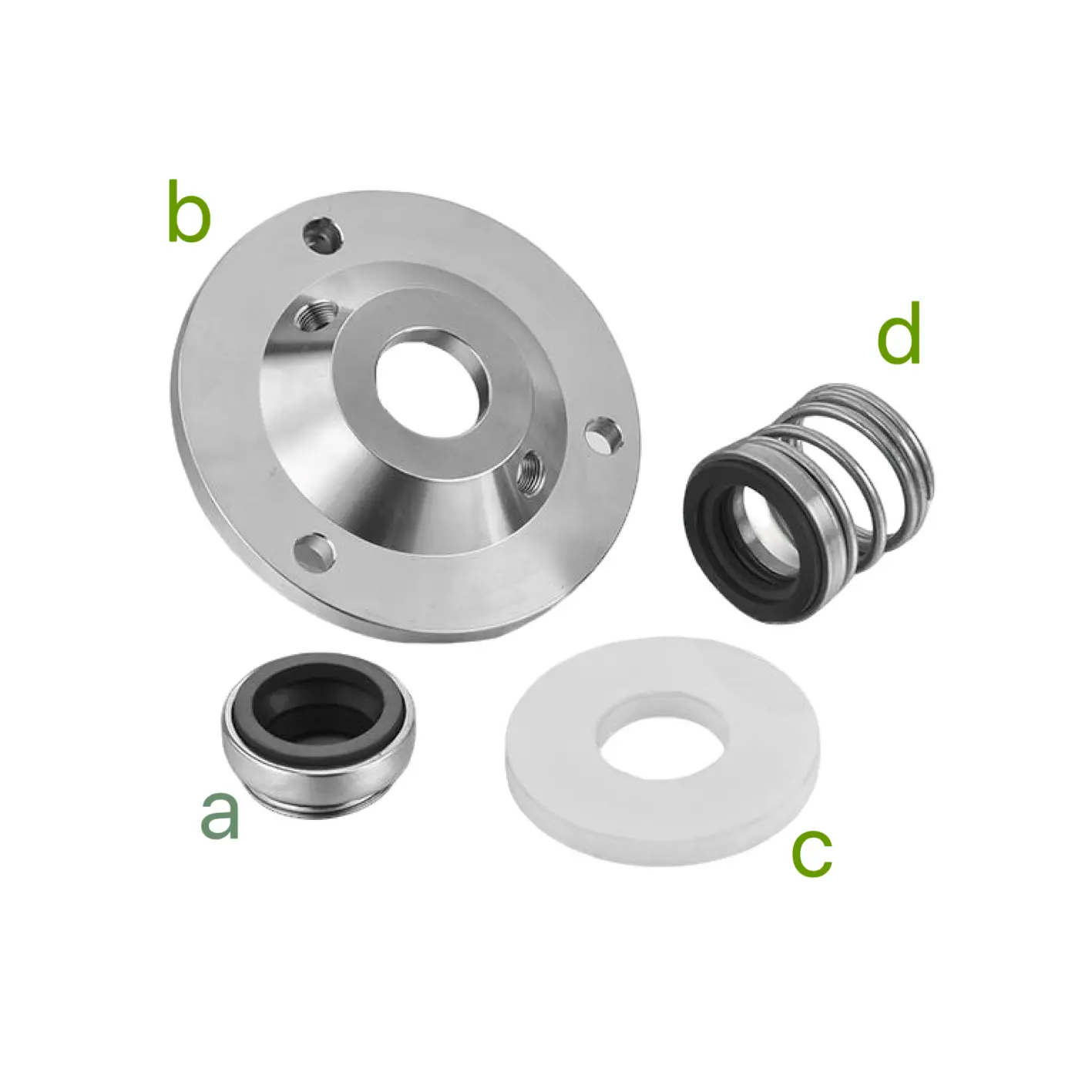

• a.d. Rotary ring: Carbon

• b.c. Stationary ring: SUS304/SUS316/SiC/Ceramic

• Secondary seal: VITON/NBR/EPDM

• Spring and Metal Parts: SUS304/SUS316

* Custom material combinations and special configurations available for specific application requirements.

Operating Range:

• Temperature: -20°C to +150°C (up to 180°C with specialized elastomers)

• Pressure: ≤ 1.5 MPa (15 bar)

• Rotational Speed: ≤ 3000 RPM

• Applicable Media: Water, steam, dairy products, beverages, pharmaceuticals, mild chemicals, and industrial process fluids

• a.d. Rotary ring: Carbon

• b.c. Stationary ring: SUS304/SUS316/SiC/Ceramic

• Secondary seal: VITON/NBR/EPDM

• Spring and Metal Parts: SUS304/SUS316

* Custom material combinations and special configurations available for specific application requirements.

Operating Range:

• Temperature: -20°C to +150°C (up to 180°C with specialized elastomers)

• Pressure: ≤ 1.5 MPa (15 bar)

• Rotational Speed: ≤ 3000 RPM

• Applicable Media: Water, steam, dairy products, beverages, pharmaceuticals, mild chemicals, and industrial process fluids

Installation Dimensions

+

• Standard shaft sizes: 1.0” and 1.5”

Complete dimensional drawings and installation guidelines available upon request. For pumps with non-standard shaft dimensions, contact our technical support team for customized solutions.

Complete dimensional drawings and installation guidelines available upon request. For pumps with non-standard shaft dimensions, contact our technical support team for customized solutions.

description2