01

GW T50 for Inoxpa Prolac Centrifugal Pumps

This mechanical seal delivers reliable performance in demanding sanitary processing applications. It is particularly well-suited for:

• Dairy, food, and beverage processing

• Pharmaceutical and cosmetic manufacturing

• Chemical transfer applications

• CIP and SIP systems

• High-purity water systems

Product Description

+

The GW T50 is a high-performance OEM mechanical seal specifically engineered for INOXPA® PROLAC series centrifugal pumps. This seal features precision-engineered sealing faces with advanced material combinations including Silicon Carbide (SiC) and Tungsten Carbide (TC), ensuring exceptional wear resistance in continuous operation. The optimized face geometry and spring loading system provide consistent sealing performance even under shaft deflection and vibration conditions.

The pre-assembled design eliminates complex installation procedures, reducing maintenance downtime and ensuring optimal performance from initial startup. This seal is particularly effective in applications requiring frequent sterilization and resistance to cleaning agents, providing reliable sealing performance in challenging processing environments. The seal's robust construction withstands thermal cycling and mechanical stress, making it ideal for continuous operation in 24/7 production facilities.

The pre-assembled design eliminates complex installation procedures, reducing maintenance downtime and ensuring optimal performance from initial startup. This seal is particularly effective in applications requiring frequent sterilization and resistance to cleaning agents, providing reliable sealing performance in challenging processing environments. The seal's robust construction withstands thermal cycling and mechanical stress, making it ideal for continuous operation in 24/7 production facilities.

Compatibility & Equivalents

+

• Target Pumps: INOXPA® PROLAC series centrifugal pumps

• Equivalent Models: AESseal®: M07U, Roplan®: 52, Rotan®: S, Vulcan®: 50

• Equivalent Models: AESseal®: M07U, Roplan®: 52, Rotan®: S, Vulcan®: 50

Material and Operating Range

+

Materials:

• Rotary Ring: Carbon, Silicon Carbide (SiC), or Tungsten Carbide (TC)

• Stationary Ring: SiC, SUS304, SUS316, or TC

• Secondary Seals: VITON®, EPDM, or NBR

• Metallic Components: SUS304/SUS316 stainless steel

* Custom material configurations are available for specific application requirements.

Operating Range:

• Temperature: -10°C to +120°C (up to 140°C for short-term SIP)

• Pressure: ≤ 1.6 MPa (16 bar)

• Speed: ≤ 3600 rpm

• Applicable Media: Water, steam, dairy products, beverages, pharmaceuticals, CIP fluids, and mild chemical solutions

• Rotary Ring: Carbon, Silicon Carbide (SiC), or Tungsten Carbide (TC)

• Stationary Ring: SiC, SUS304, SUS316, or TC

• Secondary Seals: VITON®, EPDM, or NBR

• Metallic Components: SUS304/SUS316 stainless steel

* Custom material configurations are available for specific application requirements.

Operating Range:

• Temperature: -10°C to +120°C (up to 140°C for short-term SIP)

• Pressure: ≤ 1.6 MPa (16 bar)

• Speed: ≤ 3600 rpm

• Applicable Media: Water, steam, dairy products, beverages, pharmaceuticals, CIP fluids, and mild chemical solutions

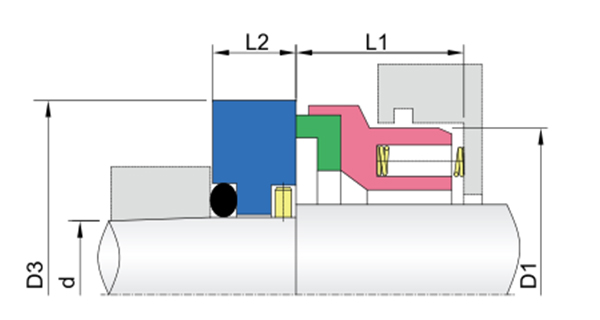

Installation Dimensions

+

| Seal Size d | D3 | D1 | L1 | L2 |

| 15.8 | 44.5 | 36.1 | 26.0 | 10.5 |

| 25.4 | 53.5 | 44.0 | 26.0 | 10.0 |

| 38.1 | 74.0 | 64.0 | 31.0 | 15.5 |

For exact dimensional specifications and compatibility confirmation with your specific INOXPA PROLAC pump, please contact our technical team with your equipment details. Our engineering support provides comprehensive technical assistance including installation guidance and maintenance recommendations to ensure optimal seal performance throughout its service life.

description2