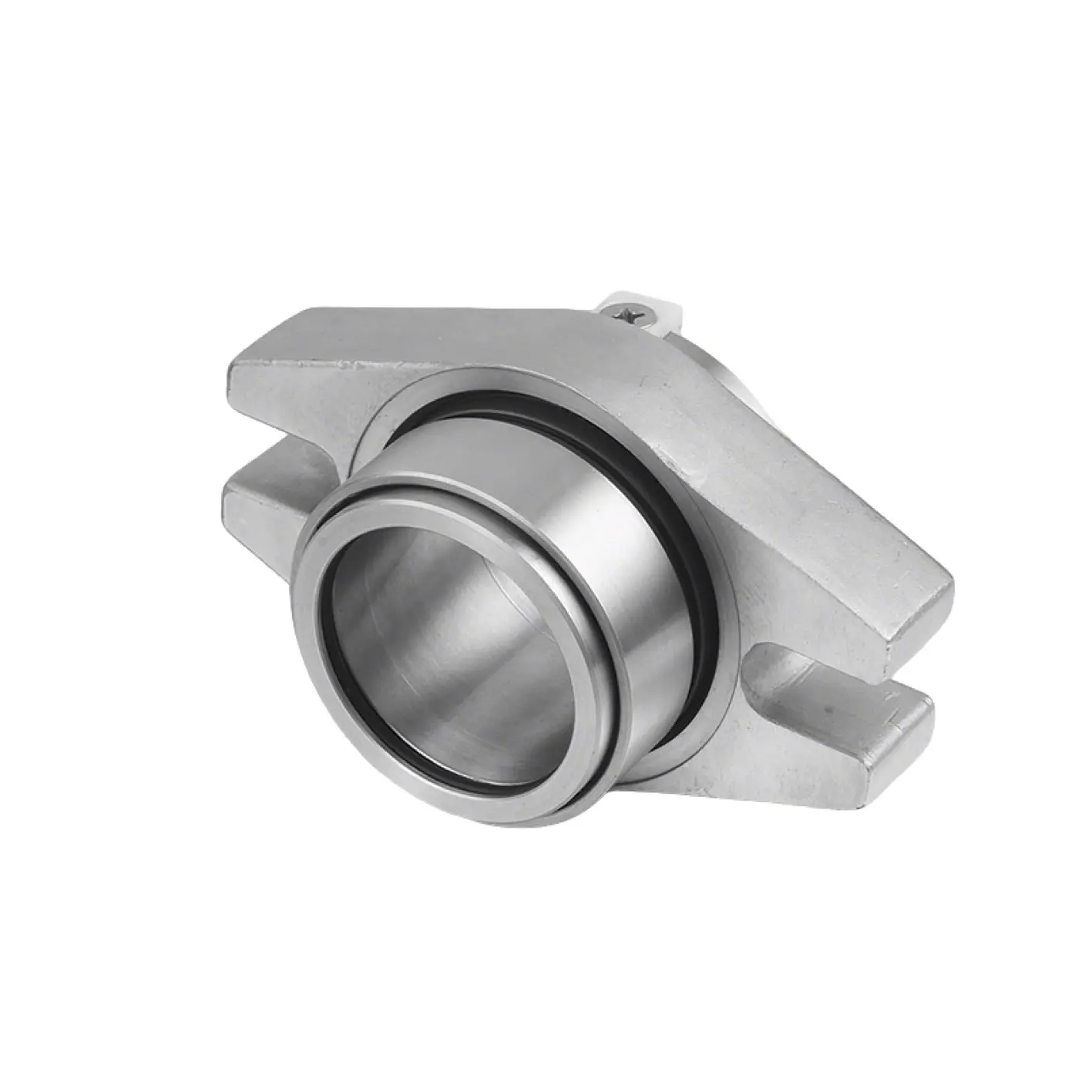

GW GU2 Cartridge Mechanical Seal AES Convertor II

The GW GU2 is a contemporary single cartridge mechanical seal engineered as a direct interchange for the AES Convertor II (CONII) series. Its optimized geometry and balanced face technology ensure reliable performance and straightforward installation across a broad range of rotating equipment.

Product Detail

This seal is manufactured to provide form, fit, and functional equivalence to the AES Convertor II cartridge seal, offering dependable performance with enhanced cost efficiency. All production is carried out under an ISO 9001 certified quality management system to guarantee consistency and reliability.

Equivalent Products

Material and Operating Range

Materials:

Operating Range:

Compatible Media:

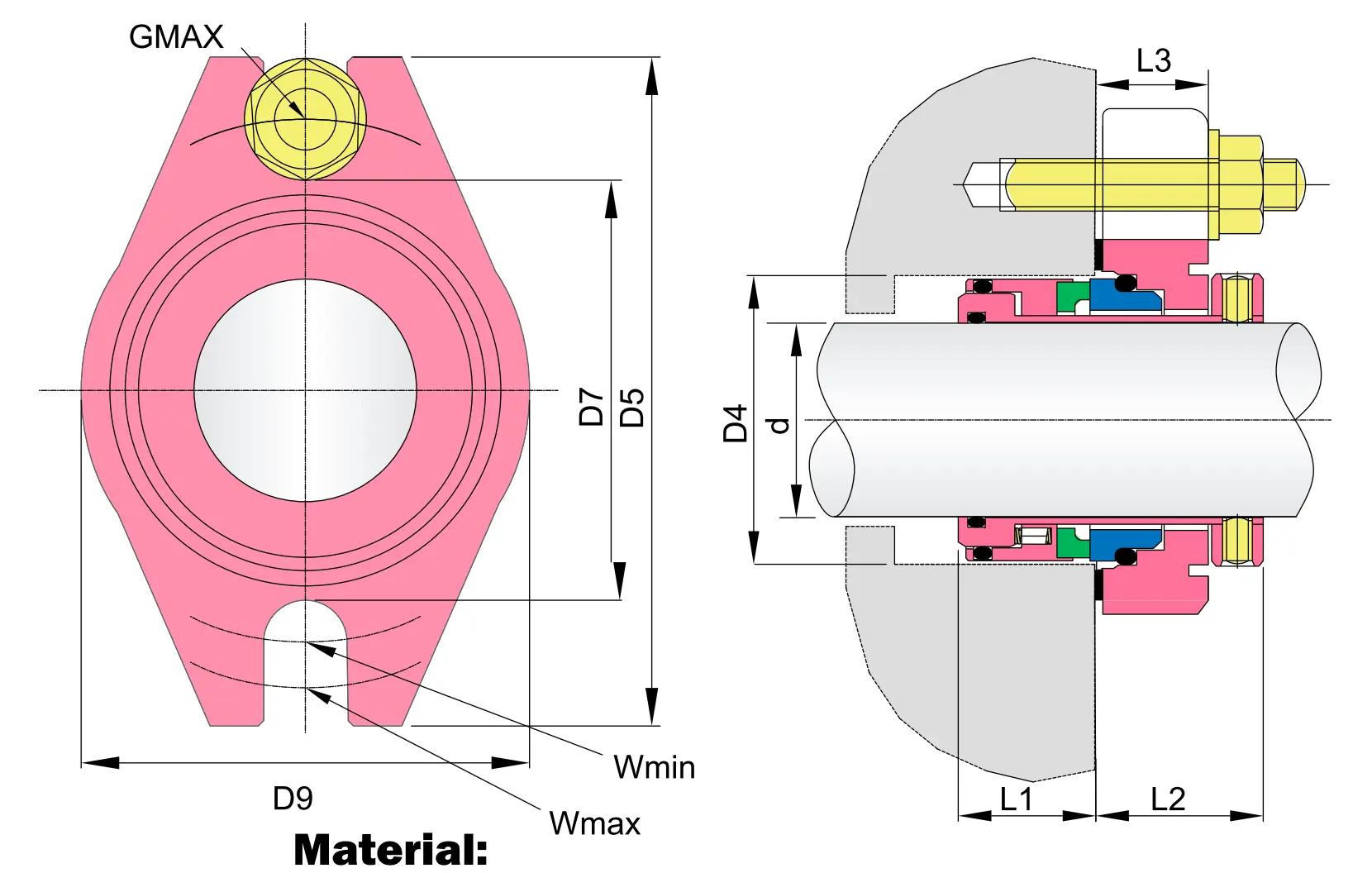

Installation Dimensions

|

Seal Size d (Metric) |

D5 |

D7 |

D9 |

L3 |

D4 |

W |

L1 |

L2 |

||

min |

max |

min |

max |

|||||||

24 |

101.6 |

55.6 |

20.7 |

56.1 |

40.0 |

48.0 |

69.9 |

88.9 |

28.6 |

31.8 |

25 |

101.6 |

55.6 |

20.7 |

56.1 |

41.0 |

48.0 |

69.9 |

88.9 |

28.6 |

31.8 |

28 |

104.8 |

58.8 |

20.7 |

59.3 |

44.0 |

50.0 |

73.1 |

92.1 |

28.6 |

31.8 |

30 |

108.0 |

61.9 |

20.7 |

62.4 |

46.0 |

54.0 |

76.2 |

95.3 |

28.6 |

31.8 |

32 |

108.0 |

61.9 |

20.7 |

62.4 |

48.0 |

54.0 |

76.2 |

95.3 |

28.6 |

31.8 |

33 |

108.0 |

61.9 |

20.7 |

62.4 |

49.0 |

55.0 |

76.2 |

95.3 |

28.6 |

31.8 |

35 |

108.0 |

66.7 |

20.7 |

67.2 |

51.0 |

59.0 |

81.0 |

95.3 |

28.6 |

31.8 |

38 |

114.3 |

71.5 |

22.3 |

72.0 |

57.2 |

62.0 |

85.8 |

101.6 |

28.6 |

33.4 |

40 |

114.3 |

71.5 |

22.3 |

72.0 |

58.0 |

64.0 |

85.8 |

101.6 |

28.6 |

33.4 |

43 |

120.7 |

74.6 |

22.3 |

75.1 |

61.0 |

67.0 |

88.9 |

108.0 |

28.6 |

33.4 |

45 |

127.0 |

77.8 |

23.8 |

78.3 |

63.5 |

69.0 |

92.1 |

114.3 |

30.2 |

35.0 |

48 |

133.4 |

81.0 |

23.8 |

81.5 |

66.7 |

72.0 |

95.3 |

120.7 |

30.2 |

35.0 |

50 |

133.4 |

81.0 |

23.8 |

81.5 |

68.0 |

74.0 |

95.3 |

120.7 |

30.2 |

35.0 |

53 |

139.7 |

84.2 |

25.4 |

84.7 |

71.0 |

77.0 |

101.6 |

123.9 |

30.2 |

36.5 |

55 |

146.1 |

87.3 |

25.4 |

87.8 |

74.0 |

79.0 |

104.8 |

130.2 |

30.2 |

36.5 |

58 |

165.1 |

95.3 |

25.4 |

98.9 |

79.4 |

85.7 |

115.9 |

146.0 |

30.2 |

36.5 |

60 |

165.1 |

95.3 |

25.4 |

98.9 |

79.4 |

85.7 |

115.9 |

146.0 |

30.2 |

36.5 |

63 |

177.8 |

111.2 |

25.4 |

121.2 |

85.8 |

101.6 |

131.8 |

158.7 |

28.6 |

41.2 |

65 |

177.8 |

111.2 |

25.4 |

121.2 |

88.9 |

101.6 |

131.8 |

158.7 |

28.6 |

41.2 |

68 |

177.8 |

111.2 |

25.4 |

121.2 |

92.1 |

101.6 |

131.8 |

158.7 |

28.6 |

41.2 |

70 |

177.8 |

111.2 |

25.4 |

121.2 |

92.1 |

101.6 |

131.8 |

158.7 |

28.6 |

41.2 |

75 |

190.5 |

125.4 |

31.7 |

130.7 |

98.5 |

114.3 |

146.1 |

171.4 |

30.2 |

50.8 |

80 |

190.5 |

125.4 |

31.7 |

130.7 |

101.6 |

114.3 |

146.1 |

171.4 |

30.2 |

50.8 |

85 |

203.2 |

135.0 |

31.7 |

140.2 |

108.0 |

123.8 |

155.6 |

184.1 |

30.2 |

50.8 |

90 |

215.9 |

144.5 |

31.7 |

149.7 |

114.3 |

133.3 |

165.1 |

196.8 |

30.2 |

50.8 |

95 |

215.9 |

144.5 |

31.7 |

149.7 |

117.5 |

133.3 |

165.1 |

196.8 |

30.2 |

50.8 |

100 |

228.6 |

154.0 |

31.7 |

156.1 |

123.9 |

139.7 |

174.7 |

209.5 |

30.2 |

50.8 |

Inch Size d |

D5 |

D7 |

D9 |

L3 |

D4 |

W |

L1 |

L2 |

||

min |

max |

min |

max |

|||||||

1.000 |

4.000 |

2.187 |

0.812 |

2.208 |

1.625 |

1.875 |

2.750 |

3.500 |

1.125 |

1.250 |

1.125 |

4.125 |

2.312 |

0.812 |

2.333 |

1.750 |

2.000 |

2.875 |

3.625 |

1.125 |

1.250 |

1.250 |

4.250 |

2.437 |

0.812 |

2.458 |

1.875 |

2.125 |

3.000 |

3.750 |

1.125 |

1.250 |

1.375 |

4.250 |

2.625 |

0.812 |

2.645 |

2.000 |

2.250 |

3.187 |

3.750 |

1.125 |

1.250 |

1.500 |

4.500 |

2.812 |

0.875 |

2.833 |

2.250 |

2.500 |

3.375 |

4.000 |

1.125 |

1.312 |

1.625 |

4.750 |

2.937 |

0.875 |

2.958 |

2.375 |

2.625 |

3.500 |

4.250 |

1.125 |

1.312 |

1.750 |

5.000 |

3.062 |

0.937 |

3.083 |

2.500 |

2.750 |

3.625 |

4.500 |

1.187 |

1.375 |

1.875 |

5.250 |

3.187 |

0.937 |

3.207 |

2.625 |

2.875 |

3.750 |

4.750 |

1.187 |

1.375 |

2.000 |

5.500 |

3.312 |

1.000 |

3.333 |

2.750 |

3.000 |

4.000 |

4.875 |

1.187 |

1.437 |

2.125 |

5.750 |

3.437 |

1.000 |

3.458 |

2.875 |

3.125 |

4.125 |

5.125 |

1.187 |

1.437 |

2.250 |

6.500 |

3.750 |

1.000 |

3.895 |

3.000 |

3.375 |

4.562 |

5.750 |

1.187 |

1.437 |

2.375 |

6.500 |

3.750 |

1.000 |

3.895 |

3.125 |

3.375 |

4.562 |

5.750 |

1.187 |

1.437 |

2.500 |

7.000 |

4.375 |

1.000 |

4.770 |

3.375 |

4.000 |

5.187 |

6.250 |

1.125 |

1.625 |

2.625 |

7.000 |

4.375 |

1.000 |

4.770 |

3.500 |

4.000 |

5.187 |

6.250 |

1.125 |

1.625 |

2.750 |

7.000 |

4.375 |

1.000 |

4.770 |

3.625 |

4.000 |

5.187 |

6.250 |

1.125 |

1.625 |

2.875 |

7.500 |

4.937 |

1.250 |

5.145 |

3.750 |

4.500 |

5.750 |

6.750 |

1.187 |

2.000 |

3.000 |

7.500 |

4.937 |

1.250 |

5.145 |

3.875 |

4.500 |

5.750 |

6.750 |

1.187 |

2.000 |

3.125 |

7.500 |

4.937 |

1.250 |

5.145 |

4.000 |

4.500 |

5.750 |

6.750 |

1.187 |

2.000 |

3.250 |

8.000 |

5.312 |

1.250 |

5.520 |

4.125 |

4.875 |

6.125 |

7.250 |

1.187 |

2.000 |

3.375 |

8.000 |

5.312 |

1.250 |

5.520 |

4.250 |

4.875 |

6.125 |

7.250 |

1.187 |

2.000 |

3.500 |

8.000 |

5.312 |

1.250 |

5.520 |

4.375 |

4.875 |

6.125 |

7.250 |

1.187 |

2.000 |

3.625 |

8.500 |

5.687 |

1.250 |

5.895 |

4.500 |

5.250 |

6.500 |

7.750 |

1.187 |

2.000 |

3.750 |

8.500 |

5.687 |

1.250 |

5.895 |

4.625 |

5.250 |

6.500 |

7.750 |

1.187 |

2.000 |

3.875 |

8.500 |

5.687 |

1.250 |

5.895 |

4.750 |

5.250 |

6.500 |

7.750 |

1.187 |

2.000 |

4.000 |

9.000 |

6.062 |

1.250 |

6.145 |

4.875 |

5.500 |

6.875 |

8.250 |

1.187 |

2.000 |

Detailed dimensional drawings for each shaft size are available upon request. Please contact our technical support team with your equipment model or shaft diameter for precise sizing information and interchange guidance.

description2