01

GW EMLL for Wilo® EMU® Submersible Pumps

This mechanical seal is engineered for reliable performance in demanding submersible pump applications. It is particularly well-suited for Wilo® EMU® series pumps in:

• Wastewater and drainage systems

• Industrial effluent and process water handling

• Stormwater and flood control applications

• General purpose dewatering systems

Product Detail

+

The GW EMLL is a high-performance OEM mechanical seal specifically configured for Wilo® EMU® FA, FK, FKT, and HC series submersible pumps. Its EBS® style push-fit design enables straightforward installation without requiring special tools or complex adjustments, significantly reducing maintenance downtime.

Engineered with fully hardened sealing faces, including silicon carbide and tungsten carbide combinations, this seal delivers exceptional durability in abrasive media commonly encountered in wastewater and industrial pumping applications. The balanced mechanical design ensures stable performance across variable pressure conditions, while the corrosion-resistant construction withstands harsh submersible environments.

Engineered with fully hardened sealing faces, including silicon carbide and tungsten carbide combinations, this seal delivers exceptional durability in abrasive media commonly encountered in wastewater and industrial pumping applications. The balanced mechanical design ensures stable performance across variable pressure conditions, while the corrosion-resistant construction withstands harsh submersible environments.

Compatibility & Equivalents

+

• Target Pumps: Wilo® EMU® FA, FK, FKT, and HC series submersible pumps

• Equivalent Models:

• AESseal®: S0ECU

• Vulcan®: 1640 & 1642

Our products can work as an alternative to the similar product of above brands with same quality but more affordable price. Our quality management follows ISO9001 standards to ensure excellent product performance.

• Equivalent Models:

• AESseal®: S0ECU

• Vulcan®: 1640 & 1642

Our products can work as an alternative to the similar product of above brands with same quality but more affordable price. Our quality management follows ISO9001 standards to ensure excellent product performance.

Material and Operating Range

+

Materials of Construction:

• Rotary Ring: Silicon Carbide (SiC) or Tungsten Carbide (TC)

• Stationary Ring: Silicon Carbide (SiC) or Tungsten Carbide (TC)

• Secondary Seals: VITON, EPDM, or NBR

• Metallic Components: SUS304/SUS316 Stainless Steel

* Custom material pairs and specific dimensions are available upon request.

Operating Range:

• Temperature: -40 ℃~200℃

• Pressure: ≤ 1.2 MPa (12 bar)

• Speed: ≤ 20m/s

• Applicable Media: wastewater, stormwater, industrial effluents, drainage water, and other mild abrasive fluids

• Rotary Ring: Silicon Carbide (SiC) or Tungsten Carbide (TC)

• Stationary Ring: Silicon Carbide (SiC) or Tungsten Carbide (TC)

• Secondary Seals: VITON, EPDM, or NBR

• Metallic Components: SUS304/SUS316 Stainless Steel

* Custom material pairs and specific dimensions are available upon request.

Operating Range:

• Temperature: -40 ℃~200℃

• Pressure: ≤ 1.2 MPa (12 bar)

• Speed: ≤ 20m/s

• Applicable Media: wastewater, stormwater, industrial effluents, drainage water, and other mild abrasive fluids

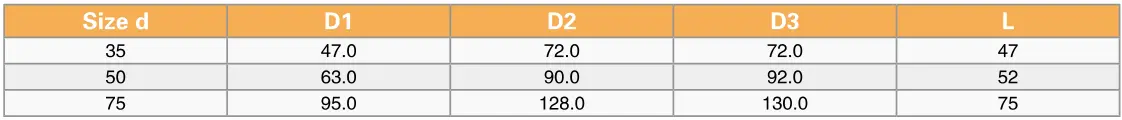

Installation Dimensions

+

description2