01

GW 290 Single spring Mechanical seal for APV ZM Series Pumps

This mechanical seal is engineered to meet the rigorous demands of sanitary fluid transfer applications. It is particularly well-suited for:

• Dairy and liquid food processing (e.g., milk, yogurt, sauces).

• Beverage and brewery transfer systems.

• Pharmaceutical and cosmetic fluid handling.

• CIP (Clean-in-Place) and SIP (Steam-in-Place) processes.

Product Description

+

The GW 290 is a high-performance OEM mechanical seal designed specifically for APV® ZM series centrifugal pumps. Its robust construction incorporates premium materials such as silicon carbide (SiC) and tungsten carbide (TC) sealing faces, which provide superior resistance to abrasion and chemical corrosion, ensuring reliable operation in continuous processing environments.

The seal’s balanced design maintains stable performance under variable pressure and temperature conditions, while the pre-assembled cartridge configuration simplifies installation and eliminates the need for specialized tools. This design minimizes maintenance interruptions and enhances operational efficiency in 24/7 production settings.

The seal’s balanced design maintains stable performance under variable pressure and temperature conditions, while the pre-assembled cartridge configuration simplifies installation and eliminates the need for specialized tools. This design minimizes maintenance interruptions and enhances operational efficiency in 24/7 production settings.

Compatibility & Equivalents

+

• Target Pumps: APV® ZM series centrifugal pumps.

• Equivalent Models:

• AESseal®: T0RVU

• Vulcan®: 29 (similar)

• Sterling®: SAPV

• Flowserve (Pac. seal) ®: APR

• Roten®: L / P / 3P

• Roplan®: R53

• Equivalent Models:

• AESseal®: T0RVU

• Vulcan®: 29 (similar)

• Sterling®: SAPV

• Flowserve (Pac. seal) ®: APR

• Roten®: L / P / 3P

• Roplan®: R53

Material and Operating Range

+

Materials:

• Rotary Ring: Carbon, Silicon Carbide (SiC), or Tungsten Carbide (TC).

• Stationary Ring: SUS304, SUS316, SiC, or TC.

• Secondary Seals: VITON®, EPDM, or NBR.

• Metallic Components: SUS304/SUS316 stainless steel.

* Custom material pairs and dimensional adjustments are available for specific application requirements.

Operating Range:

• Temperature: -40°C to +180°C (short-term peaks acceptable with specialized elastomers).

• Pressure: ≤ 0.8 MPa (8 bar).

• Speed: ≤ 15 m/s

• Applicable Media: Water, steam, dairy products, beverages, mild acids, alkaline solutions, and CIP chemicals.

• Rotary Ring: Carbon, Silicon Carbide (SiC), or Tungsten Carbide (TC).

• Stationary Ring: SUS304, SUS316, SiC, or TC.

• Secondary Seals: VITON®, EPDM, or NBR.

• Metallic Components: SUS304/SUS316 stainless steel.

* Custom material pairs and dimensional adjustments are available for specific application requirements.

Operating Range:

• Temperature: -40°C to +180°C (short-term peaks acceptable with specialized elastomers).

• Pressure: ≤ 0.8 MPa (8 bar).

• Speed: ≤ 15 m/s

• Applicable Media: Water, steam, dairy products, beverages, mild acids, alkaline solutions, and CIP chemicals.

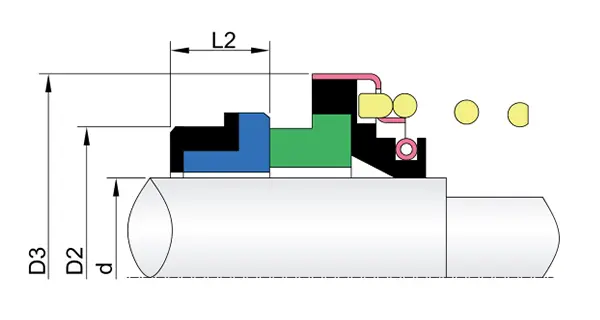

Installation Dimensions

+

For detailed dimensional schematics and guidance tailored to your APV® ZM pump model, consult our technical team with your equipment specifications. Custom shaft sizes and housing configurations are available upon request.

Size d |

D2 |

D3 |

L2 |

20 |

30.0 |

40.6 |

9.8 |

25 |

35.0 |

45.4 |

9.8 |

30 |

42.0 |

57.0 |

13.0 |

description2