Fristam Pump Seals | Quality Seals from Top Manufacturers in China

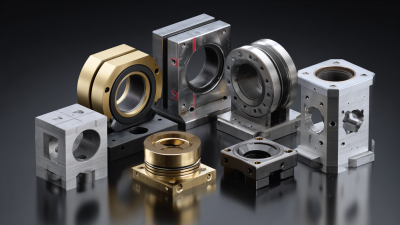

In the mechanical seal industry, quality and reliability are paramount for pump solutions. Our fristam pump seal is meticulously engineered to deliver optimal performance and longevity, making it suitable for a variety of industrial applications. Manufactured in Ningbo, China, our products benefit from cutting-edge technology and rigorous quality control protocols. Choosing our fristam pump seal means investing in a product that adheres to international standards, ensuring you can operate with confidence. We offer a detailed pricelist tailored for B2B buyers to guarantee exceptional value. Whether managing a large enterprise or a small startup, our seals are designed to effectively meet your operational requirements. Contact us for a quote and see the difference firsthand!

Methods To choose fristam pump seal Where Service Meets Innovation Where Innovation Meets 2025

Selecting the right Fristam pump seal is crucial for ensuring optimal efficiency and longevity in your operations. As we move towards 2025, innovation plays a vital role in redefining these choices. It’s essential to understand the intersection of service and innovation. Begin by evaluating the specific requirements of your application—consider factors such as fluid type, pressure, and temperature. Advanced seals are designed to minimize leakage and withstand challenging operational environments, thereby enhancing the overall productivity of your system. Emphasizing efficiency, opting for seals that combine innovative materials and design principles can significantly reduce maintenance costs and downtime. Collaborating with manufacturers who prioritize R&D can provide insights into the latest technological advancements that complement modern pump systems. As the industry continues evolving, make it a priority to choose partners that not only deliver high-quality products but also excel in customer service, ensuring that you receive timely support and solutions tailored to your unique needs. This alignment of service and innovative technology will lead to more sustainable and effective operations, setting your business on the path to success.

Methods To Choose Fristam Pump Seal: Where Service Meets Innovation Where Innovation Meets 2025

| Method | Description | Benefits | Potential Challenges | Innovation Impact |

|---|---|---|---|---|

| Material Analysis | Evaluating seal materials based on operational conditions. | Enhanced durability and performance. | Availability of materials may vary. | Leads to improved material science innovation. |

| Performance Testing | Conducting tests to measure seal performance under pressure. | Real-world performance validation. | Testing equipment costs can be high. | Encourages innovation in testing technologies. |

| Feedback Loop | Gathering user experiences to refine selection methods. | Tailored solutions based on end-user input. | Sustaining feedback can be difficult. | Inspires user-centric innovation approaches. |

| Cross-Industry Collaboration | Partnering with other industries to innovate. | Access to diverse expertise and technologies. | Aligning goals across industries can be complex. | Promotes cross-disciplinary innovation. |

| Simulation Software | Using software to model seal behavior under different conditions. | Reduces the need for physical prototypes. | Dependent on the accuracy of the software. | Enhances digital innovation in design processes. |

Why fristam pump seal Custom Solutions, Pioneers in the Field

D

David Lee

High-quality product! I had a few queries after my purchase, and the customer service team was incredibly professional and quick to respond.

01 June 2025

S

Sophia Howard

Incredible quality from start to finish! The follow-up service was impeccable, featuring a friendly and professional team.

02 June 2025

E

Ella Ross

Such a high-quality product! I was impressed by the professionalism of the customer service personnel.

24 May 2025

M

Mia Davis

Top-tier quality! I was thrilled with the assistance provided by the support team—they were very thorough.

28 June 2025

M

Matthew Baker

Outstanding quality! The support team was incredibly helpful and offered professional service throughout my experience.

10 June 2025

L

Lucas Thomas

Fantastic quality product! The support team was helpful and handled my inquiries with professionalism.

14 May 2025