Flygt Pump Seal for Heavy-Duty Slurry and Wastewater Applications

This mechanical seal is engineered specifically for Flygt pumps with a 60mm shaft diameter, delivering reliable sealing under demanding conditions such as wastewater management, mining operations, and industrial slurry transport. Its robust design ensures long-term performance, even with highly abrasive media and continuous operation.

Product Detail

By utilizing metal-to-metal secondary sealing, this mechanical seal eliminates vulnerabilities associated with elastomer degradation in harsh environments. It provides a dependable sealing solution for pumps handling slurries, chemicals, and wastewater, contributing to extended pump lifespan and reduced operational downtime.

Equivalent Products

Our mechanical seals offer a cost-efficient alternative to OEM components while matching original dimensional and performance specifications. All products are manufactured under stringent ISO9001 quality control systems to ensure reliability, durability, and consistent performance.

Construction Materials

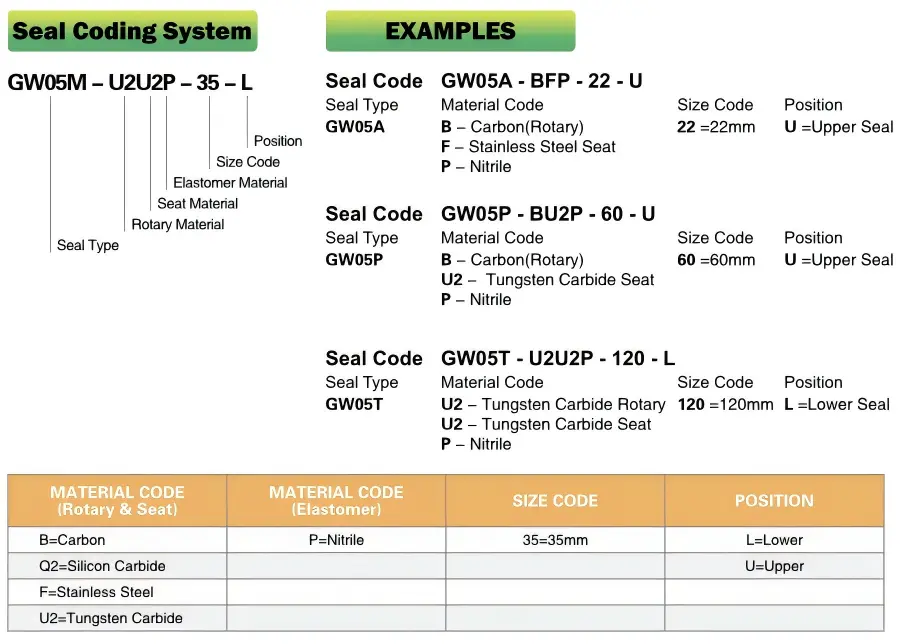

Upper Seal Assembly: GW05Q-F-BU2P-60-U

• Rotary Component: Carbon

• Stationary Seat: Stainless Steel

• Elastomer: Nitrile Rubber

Lower Seal Assembly: GW05Q-F-U2U2P-60-L

• Rotary Face: Tungsten Carbide

• Stationary Seat: Tungsten Carbide

• Elastomer: Nitrile Rubber

Seal Coding System

* Custom material and parameter configurations are available upon request. Contact our technical team for tailored solutions.

Operating and Application Range

Operating Parameters:

• Maximum Pressure: ≤ 1.2 MPa

• Temperature Range: -30 ℃ to +200 ℃

• Maximum Peripheral Speed: ≤ 10 m/s

Application Range:

• Municipal and Industrial Wastewater Treatment

• Mining, Mineral, and Slurry Processing

• Chemical and Industrial Fluid Handling

• Pump Repair, Seal Replacement, and Maintenance Services

Installation Dimensions

description2