Dual-Seal Assembly GW 92B-35 for Alfa Laval Centrifugal Pump

This OEM dual-seal assembly is engineered to meet the rigorous demands of Alfa Laval centrifugal pumps in applications where extra leakage prevention is critical. It is ideal for use in:

• Hazardous fluid transfer systems

• High-purity pharmaceutical processing

• Food and beverage production with strict hygiene standards

• Chemical and solvent handling

• Sanitary processing and CIP systems

Product Detail

Constructed with wear-resistant face materials and stainless steel components, this seal maintains reliable operation under varying pressure and temperature conditions. Its balanced design supports consistent face contact and extended service life in continuous duty environments.

Validated Equipment Compatibility:

• Alfa Laval centrifugal pumps configured for double mechanical seals

• Hygienic and aseptic fluid transfer systems

• Processes requiring 35mm shaft sealing solutions

Please contact us with your project details for pricing and technical support.

Equivalent Products

• Roplan®: RTH81/82/84

*Our seals are fully compatible with the above references and provide equivalent performance with ISO9001-certified manufacturing for assured quality and durability.

Material and Operating Range

Material:

• Rotary seal face: Carbon (Resin Impregnated Carbon Graphite)/Silicon Carbide (SiC)

• Stationary seal face: SUS304/SUS316/SiC/Tungsten Carbide (TC)

• Secondary seal: VITON/ EPDM

• Springs and metal parts: SUS304/SUS316

* Custom material combinations and dimensional adjustments are available upon request.

Operating Range:

• Temperature: -20ºC to +180ºC

• Pressure: up to 2.5MPa

• Rotational Speed: ≤15m/s

Suitable Media:

• Pharmaceutical liquids and solvents

• Food-grade ingredients and cleaning agents

• Chemical and process fluids

• Industrial oils and coolants

• Hot water and steam

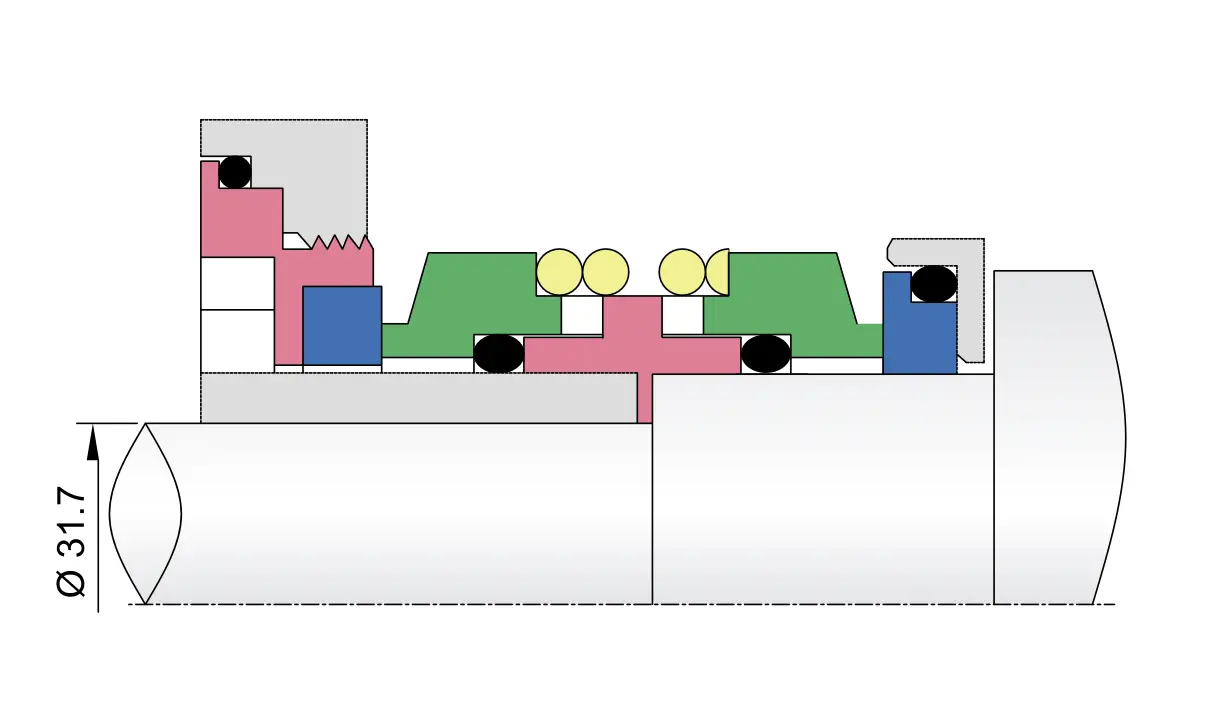

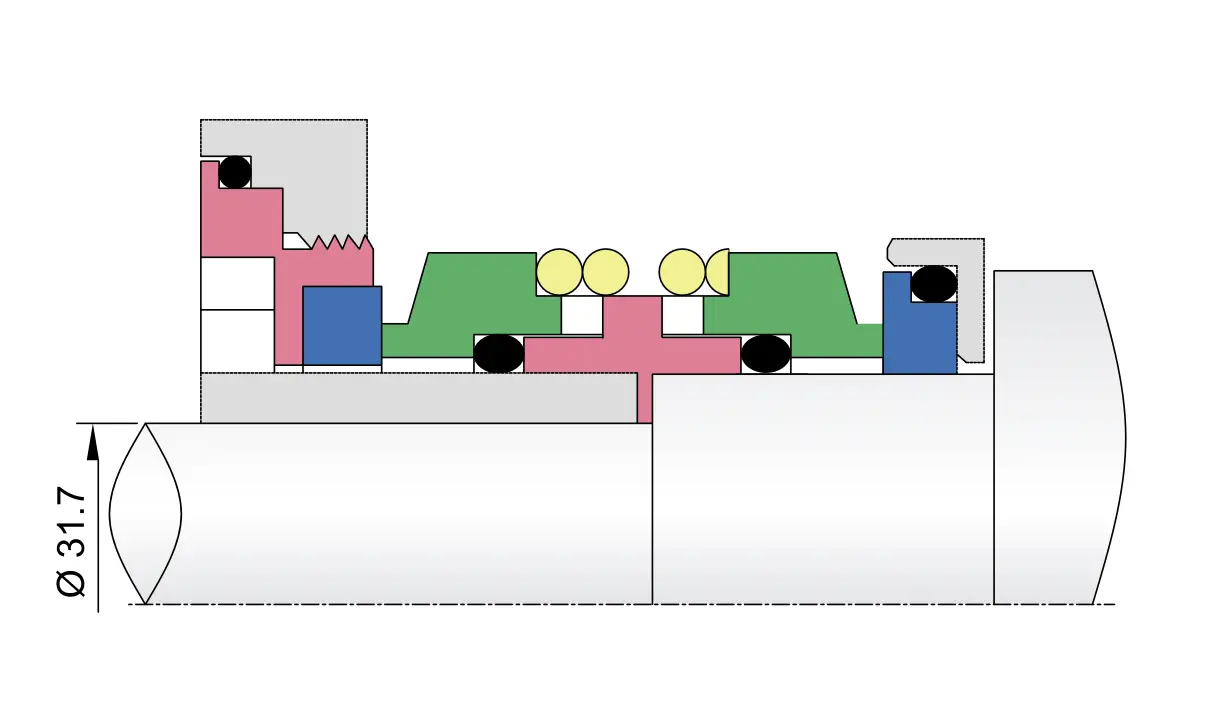

Installation Dimensions

description2