Chemical Process Wave Spring O-ring Seals Type 1677 Replacement

This universal mechanical seal delivers reliable performance in high-torque viscous applications across multiple industries:

• Chemical processing systems (acid/solvent transfer)

• Pulp & paper production equipment

• Water and sewage pumping stations

• General rotating machinery (pumps, mixers, agitators)

Product Description

• Wave spring technology ensures uniform sealing pressure

• Hex-key set screw drive provides positive shaft engagement

• Integrated face design resists media extrusion

• Full compliance with DIN 24960/EN 12756 L1K-U standards

This mechanical seal component achieves ±2.5mm axial movement compensation through its sinusoidal wave spring, effectively absorbing shaft displacement during thermal transients and vibration cycles. This design delivers 15% higher pV capability compared to conventional spring seals, reducing heat generation in heavy-duty services. Engineered for chemical and pulp industry reliability.

Validated Equipment Fit:

• Apex TD 32-200.B/S

• Flowserve 100-65CPX160/200 series

• Others rotating equipment

Equivalent Products

• EagleBurgmann®: Type M78N

• Vulcan®: Type 1677

• Pac-seal®: Type 167

• Sterling®: Type 270

We also provide related wave spring mechanical seals products such as 1688/ 1688Z/ 1688W/ 1688L/ 1682, please contact us or refer to the product catalogue for more detail.

*Cost-efficient ISO9001-certified alternatives with identical dimensional specifications.

Material and Operating Range

Construction Materials:

• Rotary ring: Carbon/ Silicon Carbide (SiC)/Tungsten Carbide (TC)

• Stationary ring: 99%Ceramic/SiC/TC

• O-ring: VITON/NBR/EPDM

• Spring and Metal Parts: SUS304/SUS316

* Custom Solutions:

Specialized configurations available for non-standard shaft sizes and materials.

Operating Parameters:

• Temperature: -30 ℃~200℃

• Pressure: ≤2MPa

• Speed: ≤20m/s

• Corrosion Resistance: Moderate

Compatible Media:

• Industrial oils & solvents

• Process water & sewage

• Pulp and paper suspensions

• Moderately corrosive chemicals

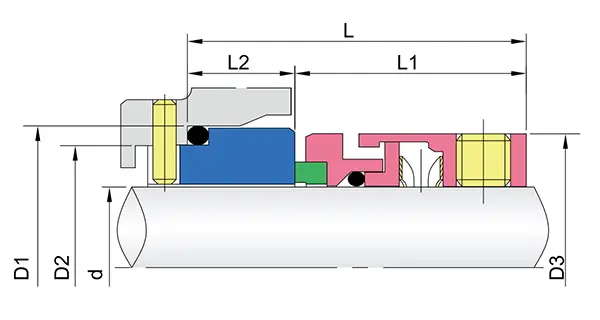

Installation Dimensions

| Seal Size d | D1 | D2 | D3 | L1 | L2 | L |

| 14 | 25.0 | 21.0 | 24.0 | 25.0 | 10.0 | 35.0 |

| 16 | 27.0 | 23.0 | 26.0 | 25.0 | 10.0 | 35.0 |

| 18 | 33.0 | 27.0 | 32.0 | 26.0 | 11.5 | 37.5 |

| 20 | 35.0 | 29.0 | 34.0 | 26.0 | 11.5 | 37.5 |

| 22 | 37.0 | 31.0 | 36.0 | 26.0 | 11.5 | 37.5 |

| 24 | 39.0 | 33.0 | 38.0 | 28.5 | 11.5 | 40.0 |

| 25 | 40.0 | 34.0 | 39.0 | 28.5 | 11.5 | 40.0 |

| 28 | 43.0 | 37.0 | 42.0 | 31.0 | 11.5 | 42.5 |

| 30 | 45.0 | 39.0 | 44.0 | 31.0 | 11.5 | 42.5 |

| 32 | 48.0 | 42.0 | 46.0 | 31.0 | 11.5 | 42.5 |

| 33 | 48.0 | 42.0 | 47.0 | 31.0 | 11.5 | 42.5 |

| 35 | 50.0 | 44.0 | 49.0 | 31.0 | 11.5 | 42.5 |

| 38 | 56.0 | 49.0 | 54.0 | 31.0 | 14.0 | 45.0 |

| 40 | 58.0 | 51.0 | 56.0 | 31.0 | 14.0 | 45.0 |

| 43 | 61.0 | 54.0 | 59.0 | 31.0 | 14.0 | 45.0 |

| 45 | 63.0 | 56.0 | 61.0 | 31.0 | 14.0 | 45.0 |

| 48 | 66.0 | 59.0 | 64.0 | 31.0 | 14.0 | 45.0 |

| 50 | 70.0 | 62.0 | 66.0 | 32.5 | 15.0 | 47.5 |

| 53 | 73.0 | 65.0 | 69.0 | 32.5 | 15.0 | 47.5 |

| 55 | 75.0 | 67.0 | 71.0 | 32.5 | 15.0 | 47.5 |

| 58 | 78.0 | 70.0 | 78.0 | 37.5 | 15.0 | 52.5 |

| 60 | 80.0 | 72.0 | 80.0 | 37.5 | 15.0 | 52.5 |

| 63 | 83.0 | 75.0 | 83.0 | 37.5 | 15.0 | 52.5 |

| 65 | 85.0 | 77.0 | 85.0 | 37.5 | 15.0 | 52.5 |

| 68 | 90.0 | 81.0 | 88.0 | 34.5 | 18.0 | 52.5 |

| 70 | 92.0 | 83.0 | 90.0 | 42.0 | 18.0 | 60.0 |

| 75 | 97.0 | 88.0 | 99.0 | 42.0 | 18.0 | 60.0 |

| 80 | 105.0 | 95.0 | 104.0 | 41.8 | 18.2 | 60.0 |

| 85 | 110.0 | 100.0 | 109.0 | 41.8 | 18.2 | 60.0 |

| 90 | 115.0 | 105.0 | 114.0 | 46.8 | 18.2 | 65.0 |

| 95 | 120.0 | 110.0 | 119.0 | 47.8 | 17.2 | 65.0 |

| 100 | 125.0 | 115.0 | 124.0 | 47.8 | 17.2 | 65.0 |

description2