Bellow Seals Replace John Crane Type 1 Multi-purpose Water Pump

Industrial Sealing Solutions:

This multi-purpose elastomer bellow seal delivers reliable performance across diverse media - from process water sealing to steam applications and chemical-resistant sealing.

• Pulp & paper stock agitator seals

• Petrochemical compressor shaft seals

• Food-grade elastomer bellows seals

• Wastewater treatment bellow seals

• Power generation turbine seals

• Chemical pump seals

Engineered for longtime mechanical seal service in critical industries

Product Description

• Positive drive system: Rubber diaphragm bellows clamp shafts securely

• Constant face pressure: Parallel springs maintain contact force

• Stress-free operation: Drive band and notches prevent excessive stress

This component is available in metric and inch sizes and follows the standard EN 12756, compatible with the A-C Pump 2-1/2X2 SLH, A-C Pump 3X2 MM-2, A-C Pump 3X2-1/2 SLH and others equipment.

Its stationary GWT11 suits common USA market imperial extended-length seal chambers.

Equivalent Products

• Roten®: 51A

• Vulcan®: Type A5

• JohnCrane®: Type 1 (USA)

• EagleBurgmann®: Type MG901

• Flowserve Pac-Seal ®: Type 51

• Flexaseal®: Type 1

• Lidering®: Type LRB00U

• U.S. Seal®: Type E

*We provide certified ISO9001 mechanical seal solutions with identical dimensions at competitive prices.

Material and Operating Range

Material:

• Rotary ring: Carbon/SiC/TC

• Stationary ring: 99% Ceramic /SiC/TC

• O-ring: VITON/NBR/EPDM

• Spring and Metal Parts: SUS304/SUS316

* Customization for this part is supported, please contact us for changing parameters and materials.

Operating Range:

• Temperature: -40 ℃~180℃

• Pressure: ≤2.5 MPa

• Speed: ≤18 m/s

• Performance: Low-wear operation

Compatible Mediums:

• Hydraulic oils

• Process water & sewage

• Paper pulp slurries

• Food-grade fluids

• Organic/inorganic chemicals

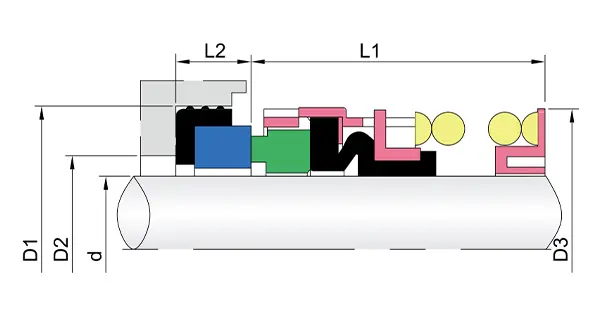

Installation Dimensions

| Inches Size | Metric Size | D1 | D2 | D3 | L1 | L2 |

| 0.500 | 12 | 25.40 | 19.05 | 23.80 | 30.16 | 7.93 |

| 14 | 31.75 | 23.80 | 27.76 | 33.32 | 10.28 | |

| 0.625 | 16 | 31.75 | 23.80 | 27.76 | 33.32 | 10.28 |

| 0.750 | 18 | 34.93 | 26.98 | 30.94 | 33.32 | 10.28 |

| 20 | 38.10 | 30.15 | 34.11 | 34.93 | 10.28 | |

| 0.875 | 22 | 38.10 | 30.15 | 34.11 | 34.93 | 10.28 |

| 24 | 41.28 | 33.32 | 38.10 | 39.67 | 11.10 | |

| 1.000 | 25 | 41.28 | 33.32 | 38.10 | 39.67 | 11.10 |

| 1.125 | 28 | 44.44 | 36.50 | 41.28 | 41.28 | 11.10 |

| 30 | 47.63 | 37.90 | 46.02 | 41.28 | 11.10 | |

| 1.250 | 32 | 47.63 | 37.90 | 46.02 | 41.28 | 11.10 |

| 33 | 50.80 | 42.84 | 48.68 | 42.85 | 11.00 | |

| 1.375 | 35 | 50.80 | 42.84 | 48.68 | 42.85 | 11.00 |

| 1.500 | 38 | 53.98 | 46.05 | 51.85 | 42.85 | 11.00 |

| 1.625 | 40 | 60.38 | 50.80 | 58.10 | 50.80 | 12.70 |

| 43 | 63.50 | 53.97 | 61.27 | 50.80 | 12.70 | |

| 1.750 | 45 | 63.50 | 53.97 | 61.27 | 50.80 | 12.70 |

| 1.875 | 48 | 66.68 | 57.15 | 64.44 | 53.98 | 12.70 |

| 48 | 69.85 | 60.32 | 67.21 | 53.98 | 12.70 | |

| 2.000 | 50 | 69.85 | 60.32 | 67.21 | 53.98 | 12.70 |

| 2.125 | 53 | 76.20 | 60.32 | 72.02 | 60.33 | 14.28 |

| 2.250 | 55 | 79.38 | 61.90 | 75.30 | 60.33 | 14.28 |

| 2.375 | 60 | 82.55 | 67.39 | 78.30 | 63.50 | 14.28 |

| 2.500 | 63 | 85.73 | 68.25 | 81.54 | 63.50 | 14.28 |

| 2.625 | 65 | 85.73 | 71.24 | 86.22 | 69.85 | 15.90 |

| 2.750 | 70 | 88.90 | 74.60 | 89.40 | 73.03 | 15.90 |

| 2.875 | 73 | 95.25 | 77.77 | 92.57 | 73.03 | 15.90 |

| 3.000 | 75 | 98.43 | 80.95 | 95.75 | 73.03 | 15.90 |

| 3.125 | - | 101.60 | - | 101.60 | 79.38 | 19.84 |

| 3.250 | - | 104.78 | - | 104.80 | 79.38 | 19.84 |

| 3.375 | - | 107.95 | - | 107.90 | 79.38 | 19.84 |

| 3.500 | - | 111.13 | - | 111.00 | 79.38 | 19.84 |

| 3.625 | - | 114.30 | - | 114.30 | 82.55 | 19.84 |

| 3.750 | - | 117.48 | - | 117.48 | 82.55 | 19.84 |

| 3.875 | - | 120.65 | - | 120.65 | 85.73 | 19.84 |

| 4.000 | - | 123.83 | - | 123.80 | 85.73 | 19.84 |

description2