01

Balanced Elastomer Seal John Crane Type 1B for Water Pump

Product Description

+

This component is a variant of GW1, which is a robust rubber diaphragm seal designed with self-adjusting seal head and mounted parallel spring. The drive of the shaft is achieved by a diaphragm bellows clamping the shaft tightly and providing positive drive to the seal head and sealing face. Its diaphragm seal design protects the shaft and sleeve from wear and scoring as the spring provides constant forces to the contact point, while the drive band and notches eliminate excessive stress on the bellows.

Its stationary suits common USA market imperial extended-length seal chambers.

Its stationary suits common USA market imperial extended-length seal chambers.

Equivalent Products

+

• JohnCrane®: Type 1B

Our products can work as an alternative to the similar product of above brands with same quality but more affordable price. Our quality management follows ISO9001 standards to ensure excellent product performance.

Our products can work as an alternative to the similar product of above brands with same quality but more affordable price. Our quality management follows ISO9001 standards to ensure excellent product performance.

Material and Operating Range

+

Material:

• Rotary ring: Carbon/SiC/TC

• Stationary ring: 99% Ceramic /SiC/TC

• O-ring: VITON/NBR/EPDM

• Spring and Metal Parts: SUS304/SUS316

* The stationary seat is GWT11

* Customization for this part is supported, please contact us for changing parameters and materials.

Operating Range:

• Temperature: -40 ℃~180℃

• Pressure: ≤8 MPa

• Speed: ≤18 m/s

• Performance: Less wear

Mediums:

• Oil

• Water

• Sewage water

• Pulp and paper

• Food

• Chemical contents

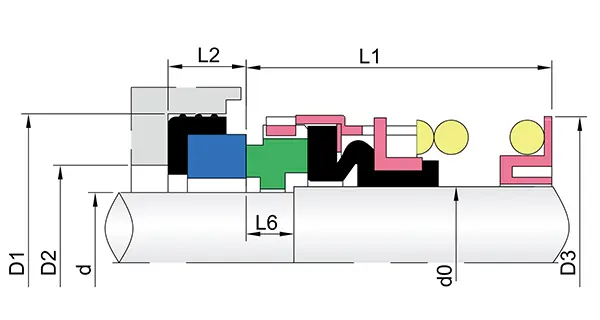

Installation Dimensions

+

| Inches Size | d0 | d | D3 | D2 | D1 | L1 | L2 | L6 |

| 1.000 | 25.40 | 22.20 | 38.10 | 33.32 | 38.10 | 47.63 | 10.31 | 8.70 |

| 1.125 | 28.50 | 25.40 | 41.28 | 36.50 | 41.20 | 49.20 | 11.10 | 8.70 |

| 1.250 | 31.70 | 28.50 | 46.02 | 39.70 | 44.44 | 49.20 | 11.10 | 8.70 |

| 1.375 | 34.90 | 31.70 | 47.63 | 42.84 | 47.63 | 50.80 | 11.10 | 8.70 |

| 1.500 | 38.10 | 34.90 | 50.80 | 46.05 | 50.80 | 50.80 | 11.10 | 8.70 |

| 1.625 | 41.20 | 38.10 | 57.15 | 50.80 | 53.98 | 60.33 | 12.70 | 11.10 |

| 1.750 | 44.40 | 41.20 | 60.33 | 53.97 | 60.33 | 60.33 | 12.70 | 11.10 |

| 1.875 | 47.60 | 44.40 | 63.50 | 57.15 | 63.50 | 63.50 | 12.70 | 11.10 |

| 2.000 | 50.80 | 47.60 | 66.68 | 60.32 | 66.68 | 63.50 | 12.70 | 11.10 |

| 2.125 | 53.90 | 50.80 | 71.42 | 60.32 | 69.85 | 69.85 | 14.27 | 12.70 |

| 2.250 | 57.10 | 53.90 | 74.60 | 61.90 | 76.20 | 69.85 | 14.27 | 12.70 |

| 2.375 | 60.30 | 57.10 | 77.77 | 67.39 | 79.38 | 73.03 | 14.27 | 12.70 |

| 2.500 | 63.50 | 60.30 | 80.95 | 68.25 | 82.55 | 73.03 | 14.27 | 12.70 |

| 2.625 | 66.60 | 63.50 | 85.73 | 71.42 | 85.73 | 79.38 | 15.88 | 14.27 |

| 2.750 | 69.80 | 66.60 | 88.90 | 74.60 | 85.73 | 79.38 | 15.88 | 14.27 |

| 2.875 | 73.00 | 69.80 | 92.08 | 77.77 | 88.90 | 82.55 | 15.88 | 14.27 |

| 3.000 | 76.20 | 73.00 | 95.25 | 80.95 | 95.25 | 82.55 | 15.88 | 14.27 |

| 3.125 | 79.30 | 73.20 | 101.60 | 84.12 | 95.25 | 88.90 | 19.84 | 15.88 |

| 3.250 | 82.50 | 76.20 | 104.78 | 87.30 | 98.43 | 88.90 | 19.84 | 15.88 |

| 3.375 | 85.70 | 79.30 | 107.95 | 90.47 | 101.60 | 88.92 | 19.84 | 15.88 |

| 3.500 | 88.90 | 82.50 | 111.13 | 93.65 | 104.78 | 88.90 | 19.84 | 15.88 |

| 3.625 | 92.00 | 85.70 | 114.30 | 96.82 | 107.95 | 92.08 | 19.84 | 15.88 |

| 3.750 | 95.20 | 88.90 | 117.48 | 100.00 | 111.13 | 92.08 | 19.84 | 15.88 |

| 3.875 | 98.40 | 92.00 | 120.65 | 103.17 | 114.30 | 95.25 | 19.84 | 15.88 |

| 4.000 | 101.60 | 95.20 | 123.83 | 106.35 | 117.48 | 95.25 | 19.84 | 15.88 |

description2